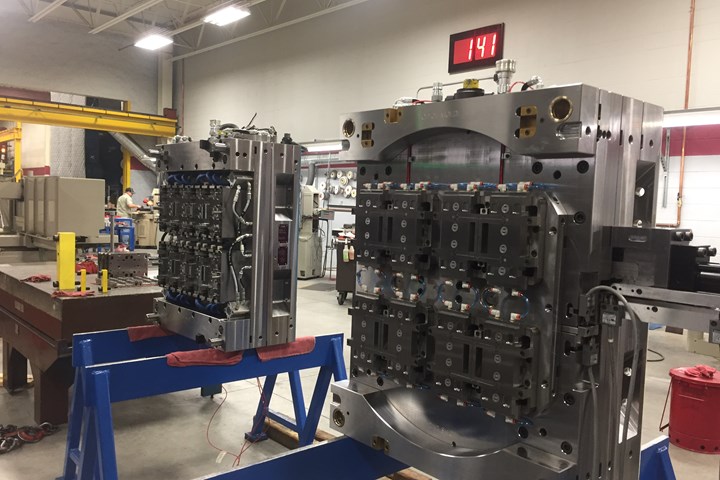

This lift-and-spin 16+16 cavity two-shot mold concept was created to allow two-shot molding techniques without a rotary platen, making it very versatile to run in multiple presses. Photo Credit: Innovation Mold & Design (IMD)

What do you view as Innovation Mold & Design's chief competitive advantage?

Alex Hermann, President, Innovation Mold & Design: We combine innovation, technology and precise craftsmanship to deliver the highest quality products the first time. Our highly skilled team, automate processes and partners/vendors relationships ensure attention to quality and workmanship. We are known for producing highly accurate, tight-tolerance tooling that requires a lot of engineering with competitive timing. This is an area where we can be competitive, even with the offshore markets.

We manufacture a wide range of tooling from single cavity prototypes to high cavitation Class 101 production molds using the latest machine tool technology and a lights-out approach. Quality assurance is met throughout the manufacturing process by our highly-skilled toolmakers. We also know that shorter production lead times are extremely valuable, so we offer in-house sampling capabilities.

What is your team philosophy?

Hermann: I have a huge banner hanging in the shop that says: "The best people create the best processes. The best processes create the best technologies. The best technologies create the best products." This means putting the right people in charge, letting go of individual responsibilities and enabling people to take on more responsibility. The way to master your craft is to have a departmentalized shop where people are specialized. If you have a CNC programmer, they need to be the best CNC programmer, etc. This approach creates an assembly line-like process with custom molds. Every tool is a little different, but if you apply the same process, you can streamline things.

This medical device two-cavity mold features multiple compound actions.

Share how Innovation has kept up with technology.

Hermann: We used to be 100% consumer products work—basically form and function with fairly wide open tolerances. However, to go to the next level and diversify into other markets, we needed to invest in talent and technology. We invested a total of $6 million since 2012—including the expansion and new equipment.

But before the technologies, it's communication and process. When we get a P.O. from a customer, the first thing that happens is we generate a timeline for the customer to approve, we provide a progress log along with the way and process check sheets in every department and a pre-ship checklist.

As far as technology, we find ways to streamline and automate, where we can to remain competitive and cost-effective within our customers' timing demands. For example, incorporating more automation and focusing on more complete turn-key solutions while working together with our customers to help them streamline their processes and profitability as well. The latest investment was introducing five-axis machining to our capabilities.

We have three automated EDM cells paired with electrode-cutting machines—one of which is five-axis—and we are starting to incorporate this on our steel-cutting side as well. We also have one cell capable of lights-out machining, and have a horizontal machine equipped with a pallet changer to help increase our unattended runtime. We are excited for our latest purchase, which is a larger Makino V80s five-axis machine with high-speed milling and finishing capabilities that will enhance our capabilities and efficiencies.

We used to write a simple program for a machine to run for hours, sometimes days. Today, with the newer machine technology, machines process information can run in half the time or faster, which allows for more capacity and requires more programming time. To keep up with this speed, we must maintain a backlog of programs to run the machines lights-out.

We also brought a lot of work that we used to outsource back in-house. For example, we outsourced 100% of our turning, wire EDM and polishing work. We purchased the necessary equipment and additional resources to bring this work in-house. This has given us control of quality as well as the schedule. It saves time, as we're not spending a day delivering a tool.

In terms of the equipment you buy, you learn the hard way that you get what you pay for. For example, one machine tool had a great price and worked right out of the box, but about a year later, it started failing. It could not hold the accuracy we needed to take on some of these new markets. If you're cutting twice, you throw your timeline out the window. We don't have the time. We have to cut once, and it has to be right. That's how competitive it has become. We are now challenged with doing a standard 16-cavity mold in eight weeks instead of the traditional 16 weeks. The key is the right process and plan, which includes automation.

