Preferred Tool added Jingdiao’s automation system (above, on right), which holds 110 pieces of graphite and just-cut electrodes — enough for four days of unattended machining, as the team discovered last fall after loading the machine before departing for IMTS. They returned to find that the machine had completed enough electrodes to burn for 200 hours. Photo Credit: Jingdiao North America Inc.

Owned by Sharron and Paul Peltier, Preferred Tool of Hugo, Minnesota, is a full-service mold builder producing roughly 175 new molds/year with a team of 24 operating from 18,000 square feet/1,672 square meters of space. Customers hail from the medical, defense, firearms, automotive, appliance, recreational vehicle, fiber optic and electrical industries.

The company specializes in steel tooling for straight plastic injection, gas-assist, 2K/overmolding, rotary and micro molding, plus steel metal injection molding (MIM). Both plastic and MIM molds typically have two to four cavities, often with significant complexity/side action, although the team also produces some prototype/low-volume aluminum tooling. Preferred’s manufacturing sweet spot is mold bases sized between 4 × 6 to 24 × 36 inches/102 × 152 to 610 × 914 millimeters.

Preferred Tool co-owner Paul Peltier (left) and toolmaker Mike Miller (right) are looking at an electrode cut in the five-axis graphite mill from Jingdiao to ensure it has all the detail needed for one burn in the cavity. Photo credit: Jingdio.

Even before the pandemic, Preferred had demonstrated it was competitive in terms of cost and timing with offshore moldmakers. That’s partly due to the size of the molds the company produces and the fact that it keeps significant stock on hand — much of it hardened steel.

It’s also because Paul Peltier’s philosophy can be summed up as: “To build the best quality tools, you need the best quality equipment.” The team works hard to stay current on the latest technology, replacing older equipment with new purchases several times per year.

Productivity Improvement Needed

A good example of how upgrading technology can impact productivity occurred last year. During the pandemic, work never slowed for Preferred, and the company experienced some of its busiest and most profitable years ever.

Preferred Tool owns 10 EDMs — seven sinkers and three wires — and uses them daily to burn geometry into its molds, finding that approach to be faster and more accurate than machining in most cases. Photo Credit: Preferred Tool.

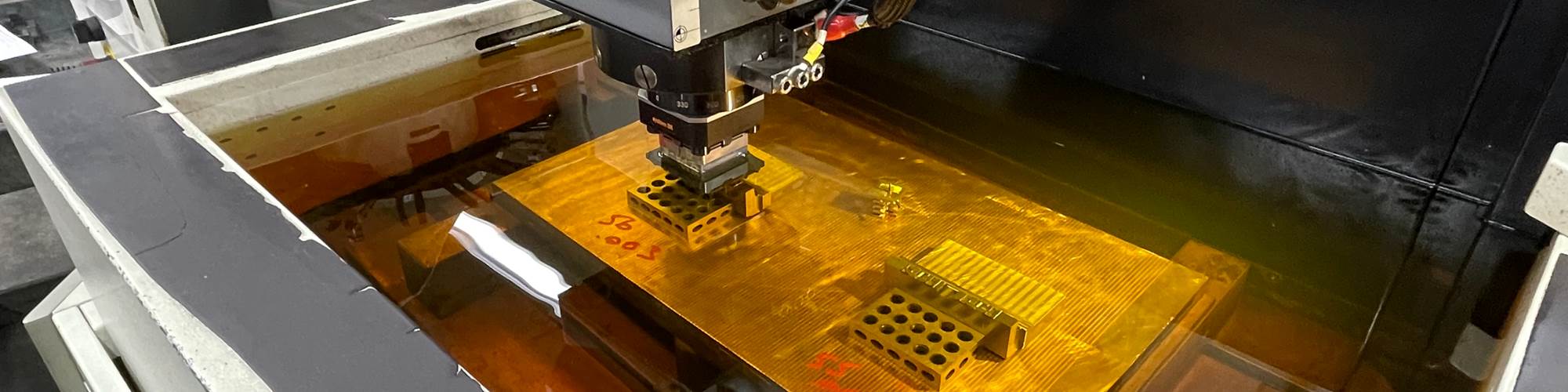

Preferred owns 10 EDMs and uses them daily to burn geometry into its molds. The company had repurposed three mills — all three-axis, only one with automation, and all designed to cut metal — and was using them to mill graphite electrodes for its seven sinker EDMs.

