Tech Trends: Software Selections

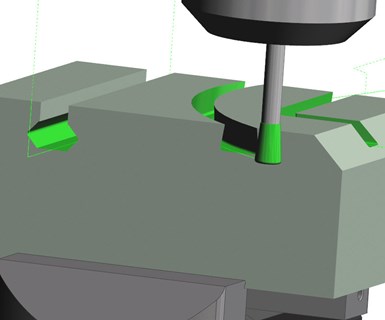

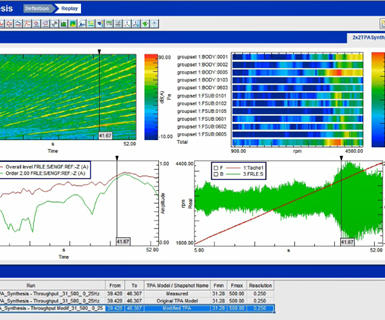

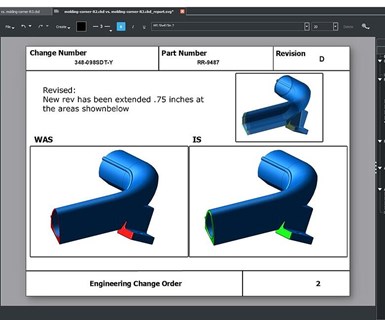

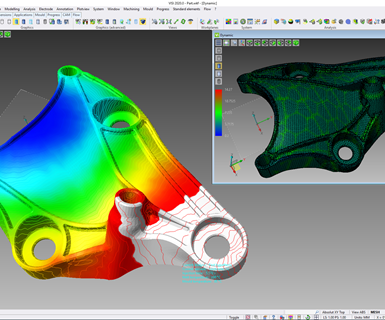

Take a glance at latest software releases and product updates from MoldMaking Technology suppliers, such as SURFCAM from Hexagon Manufacturing Intelligence’s Production Software, Siemens Digital Industries Software and Kubotek3D.

Design and engineering is essential to building a better and more cost-effective mold with shorter leadtimes. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming, so why not take a glance at some of the latest product offerings from some of MoldMaking Technology’s supplier companies? From giving greater flexibility to processes, access to technical guides and application-based materials, to updates and releases that focus on specific needs for machinist programmers, these selections offer a wide range of solutions to benefit your machining!

Interested in More?

Keep in the know about recent mold manufacturing updates with a review of recent products and services announcements from MoldMaking Technology’s comprehensive list of supplier companies.

Browse our entire database of moldmaking products in the products section, or check out our Software Zone Index. You can browse to stay updated on the latest product offerings, or search for specific product information based on categories.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

Read MoreWhat is Scientific Maintenance? Part 3

Part three of this three-part series explains how to use maintenance data, set targets and goals for improvement, and allow better, faster, and more accurate mold and part troubleshooting.

Read MoreTake Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More