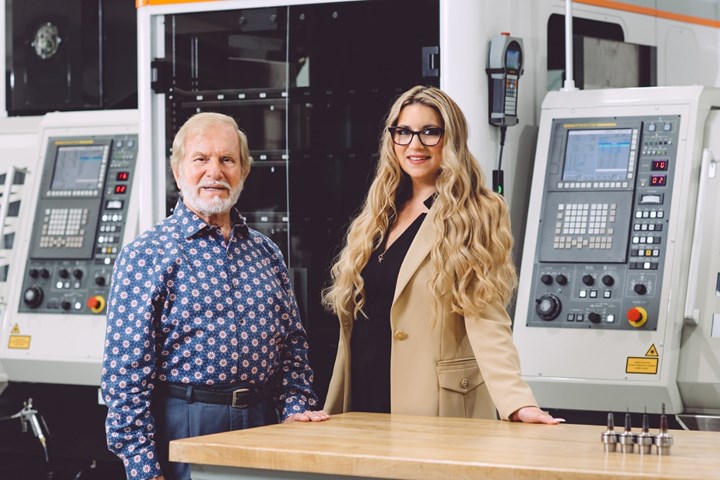

Emilia Loulourgas Giannakopoulos, CEO of American Tool and Mold (ATM) and her father and founder Demetre Loulourgas. Photo Credit, all images: American Tool and Mold (Jeremy Scott)

Who is American Tool and Mold (ATM)?

Emilia Loulourgas Giannakopoulos, CEO, American Tool and Mold (ATM): ATM has been in business in Clearwater, Florida, for more than 45 years. It was founded by Demetre Louourgas, a Greek immigrant who became a proud U.S. citizen in 1981. ATM houses 160 employees (and looking for new talent) in a main 150,000-square-foot manufacturing facility and another 15,000-square-foot hard milling facility on the company’s 10-acre property.

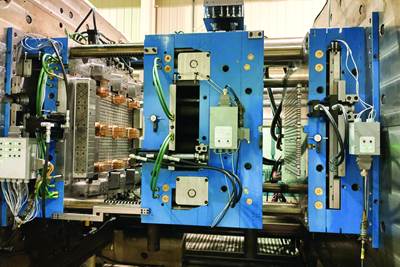

ATM manufactures complex, precision, multi-cavity molds for the plastic injection molding industry for consumer packaging, specialty closures, aerospace and medical industries.

ATM designs and manufactures complex, precision, multi-cavity molds for the plastic injection molding industry. The team provides thin-wall, stack, hot runner, unscrewing and two-shot, high-cavitation molds for consumer packaging, specialty closures and medical industries.

ATM is not only a mold builder; we are also a molder. Over 30 years ago, customers asked us to mold their parts and build the molds. As we took on this work, we learned how to maintain the molds and design the molds to require less maintenance. This includes trying different surface coatings and treatments to extend the life of high-wear mold components. When you can monitor the wear in your facility month after month, you can try different solutions and see which ones work best.

We have 27 modern, high-efficiency molding machines, nine running two-material molds, including 100- to 650-ton KraussMaffei, Husky and Arburg presses. Injection molding presses, a vertical rotary insert molding press and a two-color molding press are available for testing, sampling, conditioning or production.

ATM houses 160 employees (and looking for new talent) in its primary 150,000-square-foot manufacturing facility and another 15,000-square-foot hard milling facility on the company’s 10-acre property.

What is ATM’s mission statement?

Giannakopoulos: ATM exemplifies commitment to the finest in American craftsmanship and dedication to quality. It is a commitment to excellence, precision and perfection in all phases of our business.

We aim to establish and develop long-term customer relationships based on mutual trust and reliance by supplying them with products on time that meet or exceed their expectations. We promote employee training to refine our job skills and improve quality processes and we continuously improve our equipment to meet future customer needs and expectations. Last, we provide a safe and pleasant working environment to promote teamwork and workmanship quality.

What do you view as ATM’s chief competitive advantage?

Giannakopoulos: Experience in two-material molds. We entered this niche many years ago at the request of customers who had problems with other moldmakers trying to build two-material molds. ATM has designed many unique molds with rotating sections for multi-material parts that were well received.

What are some of ATM’s new machine purchases?

Giannakopoulos: ATM invested over $6 million in a high-speed cleanroom for its hard milling facility that offers speeds of up to 40,000 rpm, enabling tighter tolerances with hardened materials such as machining components that are up to 60 HRC. This process eliminates the need for heat treatment after machining, which can cause distortion.

We also have automated multiple EDM machines with more than 460 electrode stations to enable lights-out operation, which has reduced our mold delivery times.

There has been an additional $6 million investment in new equipment this year, including a Toyoda FH 1250 SX horizontal mill with an exceptionally large machining envelope — over 2 feet more Z-axis travel than other machines in its class, — a Proth 4880 wet grinder to increase our plate grindable size from 48 × 60 inches to 48 × 80 inches and a Kitamura 4XV vertical mill with a FANUC controller and 15-inch monitor.

ATM has invested $6 million in new equipment in 2023, including this Toyoda FH 1250 SX horizontal mill with a large machining envelope.

We invested in two Roku HC-658-II vertical graphite milling cells, each with a System 3R WorkPartner 1+ robot with 280 stations to automate our electrode production and maximize our unattended time. In addition, we bought two Mitsubishi MV2400-R wire EDM machines to greatly increase our throughput and capacity and a Hardinge T51 MYT Super Precision lathe that gives us the ability to do a lot of what would traditionally be “grinding work” on a much faster lathe.