However, the mills couldn’t keep pace with increased demand, leading to bottlenecks in electrode production that hurt productivity. Peltier started looking for a newer, faster general-purpose mill. After considering many companies and products, a discussion with long-time associate, Jeff Johnson, president of sales at AllTech Machinery and Supply Inc., led Peltier to take a different approach.

Johnson spent 18 years building tools and dies before switching to CNC machinery sales. A chance visit to a booth at the 2019 Amerimold Expo introduced him to CNC machinery OEM, Jingdiao North America, Inc., which is known for the high speed and higher tolerances of its three- and five-axis mills.

“I’ve spent my life working and selling in the ‘Rust Belt,’ and too many mold and die makers here have been burned by buying poor-quality equipment,” Johnson explains. “I first had to do my own research before I agreed to represent them. I learned there was no question that Jingdiao built really good machines, had a good reputation and took a customer-centric approach to doing business. However, I’ve learned that reputation building can be a slow process requiring a patient and methodical approach. Still, to offset high labor costs, U.S. manufacturers must leverage as much technology and automation as possible, and Jingdiao machines have lots of both.”

Preferred Tool can cut more detail on electrodes without additional setups.

Graphite Mill Offers Micron Accuracy

Founded in 1994, Jingdiao builds 12,000 mid-size CNC machines/year alone. It produces machines for high-volume industrial machining and high-speed/high-precision CNC centers for the mold/die and medical machining segments.

A large team of degreed engineers and technicians deliver and assemble machines, train customers and troubleshoot problems, plus the company commercializes five new technologies or machines annually. In addition to its China manufacturing and service facilities, Jingdiao maintains sales and service locations in Malaysia, Vietnam, Germany and the U.S.

The company not only designs and builds its own machines, but develops and produces nearly all of the equipment, software and controls used on them, including robots, automation cells, palletization systems and even CAM systems.

Toolmaker Mike Miller (left) and Programmer Peter Gross (right) inspect electrodes. Since installing the Jingdiao five-axis graphite mill, the accuracy and finish of the electrodes at Preferred Tool have improved greatly. Photo credit: Preferred Tool

“Rather than using generalists to write software or produce automation equipment for specialized uses like mold and die production, Jingdiao takes its deep knowledge of CNC machining and develops purpose-built technology that is incredibly powerful yet easy to use and fairly priced for what it offers,” explains P.J. Naughton, sales and marketing manager, Jingdiao North America Inc. “This helps us verify and maintain the high precision and consistency we’re known for because we’re not relying on other companies to do that for us.”

That integration gives Jingdiao great control over machine accuracy. For example, structural components for frames are produced via the cast-in-gauge process. Frames are reinforced in all three axes, and all machines are built in temperature-controlled factories. Jingdiao uses purpose-built machines to build other Jingdiao machines. Even the company’s cartridge-style spindles are produced in a cleanroom environment and use ceramic bearings. As company engineers and technicians assemble new CNC centers at customers, they laser align each machine to within 2 microns of accuracy; afterward, the machine can repeatedly hold that tolerance to <1.8 microns.

“Because of the thermal stability of our machines, our double-layer insulation system that keeps high operating temperatures from affecting the workpiece and our own spindle and chiller technologies, moldmakers don’t have to hand polish tools anymore,” Naughton continues. “They can achieve a mirror finish, even after 50 hours of machining, because stepover on our mills is so precise and we control thermals so well that we don’t overheat the machine. Our chilling fluids can hold temperatures to ±0.5°C.”

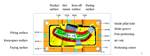

All Jingdiao precision machines are designed for automation and equipped with an integral coordinate measuring machine (CMM) probe and a five-axis auto-alignment feature. If a workpiece is misaligned by even a degree on the cutting table, the machine adjusts programming to compensate so the piece is cut precisely without requiring it to be reset. Jingdiao’s SurfMill CAM system automatically checks programming to ensure it won’t crash the machine even before it leaves the designer’s desk. Programmers can specify critical points on workpieces, which probes will recheck after machining. Even when SurfMill isn’t used, the machine will run its own verification routine on programming and cutting tool selections to determine if they’re likely to cause a spindle crash.

