GF Machining Solutions Demonstrates AM Production, EDM Cut-Off Solutions at AMUGexpo 2020

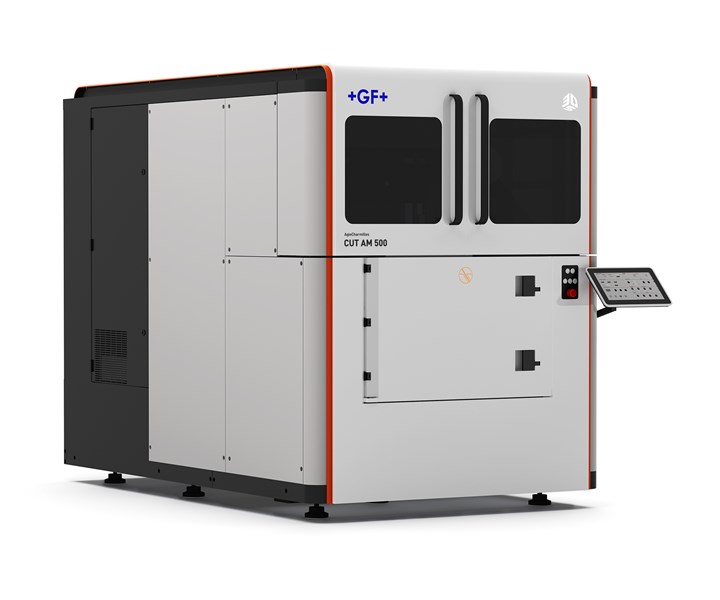

At the 2020 AMUGexpo, exhibitor and platinum sponsor GF Machining Solutions will demonstrate its high-throughput DMP Flex 350 metal 3D printer and its AgieCharmilles Cut AM 500 horizontal wire EDM March 22-26 at the Hilton Chicago.

Share

At the 2020 AMUGexpo, exhibitor and platinum sponsor GF Machining Solutions will demonstrate its high-throughput DMP Flex 350 metal 3D printer and its new AgieCharmilles Cut AM 500 horizontal wire electrical discharge machining (EDM) in Booth P1, March 22-26 at the Hilton Chicago. These high-precision machines combine to create a complete automation-ready additive process that includes the ability to quickly and accurately separate parts from build plates without the use of a band saw.

The DMP Flex 350 enables efficient 24/7 production of very dense, pure metal parts from 11 ready-to-run challenging alloys, including thoroughly qualified Inconel, titanium, cobalt chrome, aluminum and steel. Improved gas flow technology produces more-uniform part quality throughout the build area. Short changeover times and streamlined 3DXpert all-in-one parametric software speed the process from 3D model to successful part printing, with reduced assembly steps for better manufacturing efficiency and maximum uptime through well-developed and tested print settings.

The DMP Flex 350 generates precise parts and guarantees excellent microstructure density, stable mechanical properties and consistent powder quality for high-quality parts. For the ultimate in flexibility, the DMP Flex 350 upgrades to the DMP Factory 350, with integrated powder management system, high-performance sieving and automated powder conveyance. The AgieCharmilles Cut AM 500 cuts AM parts that feature specific support structures and cavities with remaining AM powder.

Related Content

-

Mold Design Tricks, Additive Manufacturing Treats & More: MMT's Top-Viewed Articles in October

October held some tricks but mostly treats for MoldMaking Technology’s audience.

-

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.