Quality assurance is a big deal at ATM. Explain what this means.

Giannakopoulos: Our commitment to excellence is exemplified by our array of prestigious quality certifications. We proudly adhere to ITAR, ensuring the secure handling of sensitive information and materials. ISO 13485 certification underscores our dedication to maintaining rigorous standards in the design and manufacturing of medical devices. AS9100 certification demonstrates our competence in the aerospace industry, emphasizing product safety and reliability.

Our continuous pursuit of operational excellence is evident in our implementation of key performance indicators (KPIs) throughout our systems. These metrics enable us to measure and enhance our performance across various facets of our organization, ensuring we consistently deliver the highest quality products and services to our valued customers.

ATM’s quality department employs years of experience and uses the latest zero-defect methodologies. We combine training, equipment and a systematic approach to ensure that all of our products go out the door right the first time, every time. A seasoned staff from many industries can perform the production part approval process (PPAP), installation, operational and performance qualification (IQ OQ PQ) and first article inspection report (FAIR) standards while working with the customer to develop customized submission protocols.

ATM's two-tiered quality control system involves a machine operator checking all specified dimensions during the process and a lead man rechecking those dimensions after the process.

We use a two-tiered quality control system: First, the machine operator checks all specified dimensions during the process, then the lead man rechecks those dimensions after the process, using state-of-the-art coordinate measuring machines (CMM) and computerized optical equipment. Our gages and measuring instruments are calibrated regularly and certified annually.

We can also perform process capability studies and extended pilot runs during the mold testing/debugging phase. We can supply the customer with full process data with every ATM mold.

What hardware and software does ATM use for inspection?

Giannakopoulos: We use modern equipment for inspection and testing, including three Mitutoyo Crysta Apex C CMMs with scanning and touch probe capabilities. The software is Geopak Mcosmos-2 v4.3 and Cat1000PS.

We also have a Starrett AVR300, an automatic vision metrology system ideal for repetitive measurements and automatic comparison to CAD files. The operator interface is the MetLogix M3 software, which displays a live video image of the part, geometry tools and digital readings. The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch screen monitor. M3 software capabilities include three-axis measurements and 2D geometric constructs.

In the molding lab, we use a CMM Apex vision system with probes and Measurlink software and QVPAK, OGP Smart scope, OGP comparator, Meiji scope and a Mark-10 Force gage.

What is the role of a project manager at ATM?

Giannakopoulos: The ATM project manager is the center of all communications. This person initiates quotes, publishes reports, reviews billing issues, and ensures the accuracy and timeliness of customer commitments.

ATM’s in-house moldmaking expertise and expert molding troubleshooting capabilities improve cycle times and reduce the scrap rate. The team is dedicated to producing quality workmanship, global program management and unique product development techniques.

Provide an example of the most significant change in the business.

Giannakopoulos: It has to be the big increase in our injection molding business. We are seeing companies that no longer want to mold in-house or have had issues with mold maintenance at custom molders, so they want to move their molding business to us.

We will continue to invest in technology. We have a $5 million capital plan for new equipment.

We can often improve the cycle times and reduce the scrap rate. In many cases, some molders do not exercise optimal mold maintenance, such as cooling lines not being cleaned or chillers not working well. Others do not perform cycle optimization in a documented step-by-step process.

We run a 26-machine molding plant and have in-house moldmaking expertise and expert molding troubleshooters, which help us improve cycle times and uptime and reduce scrap rate.

The quality team at ATM has years of experience and uses the latest zero-defect methodologies.

How do you expect your business to evolve in 3-5 years?

Giannakopoulos: We will continue to invest in technology. We have a $5 million capital plan for new equipment. So far this year, we have spent $6 million, and the plan is for multimillion dollar investments in each subsequent year for state-of-the-art moldmaking equipment and new injection molding machines.

Please tell us how you are addressing the skills gap in the industry.

Giannakopoulos: ATM is working with the local high and technical schools by inviting students in to see the high technology the industry uses. We have two 3-year apprenticeship programs — moldmaking and CNC machinist. Six apprentices split their time between school and work in the shop.

We work with Pinellas Technical College (PTC). Three ATM employees teach at PTC at night. We also have a Manufacturing Day at ATM every year. The curriculum is from the National Institute of Metalworking Skills (NIMS), with 11 certificates for apprenticeship completion.

ATM promotes employee training to refine job skills and improve quality processes and provides a safe and pleasant working environment to promote teamwork and workmanship quality.

Describe the most interesting/notable mold project your company was awarded.

Giannakopoulos: ATM received an order for two high-cavitation multi-material molds for a COVID-related medical component. Using our new automated EDM lines, we delivered molds in fewer than 15 weeks and qualified at the customer’s plant within 5 days. The customer wanted to be running production 20 weeks after giving us the order for the molds. We were able to exceed his expectations with a new part.

The key to beating the schedule was a kick-off meeting where each group was aware of their part and the schedule they had to meet or beat. In this team approach, each group knows what to do to meet the customer’s expectations and not disappoint the rest of the team. Progress is monitored and shared weekly. When the job is completed ahead of schedule, this is communicated to all team members and celebrated.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreICYMI: MMT Chats: True Leadership Leads to Mentoring, Part 1

This trio from TK Mold and Engineering in Romeo, Michigan, joins me to discuss the role of leadership and culture in mentorship. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MoreHigh-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)