Productivity has increased so much that the older graphite mills were idled and are being sold.

High-Precision, High-Speed Electrode Machining

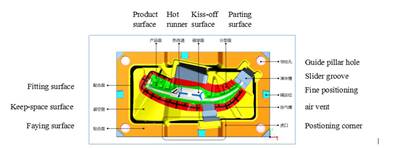

Preferred Tool purchased a five-axis GRA200 graphite mill from Jingdiao that was installed in April 2022. All Jingdiao graphite machines run at high spindle speeds of 32,000 rpm, as graphite is brittle, not hard, and high-speed machining produces better results with small cutting tools. They feature a heavy cover, powerful vacuum systems with constant air pressure and extra shielding and sealing to keep dust out of critical subcomponents, such as ball screws, spindles and guideways.

Preferred Tool's Paul Peltier (top, right) and Josh Rosenow (bottom, right) verify dimensions with a CMM to ensure the accuracy of the EDM process. Electrodes can also be inspected on the five-axis graphite mill with the same results as a CMM. Photo Credit: Jingdiao North America Inc.

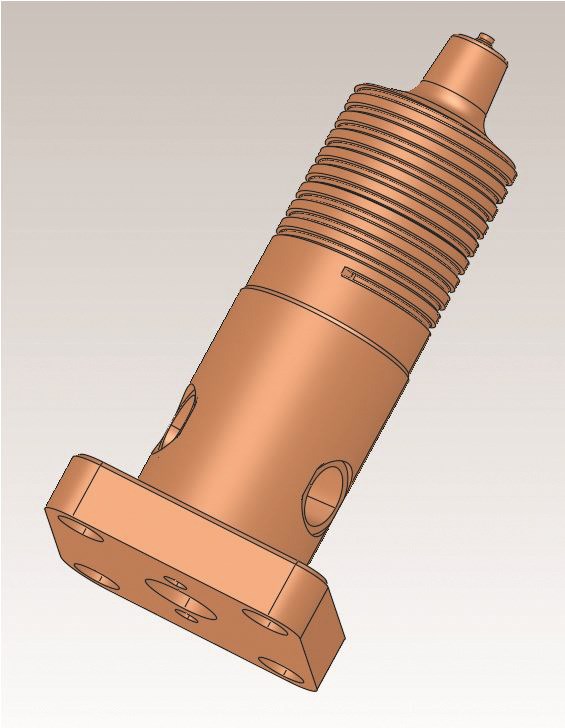

A good example of what Preferred can now do with its purpose-built graphite mill is a large tooling package it produced last spring for a medical device manufacturer, which commended Preferred for the fastest turnaround time on tooling the OEM had ever seen. A particularly challenging threaded core in H13 on one tool had its entire internal thread EDM’d. “Our electrodes handled that task perfectly,” Peltier recalls. “If we’d had to send that out to be ground, it would have taken far longer and cost far more.”

The machine has a 7.87-inch/200-millimeter table and is a true five-axis, not a 3+2 center. That enables Preferred to cut more detail on electrodes without additional setups. In turn, that reduces graphite cutting time and workpiece burning time and saves material since fewer electrodes are needed per job. Productivity has increased so much that the older graphite mills were idled and are being sold.

With nearly a year’s experience under his belt, would he do anything differently? “I was a little nervous about using five-axis when I started out, but the next metal mill I buy will be five-axis from Jingdiao,” Peltier adds. “Also, we didn’t realize at the time how powerful Jingdiao’s software was, but we’re really glad we purchased it. I can’t say enough good things about the people at Jingdiao, and we look forward to doing a lot more business with them.”

One of the most challenging pieces in that package was a threaded core insert (shown above). All threads were produced by burning with electrodes. Photo Credit: Preferred Tool.

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreRead Next

Defining What Makes High-Speed Machining Different

A look at what true high speed and true high precision can produce, as well as what makes high-speed machining different from traditional milling.

Read MoreHow to Machine Micron-Level Precision Molds in One Try

On-machine measurement intelligence and modification technology helps mold builders overcome machining variables and quickly produce micron-level tolerances.

Read MoreOn-Machine In-Process Inspection Improves Machining Accuracy

High-speed machining with on-machine in-process inspection, machining management, and control technology reduces machining time and eliminates manual bench work.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)