It's a classic manufacturing startup story. A little entrepreneurial spirit and a dose of technical expertise in a specific area provide the foundation for a new company launch offering a unique twist on current technology. This time that technology is TrueShape™ 3D printing, and the company is Mantle Inc.

Why should you care? Because their focus is additive tooling produced in a system that extrudes a metal paste, yielding a part (in this case a mold insert) with the surface finish and tolerances worthy of tooling, and all at a lower price point.

Mantle started five years ago with two co-founders—one who developed a metal paste for the solar industry, which he commercialized and then applied to 3D printing, and the other is a mechanical engineer with product development experience in low-volume plastic part production and moldmaking. Together they used their knowledge to develop a steel paste to print tooling.

Since the launch, they have been quietly working with a few companies to gain feedback and direction while validating the technology and building some proof cases.

"There are several aspects that make our 3D printing approach new, but basically we print layers and then with high-speed cutters we refine the shape to give the required accuracy and add any necessary details," says Paul DiLaura, Chief Commercial Officer for Mantle.

Mantle's 3D printing approach has two target applications: to accelerate launch to production with production tooling and to compress product development cycles using real production materials.

He describes the three main steps:

- The 3D printer extrudes a paste (less dense than toothpaste) that consists of metal particles and liquid carriers that push the metal particles together—like metal dust inside a liquid. The printer deposits the paste layer by layer in the shape of the mold CAD file.

- The system then dries the paste, removing the liquid components to begin the densification of the metal particles as they settle together. Next, while in the same machine, the part is shaped using high-speed CNC cutting to achieve the necessary accuracy and surface finish.

- After the printing and shaping steps occur, the part is transferred into a high-temperature furnace and is sintered into a fully dense metal part.

"We raise the temperature to just below the melting point of the material, which is where the final densification of the metal particles occurs, and the final mechanical properties are set. The final part is a hardened tool steel that performs just like a P20 or H13 steel, in that you can machine, EDM, and weld them. They come out of our process with a surface finish that is suitable for molding," DiLaura says.

He says that you can't tell the difference between their printed insert and a traditionally built insert. "Ours performs just like it and even better in terms of abrasion and corrosion resistance," DiLaura says.

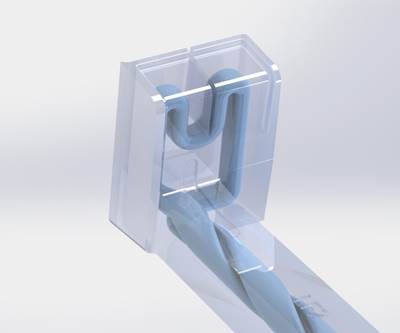

Recent case studies have offered up results Mantle can now share. For example, the insert in the photo above was produced with Mantle's printing process and yielded a surface finish of about two micron RA, comparable to EDM. "Standard tolerances are within 100-micron across a four-inch part," DiLaura says.

Another example is an insert for a dishwasher component for a major appliance OEM. "After the customer did some characterization of the materials and got comfortable with the process, we printed the insert that drops inside a four-cavity tool alongside the other three conventionally made inserts," DiLaura says.

The Mantle insert did not require any post-processing so the customer could just drop it directly into the mold, which ran for 200,000 shots as part of a production run. Then as part of a regular maintenance cycle, they took the inserts out for inspection and found that the wear was comparable to that of the conventionally made inserts.

"The value of our process is cost and lead time. We printed the insert in two days versus the 7 or 8 days it took the customer previously," DiLaura says. "Part of the reason for the cost savings is the required post-processing that our process does not require. The cost of other printing systems focused on tooling applications plus the necessary post-processing makes them more expensive than our process." That's because Mantle's system does not rely on lasers.

DiLaura shared that another customer who typically cuts a prototype tool, which takes seven weeks, asked Mantle to step in and use their process, which only took eight days to print the cavity and core that fit inside a standard mold base.

Mantle is targeting OEMs and major suppliers who have design responsibility for the parts, which in some cases, have vertical integration with molding and moldmaking; molders with varying degrees of moldmaking and maintenance capabilities; and moldmakers who have all the machining capabilities allowing them to compress the time it takes to get molds back to their customers. As a result, moldmakers can engage much earlier in the product development process with their customers. This strategy allows them to provide quick-turn quality parts, bridge tooling and then ramp-up to the production business.

Mantle's approach targets two use cases: (1) accelerating launches with production tooling and (2) compressing product development cycles with high-quality prototype tooling that can bridge into production.

"We're going to be deploying our first printers at the end of this year. Up until now, we've been printing all the parts and inserts and sending them to people,” DiLaura says. “Customers will be able to use our additive technology to make tooling for a wide range of their high-volume end-use parts.”

When I asked DiLaura the most significant limitation of this technology, he noted that it is the reluctance to embrace something new and the need for validation. "A lot of data is needed to get people comfortable and to build confidence and trust in the industry," DiLaura says. And that is precisely what they are committed to doing.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreRead Next

ICYMI, MMT Chats: The Need for Broader Additive Manufacturing Education to Understand its True ROI, Part 1

MMT Chats invites the additive manufacturing (AM) team from Action Mold and Machining in Grand Rapids, Michigan, to share their passion for and experience with additive manufacturing in moldmaking by exploring how education matters to fully grasp AM’s return on investment. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreSelling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

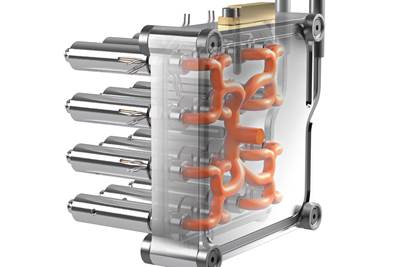

Read MoreGiving Mold Builders Additive Capabilities, Super Creativity

I saw my first 3D-printed hot runner manifold at K 2019 in Germany, but the system did not have a name yet. Fast forward to 2020 and it not only has a name, but it’s been successfully implemented in a number of applications across Europe. And today, it’s ready for the North American marketplace.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)