This stack mold design allows greater cavitation within a smaller press platen size.

Then there is quality assurance. At Innovation, first, we buy equipment that we can trust, and that cuts consistently. Before a block leaves a machine, it is checked. That involves in-machine inspection with probes or third-party inspection. We have an in-house CMM and a vision system, and three partners on the outside for an unbiased opinion due to the tolerances we work with, especially on medical parts.

If we perform this in-house, we may consider it 'good enough' when we need to shoot for being right or wrong, and a third-party source gives us that honest answer, which helps us determine if we need to make an adjustment, replacement, or have a conversation with the customer.

We also are a paper-free environment where everyone works off the same model. It's our culture. Everyone checks their e-mail every morning for updates and then grabs a revised model, ensuring the entire team works on the most current model. Our experienced design engineers use the latest Siemens NX/Unigraphics, SolidWorks, Delcam and Mastercam CAD software to achieve accurate, efficient tooling designs and processes.

What are the most significant ways you have expanded your business in terms of your growth strategy?

Hermann: We continually look to add to our customer base and the markets we serve to be diversified in the areas where we perform best. This approach helps us maintain consistency as some markets slow, and others rise. We have made great strides in the medical and military industries and wish to grow within those markets and our current key markets.

I'd rather have 52 small customers hitting different markets than two or three huge customers. The scheduling is a challenge, but if you do it right and put the right people in place, you're going to be able to sustain a steady workflow. We've averaged 45 to 47 hours consistently since 2012.

IMD continually looks to add to its customer base and the markets it serves to be diversified in the areas where the team performs best. This approach helps them maintain consistency as some markets slow, and others rise.

Currently, we have more than 60 customers with a range of work. Of note is newer military work. We became ITAR-certified in 2017. Many of the projects are experimental prototypes that can take two to five years before they go into production. It's a lengthy process, but the end goal is very rewarding because you can get a 5- to 10-year plus contract for production machining work, which is a segment of our diversification that we want to grow in the next couple of years.

Also, three years ago, 90% of our customer base was Wisconsin. Now we are branching out to other states. Work includes mold building as well as sampling and sometimes low-volume production runs. We have a molding department with 55-ton, 110-ton and 250-ton presses. We are not a molder, but it is a value-add service if needed.

Tell me how Innovation Mold has experienced the impact of reshoring?

Hermann: We have had many cases where various customers used offshore tooling primarily because of perceived cost savings. Our entire organization prides itself on designing and manufacturing molds in the U.S. We enjoy working with customers and developing plans to show them that in the long run, quality domestic-built tooling will save money. A quality, high-precision mold will run faster, produce more accurate parts and outlast lesser-quality molds, yielding substantial cost savings.

For example, we have a consumer products customer for the electronics industry that has done all of its tooling offshore for the last 15-20 years. This year, we became the first U.S. manufacturer to build their molds and run their products. They do two launches a year that we want to capture. They reached out to many larger companies but liked our approach, willingness to collaborate, outside-the-box thinking and strategies for improving speed-to-market. For example, instead of building a certain cavitation for a particular mold, we added cavitation. This approach means that we didn't have to build as many tools, so there is less of a window before that product hits the market. We are hopeful about growing this industry segment.

IMD’s company motto is “The best people create the best processes. The best processes create the best technologies. The best technologies create the best products."

Covid-19 put the spotlight on American manufacturing, and not just its value but its resourcefulness. Can you explain it?

Hermann: What is most impressive about all American manufacturing is our ability to redirect resources. You might be a moldmaker today, but tomorrow you're making parts for respirators. You might not be making molds, but you are assembling or cutting paper dies, etc. We have the labor, the facilities and the technology that we can redirect.

Related Content

Taking a Holistic Approach to Training Is Filling a Local Skills Gap

Success coaches through JEVS Human Services’ Tri-State Apprenticeship Program (JTAP) provide guidance and a different way of learning for the whole person for small- to mid-sized manufacturers.

Read MoreMidgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreRead Next

Three Generations of Moldmakers Support Injection Molding and Investment Casting Industries

It’s all about service: a family mold, tool & die shop goes above and beyond for plastic injection and investment cast customers.

Read MoreA Conversation with Big 3 Precision Products Inc.

MMT interviews Big 3 Precision Products Inc., a group that builds injection blow molds, one- and two-step injection stretch blow molds and extrusion blow molds.

Read MoreMichigan Mold Builder Gets Business Savvy and Adds Vibration and Hot Plate Welding Services

Best Tool & Engineering identifies a new niche in vibration and hotplate welding and beefs up its business management skills.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)