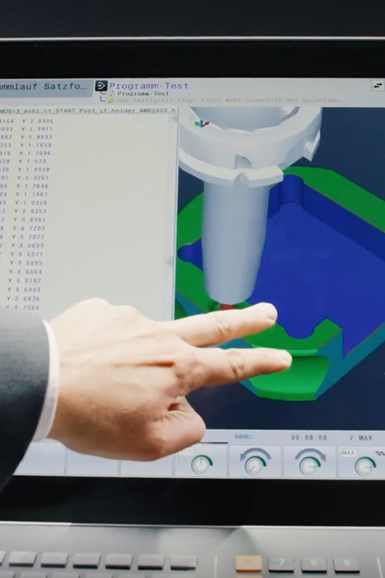

Many mold builders choose high-speed cutting over EDM nowadays because CNCs are able to meet the required tolerances and finishes. The control is key to this. Photo Credit: Heidenhain Corp.

Here is a breakdown of six features and functions to look for in a control to take full advantage of machining capability and deliver precise, well-finished molds.

- Spatial plane function: Many mold cores or bases require five-sided machining without excessive coordinated movements. The CNC should have a spatial plane function that allows the machinist to set the plane that is machined on each side of the part. That way, the machinist can program each side of the part in an X-Y-Z plane without changing the CAM program and ultimately improve the tolerances between features on each side.

- Contour deviation monitoring: The control directs axis movements to follow the 3D surfaces within predefined tolerance bands that consist of simple line segments. The control should automatically smooth the block transitions while the tool moves continuously on the workpiece surface. An internal function that monitors the contour deviations controls automatic smoothing, enabling the user to define the maximum-allowed contour deviation. The machine tool builder determines the default value in a machine parameter of the control (typically 0.01 to 0.02 millimeter). The tolerance also affects the traverse paths on programmed circular motions, which is important if the core or cavity has cylindrical details that a user machines with either an interpolation milling or a mill-turn function.

- Linear encoder compatibility: The CNC control should ensure that all machine axes follow the exact path when moving from X-plus to X-minus and then moving from X-minus to X-plus after a stepover. There must be an exact reproduction of adjacent paths after cutting direction reversal.

- Vibration mitigation: A machine axis moving very fast and changing direction on a point or using a higher-than-permitted feed rate for the cutting tool can generate vibration, impacting part quality. The CNC control should monitor any tool vibration caused by either high dynamic movements or higher-than-permitted feed rates, and then adjust feeds and speeds to avoid chatter marks on the final part.

- Operator flexibility: The CNC interface should optimize the machine dynamics based on each part’s feature priorities. The control should allow the operator or programmer to verify and optimize the program on the fly. For example, several different components made on the same machine, each with different accuracy, surface finish and lead time requirements.

- Automatic feed and speed adjustments: Milling through mold cores or cavities with variable workpiece thicknesses is another machining challenge. A solution is a CNC that can detect how much material is currently cut, so the feeds and speeds can be automatically adjusted without operator intervention. This is accomplished with sensors connected to the CNC that measure spindle load and vibration and then identify and adjust speeds and feeds within milliseconds. This technology ensures that the machine maximizes chip removal rate based on workpiece cutting tool engagement, as well as cutter and spindle life.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

How to Improve Mold Machining with the Right Control Functions

Fine tune machine setup, minimize forces and deviations, improve accuracy, and manage automation with proper control.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)