Mold Software Gives Shops a Proactive Approach to Maintenance Tracking

MoldTrax releases feature updates to its MTLinX documentation tracking system to ensure your shop’s molds are running as efficiently and reliably as possible.

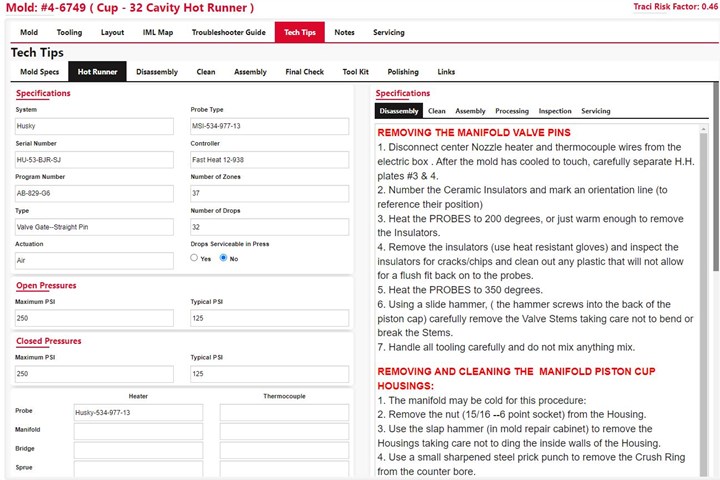

MoldTrax LLC presents MTLinX, the newest version of its popular documentation tracking system. MoldTrax contends that MTLinX is the only mold maintenance program created specifically for efficient tracking of the performance, maintenance efficiency and repair costs of injection, rubber, blow and die-cast, stamping, cutting and forming dies. MoldTrax’s distinctive architecture enables the use of a shop’s standard terminology throughout the system instead of typical, confusing journal entries that conventional systems may use.

One new feature is MTLinX’s expanded global version, which allows an OEM the visibility and tools to independently manage multiple molding locations around the globe through one database, and in eight different languages.

MTLinX users can also now connect their ERP, press or other processing systems for seamless data entry. Moreover, they now have the ability to set four levels of preventative maintenance (PM) based on cycles or calendar dates. An expanded PM “Alert” module shows approaching or overdue PM’s (green, yellow or red) in live time using cycles, hours and days.

An expanded Hot Runner section now includes instruction fields for disassembly, cleaning, inspecting and tracking hot runner components and the ability to “link” to outside sources for images and ordering replacement components

Finally, the MTLinX Mold Performance Dashboard automatically displays a shop’s top 10 frequencies and costs for tooling, labor and quality issues in one facility or across all its molders.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.