Many manufacturers are turning to robotics to enhance their operations. Robots can often execute manufacturing and logistical tasks more accurately than manual methods. Labor shortages are another reason an increasing number of companies are turning to robotics. Many manufacturers have found that robots often don't replace manual laborers; automation enables people to get more done. Robots also handle hazardous tasks, keeping the workplace safer for employees.

The main hurdle to automation is knowing where to begin. It's critical to identify the scope of your operation and narrow down the opportunities, then prioritize the potential gains of each.

Initial Questions to Ask

When assessing where to begin with automation, your team should discuss the key aspects of your current process and workload, and answer the following questions:

- Bottlenecks are an essential consideration when assessing whether to invest in robotics and artificial intelligence (AI). For example, what are the tasks that take the longest amount of time? Could technology reduce that time?

- Another crucial aspect is the nature of the job to be done. Is the task highly repetitive? If so, it is probably a good prospect for robotic automation. On the other hand, if the task is different every time, then a robot may not be a good fit and could be more costly to implement. However, AI could still assist people in getting even these kinds of jobs done more efficiently.

- As is always the case when making any business decision, the critical question of cost effectiveness must be answered. When does it make sense to invest in automation from an economic standpoint?

Many manufacturers have found that robots often don't replace manual laborers; automation enables people to get more done.

Processes to Consider First

Evaluate your shop’s entire process and capabilities to identify areas that can benefit from automation. For example:

- Infeed: One of the most overlooked areas of automation is material infeed, which generally includes a repetitive and low-variation process to bring materials and components to the work area. Typically, being a low-variation task, this area is where automation can be highly efficient and cost effective. The infeed process can often be the fastest path to tangible production increases.

- Quality Control: Vision robots are armed with industrial cameras to provide exceptional flexibility in a variable environment. In moldmaking, inspecting mold components and parts tends to be a highly tedious and repetitive task. Its importance, however, cannot be ignored. Many vision technologies and solutions exist in the market today, which are more than capable of performing quality inspections, which enhance the working environment and increase product quality levels.

