RJG and Key Up Education Offer Field Trips

Third graders enjoyed field trips to an injection molding lab, allowing them to connect with math and science in the real world.

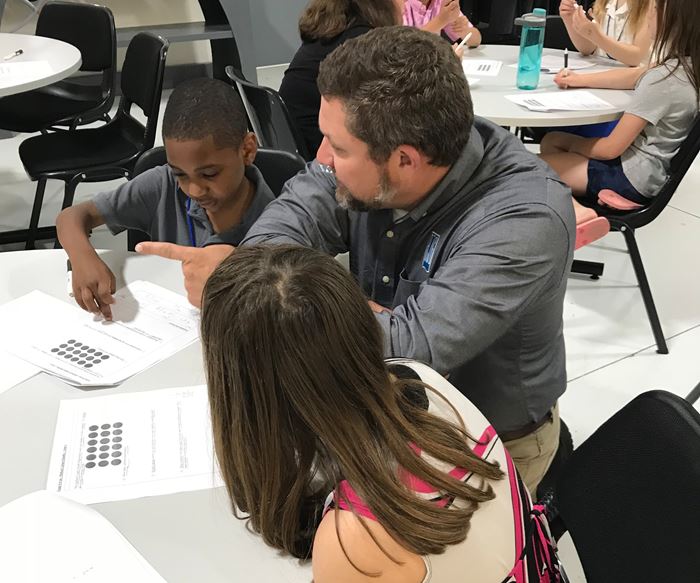

On May 4, 2018, RJG and Key Up Education hosted a one-of-a-kind educational field trip for 42 third-grade students from Sylvan Elementary at RJG’s Gibsonville, North Carolina training center. The goal was to incorporate the math and science skills the students are learning in class and show how they are used in a real-world setting through hands-on activities and problem solving.

What makes these field trips unique is that RJG and Key Up Education communicate with the teachers beforehand and create custom activities to reflect the class’s current curriculum. The day is targeted directly at what the teacher’s content is in the classroom and adjusted to anything he/she wants them to focus on—it is a day designed around what the kids need more exposure to.

The goal of these field trips is two-fold: 1. to show students at a young age how what they’re learning in school applies to the real world and get them excited about math and science, and 2. to plant a seed so hopefully more students will consider a career in manufacturing to help bridge the skills gap the industry is currently facing.

The field trips are centered around third graders because they are young and impressionable so they’re more likely to start loving math and science than older students. Third grade is also the first year that students perform standardized testing. The goal is to get them invested in science and math so that when the standardized test comes along, it’s reflected on their test scores.

The trainers make a great effort to ensure every student is involved and really connecting with the subject matter. Every student has a voice, and they validate the fact that their voice is incredibly important, which often leads to deeper, more meaningful conversations.

During a classroom visit prior to the field trip, students learn about appropriate attire and practice their handshaking skills with other students so they are ready to use them with technicians and visitors once they arrive at RJG. Once at the facility, they take a tour to see running machines, molds, vacuums, plastic pellets and more.

Students also get to:

- See and touch pieces from the inside of an injection molding machine such as a screw, samples of plastic and the mold

- Solve math problems that tied into what they saw on the floor

- Create puzzle pieces on the machines, then build cubes out of them to see a part from pellets to completion

Related Content

-

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

-

Steps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

.png;maxWidth=300;quality=90)