Extensive CAD/CAM Functionality Helps Complete Medical Mold Build in 6 Weeks

The industry has been talking a lot about automotive lately, so I thought I’d switch things up a bit and share the success of a medical device mold project attributed mainly to the right CAD/CAM with built-in mold component supplier catalogs.

Most people have an emotional response to the making of a potentially life-saving medical device because at some point in their lives a loved one may use or depend upon one. That is true for the RBR LegflowTMdevice that reduces the possibility of deep vein thrombosis (DVT) by providing a way for a patient to perform three simple foot exercises that lead to an 11-fold increase in blood flow to the lower limbs.

The company responsible for this device is RBR ActiveTM , and they turned to UK moldmaker/molder Fenton Precision Engineering to design and build a 30-component P20 mold using VISI and a Dugard CNC machine programmed with WorkNC (both software from Hexagon Manufacturing Intelligence).

Hexagon shares its story with this project:

RBR ActiveTM Managing Director Paul Westerman approached Fenton to produce a mold for an overmold concept, but Fenton Technical Director Richard Brown recommended to mold it as a one-piece product instead.

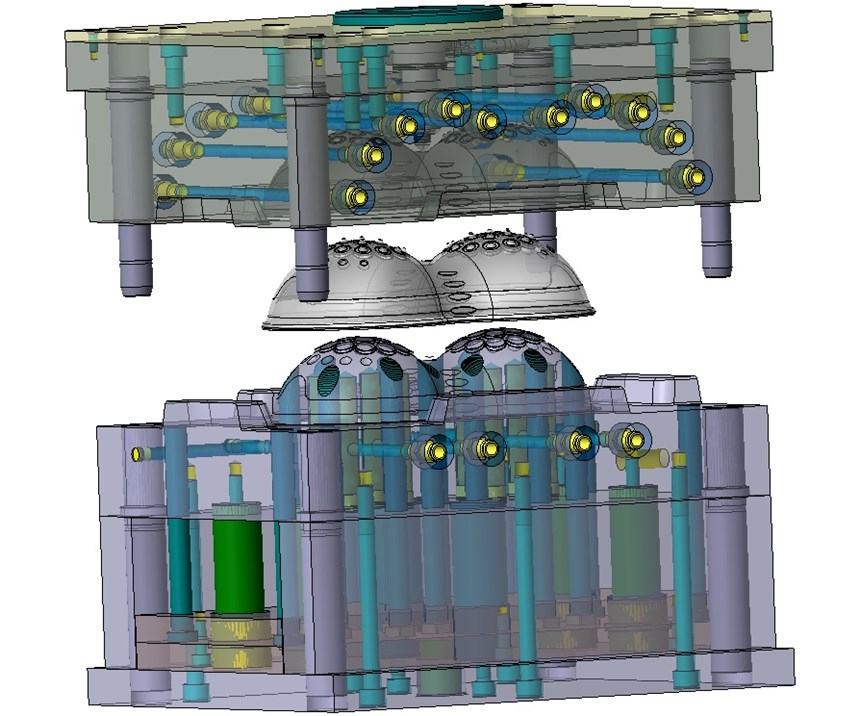

He says the mold was “straight open and close” with two cavity plates, support plates, and back plates, comprising around 30 different components. However, he also noted that the main design challenge was ensuring that there were no side actions or lifters.

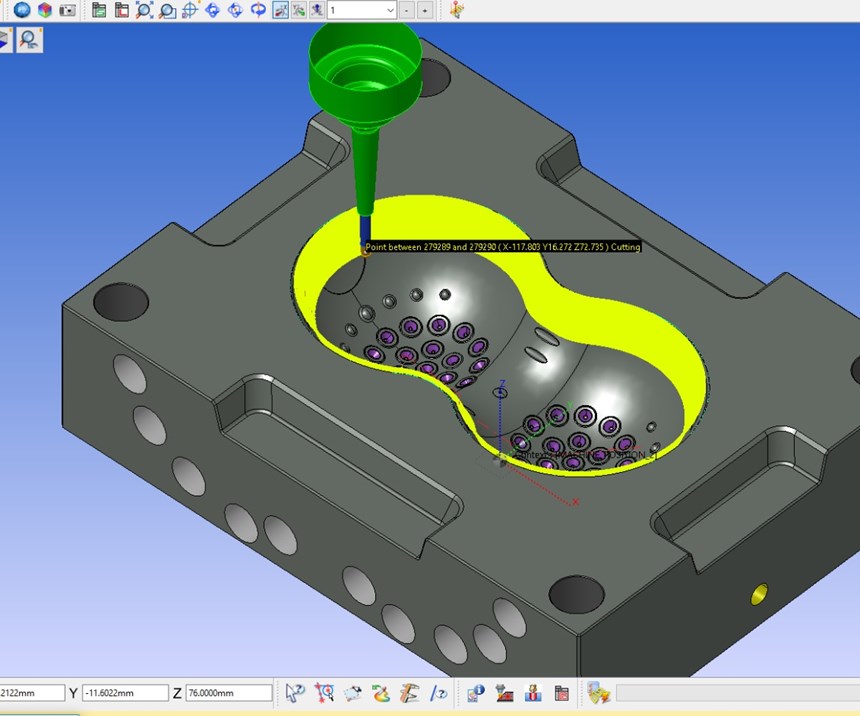

The wall section at the top of product’s two dome structures, which contain 38 nodules, had to be particularly thin to allow flexibility. “However, there is a limit as to how thin we could make the wall.” Brown says. They got the optimum thickness through VISI Flow Lite, which simulates the filling phase of the injection molding process, and Design Engineer Martin Edwards defined all the initial molding criteria and gating positions. This helped the shop achieve a well-balanced filling of the cavities under optimum manufacturing conditions. Next they built the mold using VISI Mold with its built-in Meusburger catalog for native parts.

The complete mold build took around six weeks. The cores and cavities were machined through WORKNC, with each plate taking around 25 hours, and another 20 hours for the build.

“The mold required complex machining with a lot of small solid carbide cutters from a variety of suppliers. We also used shrink-fit tooling to ensure grater accuracy, balanced chip loads, better finishes, and increased speed and feed rates,” Brown says. And, he notes that WORKNC’s ability to produce high-quality surface finishing kept any additional polishing to a minimum.

While the extensive range of functionality in both VISI and WORKNC combined to ensure the project was completed successfully, Brown says VISI’s mold package and its built-in catalogs of mold component suppliers, such as Meusburger and HASCO, were critical at the design stage, while WORKNC’s surface finishing and its ability to program small cutters with precise, flawless, toolpaths, were critical to the manufacturing.

Fenton designs all of its molds in VISI and machines them on one of the shops six three-axis Dugard, Mazak and Mikron CNC mills. “WORKNC readily reads native VISI files, so it’s a seamless transition from CAD to CAM. Once we save the VISI workfile we simply open it in WORKNC.”

Fenton’s tool room and main molding facility are in Northamptonshire, with an additional molding factory in Leicestershire, where the RBR LegflowTM was dual pad printed. They have a total of 33 molding machines across both sites, having invested heavily in Yizumi injection presses, along with Negri Bossi, Arburg, Borche and Demag, ranging from 25 to 500 tons.

Related Content

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)