3D Printing

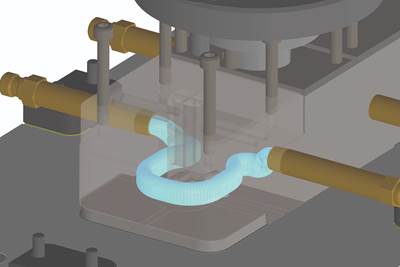

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

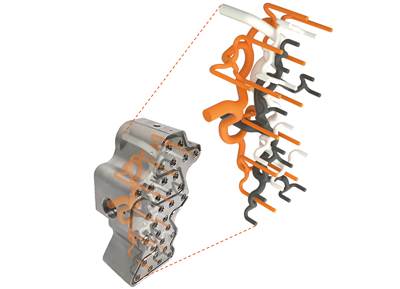

Read MoreHot Runner Manifold Offers Increased Flexibility

Hasco’s additively manufactured Steamrunner hot runner manifold allows for increased flexibility with injection molding.

Read MoreSociety of Plastics Engineers Acquires 3Dnatives, Expands Additive Manufacturing Expertise

3Dnative, a leading global media and event platform, will broaden SPE’s global reach through daily industry news and distinct market-specific platforms produced in five native languages.

Read MoreNext Chapter Manufacturing Expands Into Medical Industry, Initiates NXCMED

Additive surgical company will deliver surgical device solutions, such as implants and complex surgical devices, through disruptive design and 3D printing technologies.

Read More3D-Printed Tooling Workflow Achieves Complex Part Prototyping

Addifab freeform injection molding (FIM) simplifies design and delivery of injection-molded test parts through scaled production of 3D-printed mold cores and cavities compatible with any molding feedstock.

WatchPTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

Read MoreWestminster Tool Metal 3D Printing Technology Celebrated by Leaders, State Officials

Westminster Tool hosted politicians, educators, administrators and workforce development organizations to showcase its Mantle beta machine.

Read MoreMetal AM Advances in Composite Tooling

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreHow Additive Manufacturing Can Help, Not Hinder, Injection Moldability of New Designs

Four cost drivers — design for moldability, mold base size, internal componentry and polish/custom finishing — dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding potential pitfalls.

Read More