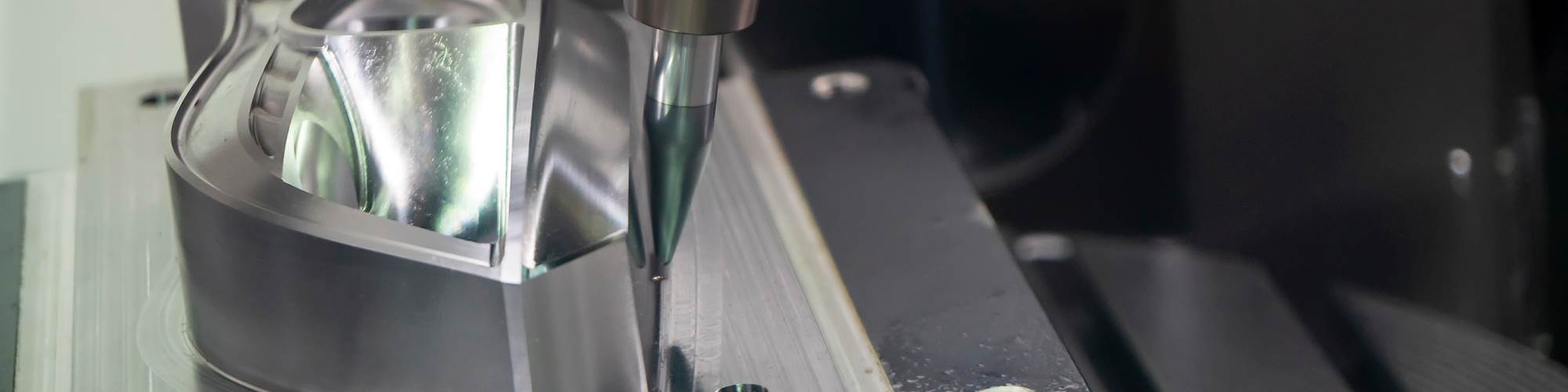

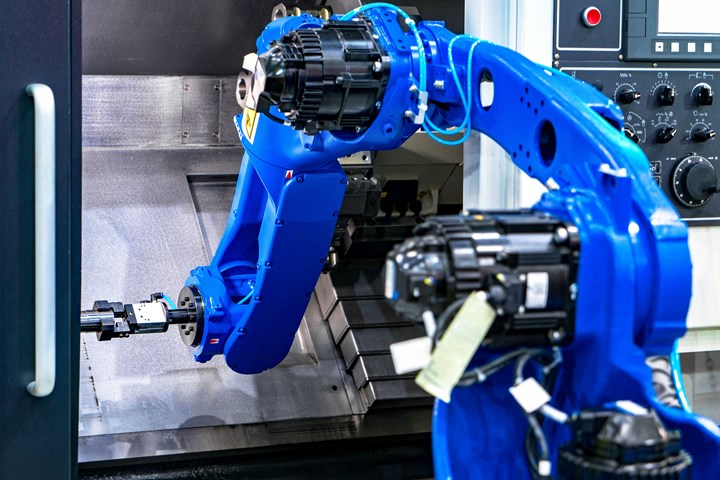

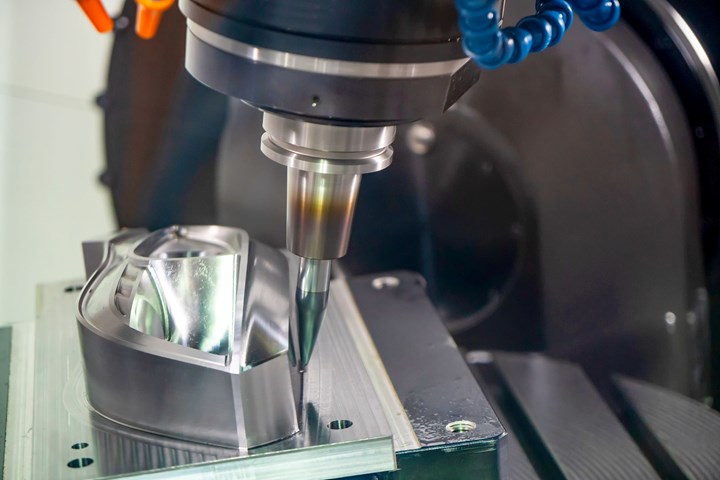

- Machine Tending: CNC machines are an effective area to integrate machine-tending robots capable of handling the loading and unloading of parts on and off the machine.

Benefits and Limitations to Evaluate

Shops sometimes invest in a robot, thinking it will be like a CNC machine. This is not true. Each has its advantages and disadvantages.

Advantages:

- Cost — A modern articulated robot arm can be considerably less expensive than most CNC machines.

- Flexibility — A robot arm can handle various geometries and make more complex shapes than most CNC machines. In general, a robot milling arm significantly increases the flexibility of milling.

- Floor space — A robot arm typically takes up less floor space than a CNC machine.

- Cuts from below — The articulated robot arm can reach underneath a workpiece and make cuts from below, which is impossible for a CNC machine to do.

Disadvantages:

- Precision — An articulated robot arm cannot compete with a CNC milling machine in accuracy and precision. CNC machines are usually more accurate than robots, with tolerances that go down to fractions of a micron. Robot arms can typically achieve accuracies in the hundreds of microns.

- Stiffness — CNC machines usually have very high degrees of stiffness in three axes. However, the stiffness of the robot arm will vary. And it’s possible to have higher stiffness in one axis than another with a robot.

- Ability to work with very hard materials — Hardened steel is needed for molds that last a million shots. However, because the robot arm has less stiffness, it can’t handle materials that are as hard as CNC machines can.

Meanwhile, buying an articulated robot arm can do much more than milling. Other tasks in your operation may be suitable for a robot arm to perform. For example, the arm could be used for sanding, painting, picking and placing, palletizing and more.

Buying Options to Review

The need for automation technology continues to grow and the options for small-, medium- and large-sized businesses have increased. However, the initial investment is often a valid concern and has been a significant barrier to entry to robotics for many shops. The common misconception is that it must be implemented as the newest and most top-of-the-line technology. On the contrary, the benefit of automation becoming a widespread part of many manufacturing processes is that a large secondary market for quality robot solutions drives down prices.

Also, in the case of infeed and end-of-line solutions, a vast selection of standardized options can help. Finally, to alleviate the sticker shock of purchasing a new robot solution, look for robot leasing programs that can break down the cost of a robot into extremely manageable monthly payments.

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

5 Reasons to Consider Automation

As ongoing advances enable machines and humans to get better at talking to each other, eventually more shops will become more automated. If your shop hasn’t yet looked into upping its automation game, here are five reasons why you should.

Read MoreHighly-Automated Tool Shop Achieves Efficient, Precise Medical Device Manufacturing

When a basketball player needs a knee replacement, standard implants simply won’t do. With a total of 18 different additive manufacturing systems, the Aesculap division of medical company B. Braun is the place to go to have custom implants printed to size. However, the highly-automated tool and mold shop has much more to offer when it comes to producing injection molds, complex progressive dies as well as prototypes and fixtures for series production.

Read MoreHow to Cut Mold Machining Costs in Half

How to hard mill and finish grind in a single setup, including an in-machine probing inspection.

Read More

.png;maxWidth=300;quality=90)