Inspection Services Help Moldmaker Push the Envelope

“As technology moves forward, to be able to design and produce these parts you must be able to prove to the customer, through your inspection results, that they will work.”

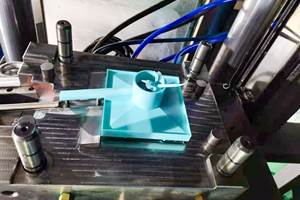

Less than four inches long, the item Gary Johansson holds looks as if it might be the clip of a pen or a piece broken from a plastic model. In reality, it is the cartridge for a surgical stapler small enough to suture veins. “Let other companies make coasters and Frisbees,” Johansson says. “We take on projects others say can’t be done. That’s a testament to our capabilities, new machines and talented people.”

Johansson is Vice President, Quality for Matrix Tooling Inc. in Wood Dale, IL. Matrix bills itself as a “one-stop shop” – services include mold design, precision moldmaking, close-tolerance injection molding, micromolding, overmolding and specialty tooling. The facility even has a clean room (a necessity, considering that about 70 percent of Matrix’s business is in the medical arena.) However, what really sets Matrix apart is the company’s extensive inspection and testing capability.

“It’s unusual for a shop our size (about 50 employees) to have the inspection capability that we have,” Johansson says. “Our customers like the fact that they can come in with a concept, or a piece part print, and all the work needed to make that piece a reality is under one roof.”

The company views its inspection capabilities as key to attracting highly technical jobs. “The envelope keeps getting pushed—thinner wall stock, for instance,” he says. “Inspection is not always about finding our mistakes, or finding the designer’s mistakes; sometimes it’s about finding a way to make things work. We use it to troubleshoot projects in-process. The inspection work we do actually helps change the production path—we can make design or material changes to make sure the project ends up where we want it to be.”

Matrix was started in 1978 with seven employees; today, the company operates in a 30,000 square-foot facility running three shifts, five days a week. They also do “lights out” machining with EDMs and machining centers. Company ownership constantly invests in new technology; their most recent purchase is a 3D printer.

That commitment to technology helps Matrix build business, Johansson says. “We have a CSS machine— a cross-section scanner (a patented inspection technology by CGI of Eden Prairie, MN)—on the floor, and we’re looking to purchase a CT (Computed Tomography) scanner,” he explains. “The CSS machine is fantastic, but it is limited to plastic. A CT scanner works with mass—that would allow us to scan, for instance, a stainless steel metal-injected molded part with a plastic overmold. With our CSS, we can have hard data for customers within 24 hours; with the CT scanner, we’ll be able to condense that time much further.”

Rapid feedback is something that sets Matrix apart, says Johansson. “We combined a mini-DVD player with a 3D stereoscope so when a part comes off the press—while it’s literally still warm in our hands—we can make movies, take snapshots, and (using a web interface like Glance or Go-To-Meeting) we can talk on the phone with customers as they view their part under the microscope.”

While Matrix strives to provide a full range of services, customers are free to choose which they want. “We’ll build a tool and ship it; we’ll build a tool and certify it; we’ll do bridge molding. We also do inspections for other companies – they send us the plastic parts and we do the inspection. That’s an entirely separate business opportunity,” Johansson says.

“As technology moves forward, to be able to design and produce these parts you must be able to prove to the customer, through your inspection results, that they will work,” he says. “When we’re able to do something cutting edge, it’s very rewarding. Our parts allow doctors to perform beating heart surgeries—they can do the suturing in seconds, rather than 20 minutes. To be part of that is really cool.”

Related Content

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreIMTS Showcases Software, Additive Manufacturing, Inspection and Measurement Tools for Moldmakers

MoldMaking Technology previews a selection of the software, additive manufacturing, inspection and measurement tools that will be present at IMTS.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)