Case Study

Heidenhain TNC Controls Streamline Mold Manufacturing and Global Connectivity

Five-axis machines with the right controls are a key part of a connected system that yields better, faster work.

Read MoreCoupler Lends Easy, Reliable Solution to Quick Mold Change

A coupler helps provide a faster, more reliable way to tie positive return ejection into a mold.

WatchCNC Machining Cell with Robot Elevates Production and Savings

Cooper Tires speeds tire-mold production with advanced CNC machining and automation technologies.

WatchCNC Deep-Hole Drilling with Milling Transforms 2D Machining

Midwest Mold Services dramatically reduced costs and lead times with investment in new multitasking CNC machine.

WatchLinear Motor Drive on Sinker EDM Machine Speeds Productivity

Linear motor technology in a sinker EDM machine enables Action Mold and Engineering to burn faster, more efficiently and more economically with minimal maintenance.

Read MoreMold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

Read MoreDetermination and Skill Save Critical Micro-Mold Cavity

Team 1 Plastics Inc. found a new supplier “soul mate” in Alliance Specialties and Laser Sales (Wauconda, Illinois), which displayed a commitment to, and the skills for, a successful micro-mold cavity repair solution.

Read MoreSingle CAD/CAM System Delivers a Complete Process

Tebis CAD/CAM is a single software system that delivers a complete process from design to finished product with automation, simulation and individual modules.

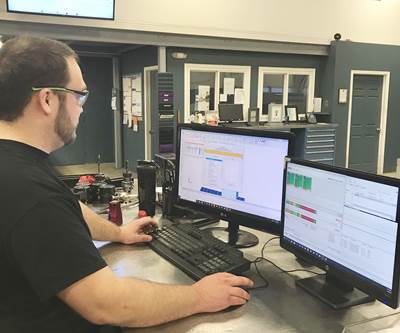

Read MoreMachine Monitoring Software Optimizes TK Mold and Engineering’s Productivity

TK Mold and Engineering Inc. President Tom Barr says his company makes more strategic, effective decisions about its day-to-day operations and workforce needs because it uses InFocus software from R.E.R. Software Inc.

Read More"Common Sense Manufacturing" Concept Drives Efficiencies at Byrne Tool

A 100-percent commitment to Common Sense Manufacturing (CSM) has helped Byrne Tool + Design reduce waste on multiple levels and drive improvements and growth.

Read More

.png;maxWidth=300;quality=90)