Getting to Market with Rapid Cut Tooling

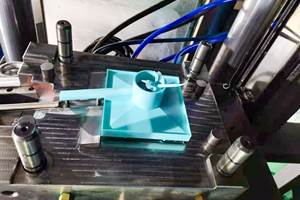

Companies needing injection-molded components are using rapid cut tooling (RCT) to meet the challenges of the marketplace.

Share

In today's dynamic business environment, getting to market first is critical. The speed at which products are developed and introduced is clearly linked to profitability and market share. Knowing this, it is not surprising that companies needing injection-molded components are using rapid cut tooling to meet the challenges of the marketplace. Rapid cut tooling (RCT) allows companies to field test and produce sellable product for product launch or low-volume production - in half the leadtimes associated with traditional tooling techniques.

To begin, let's define what a rapid cut tool is. RCT, by definition, uses machining as the main tool build process; it does not rely on casting or sintering technologies. From mold base to final tool assembly, rapid cut tooling uses the same equipment used in constructing production injection molds. Mold bases are machined, cavity and core work is done on a CNC mill and part features are EDM burned into the tool. These molds are welded, textured, gated and ejected like production tooling. An advantage of matching the production tooling process is that the rapid cut tool performs similar to production tooling. It becomes easier for buyers and engineers to set expectations around part quality, tool life and even pricing since there is a long history to draw from.

Rapid Cut Tooling Options

Rapid cut tooling comes in several forms. Typically, this tooling is either one or two cavities. RCT is made from either aluminum or steel. There are both softer and harder materials used on occasion, but QC-7 aluminum and P20 steel make up a majority of such tooling. A unique option of RCT is the use of either manually pulled tooling inserts or automated slides/lifters. Manually pulled inserts simplify the tool, making it faster and cheaper to construct when compared to automated tooling. By having options, you are able to select and construct tooling that best meets your needs.

Performance

RCT derives much of its value from the speed at which the tooling is completed. It is not unusual for RCT to be delivered in two to five weeks. This speed is impressive, but it is important to set the proper expectations around other key performance arenas.

Tool Life

Tool life can vary greatly depending on the raw material of the tool, part geometry and resin selection. Using a standard, low glass-filled resin on a part of moderate complexity, aluminum tooling typically produces 30,000 to 50,000 shots. Moving to the extremes of complexity and resin selection, aluminum RCT can produce more than 150,000 shots on the high end and fewer than 5,000 shots on the low end. For this same scenario, using P20 tooling, quantities typically range from 50,000 to 200,000 shots. Moving to the extremes, P20 RCT can produce more than 500,000 shots on the high end and fewer than 25,000 shots on the low end.

Tolerances

Whether you choose aluminum or steel, RCT tooling holds tight tolerances. The tooling is typically cut within .002 of the desired dimension. Tighter tool tolerances can be held (within .001) for critical areas. After establishing a cycle, standard tolerance for parts made from RCT is typically q.003. As with production tools, part geometry and resin selection play an important role in determining final tolerances. If a tool is constructed with a manually pulled insert (not automated), a dimension may be difficult to control due to the cycle variance associated with the manual operation of the insert. It is important to discuss any critical dimensions with a tooling source prior to a tool build.

Resin Specifications

If specified resin is necessary for testing and product introduction, RCT is an excellent option. Any thermoplastic can be molded in RCT with glass- and carbon-filled materials commonly being specified. Resins requiring a mold temperature of more than 300 degrees will decrease the performance of aluminum rapid cut tools.

Cost and Delivery

Aluminum RCT tools are 60 to 80 percent the cost of a single-cavity production tool with leadtimes typically half that of standard production tooling. Steel RCT tools are 80 to 100 percent the cost of a single cavity production tool with leadtimes typically half that of standard production tooling.

When to Choose RCT

As with any technology, you need to know when to use rapid cut tooling. This requires not only an understanding of the technology's performance characteristics, but also an understanding of how the technology fits into your project. Following are some questions that help to determine if this technology is the best solution for your project.

Does RCT significantly reduce my risk of missing a critical deadline?

With speed being critical during product development, it is wise to fully assess the risk and ramifications of not meeting the scheduled delivery.

What happens if I am early with this project?

Opportunities (profit, improved customer relationships, competitive advantage, image, etc.) created by an early delivery can justify the use of rapid cut tooling. Know whether the components being considered for RCT are on the critical path. If they are not, you may want to concentrate on those components that are on the critical path.

What is the expected part quantity for the life of the project?

This will help determine if RCT can be used for testing, bridge to production quantities or for the entire production run.

What is my budget?

Know the resources available for the project and when they are available. If needed, additional monies should be allocated to a project if RCT can create opportunity and increase value delivered to a customer.

What confidence level do I have in the design?

If engineering changes are expected, evaluate the cost and timing impact when applied to different tooling technologies. RCT increases in value as design confidence decreases.

What quality standards must be met for this project?

Know the cosmetic specifications, tolerances and inspections needed. This alone may dictate which RCT option, if any, to use on a project.

What type of testing do I need and when must it be done?

RCT is an excellent choice if speed and part quality are needed for testing. Also, RCT allows for extensive testing since it has a longer tool life than other technologies used in the prototype phase. If using specified resin or holding tolerances are not critical, investigate and compare other tooling options.

Picking a Supplier

Having the right supplier leading your RCT efforts is as equally important as verifying that RCT is the right manufacturing technology for a project. As in all industries, there is a wide range of performance levels and expertise among RCT suppliers. If you plan on repeatedly using RCT as a strategic element of your product development process, I recommend strategically selecting a supplier. Just like a family practitioner may be able to handle an emergency room situation, we all would prefer to have a trained ER doctor on the scene. The ER specialist not only has the skills to do the job, but also possesses the sense of urgency, training, experience and communications needed in such a setting. So it is with RCT suppliers. Many companies have the machines and toolmakers to build rapid cut tools, but not everyone is trained in the field.

Here are a few questions that will help you choose among RCT suppliers:

What is the supplier's core competency?

Look for an extensive tooling and molding background.

What is the supplier's experience?

Find out the number of tools the supplier has built and the time it took to build them. Get specifics. Have they done work like your project? Are they familiar with your industry standards?

What percentage of their business is RCT?

This is important if you need a stable supplier for both current and future projects. As workloads vary, a supplier whose business is focused in other arenas may take on a rapid cut tool one time, but may be less willing to do so the next time.

What is the supplier's capacity?

Match your capacity needs to that of the supplier. Consider both tooling and molding when evaluating capacity.

How does the supplier handle project management?

Communications, response and knowledgeable people reduce frustrations and leadtimes. Understand how a supplier handles these details.

What are the quality standards of the organization?

ISO and QS are well known. But, if they are not certified, look to see if any advanced quality planning is done. Investigate the supplier's inspection process - when, where and how are parts verified?

Do they offer any value-added services that make your job easier?

Many RCT suppliers offer additional services that reduce your project management time.

Summary

The above questions seem logical. Most people sourcing work want to ask them. But the reality of time constraints or miscommunications has caused more then a few failed customer/supplier relationships. It is very important to know what you expect from a supplier and then investigate a potential supplier to confirm that it can meet your expectations.

Whether used for testing, bridge-to-production or low-volume production, rapid cut tooling delivers great value to those organizations that need to develop and introduce products quickly. This value is driven by a rapid cut tool's unique blend of speed and quality. Understanding when and how to use such tooling along with good supplier selection, allows for fast market entry with maximized profits.

Related Content

Variable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreAdvancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)