WEBINAR: The Key to Digital Tooling Is Ceramic Fiber Reinforcement

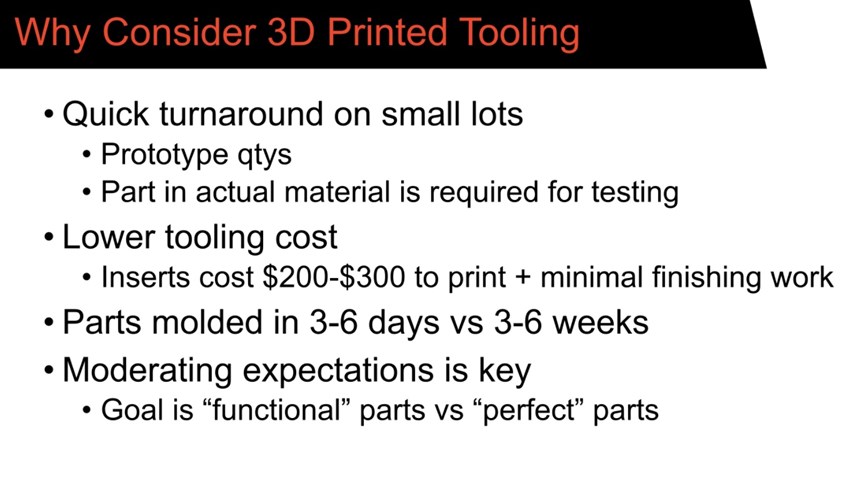

If you do low-volume prototyping then this ceramic fiber-reinforced 3D-printed tooling option could be worth a look ... or listen. Check out this free webinar that presents best-use applications, part and mold design considerations and key lessons learned.

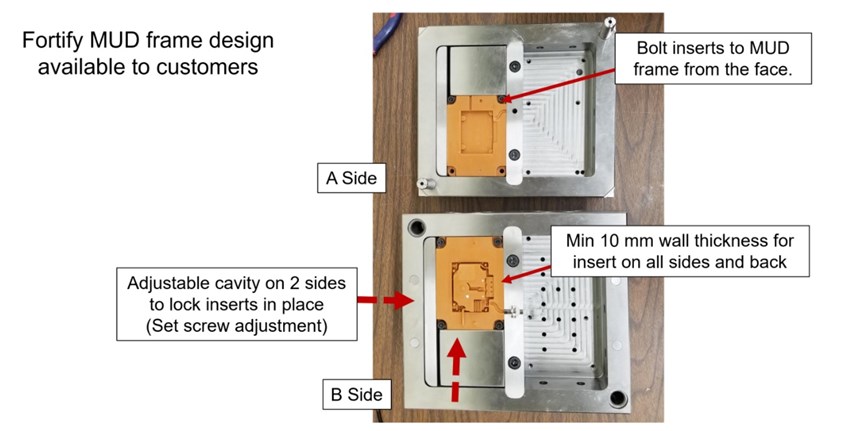

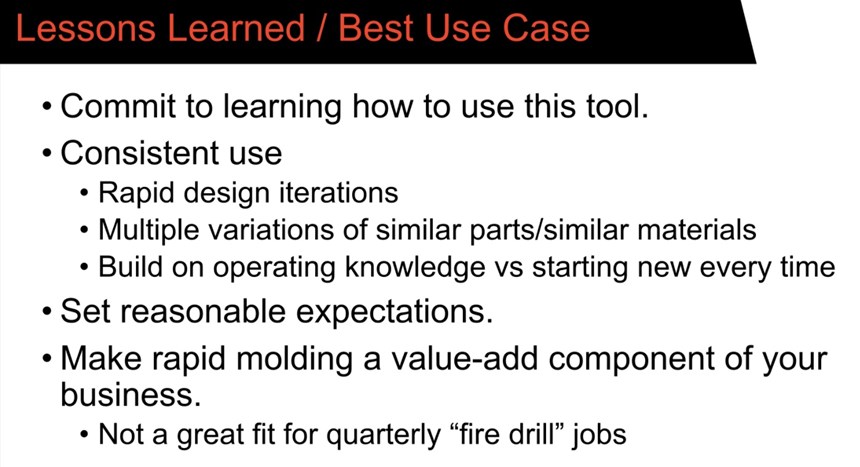

Solving specific problems and sharing best practices is the way Fortify is educating mold manufacturers and molders about its ceramic fiber-reinforced 3D-printed cavity and core sets for low-volume prototyping.

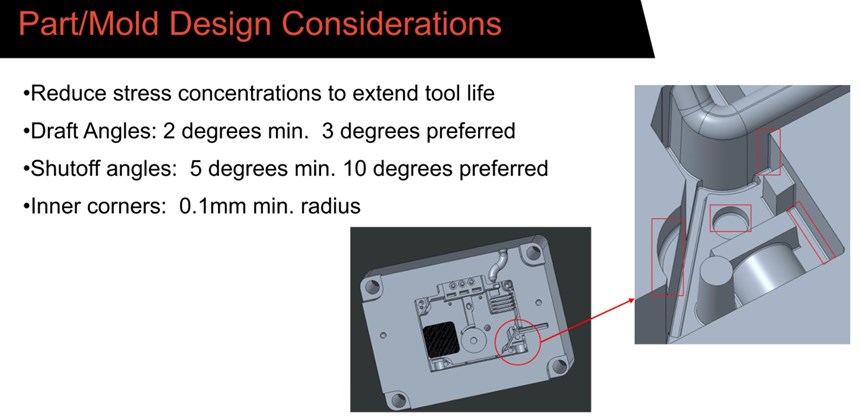

Ben Arnold of Fortify and John Eastham of Ideal Systems team up for a free webinar that presents a little history of Fortify’s technology platform (digital composite manufacturing), details on the beta machine set to hit the market in early June 2020, the importance of ceramic fiber reinforcement, material properties and tolerances, part selection, design guidelines, ejection, ramp up and operation, cooling and cycle time, and best practices for using reinforced 3D printed tools.

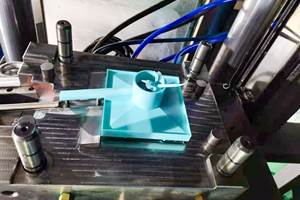

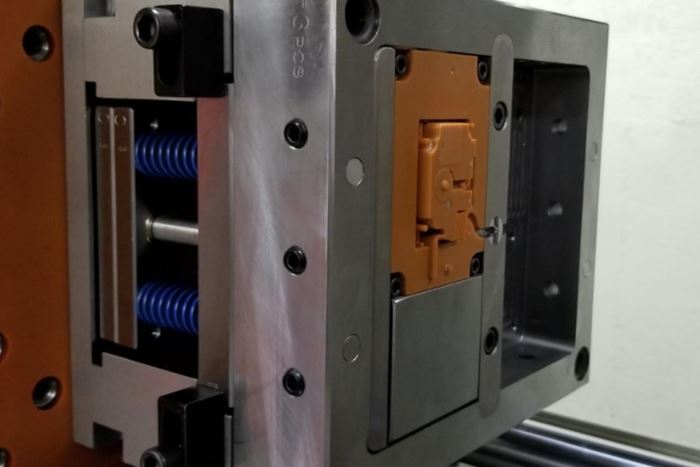

reinforced 3d-printed tooling

A 30-minute Q&A session includes answers to questions like the following, and many more:

- Are part properties different when molded in a 3DP tool?

- Can you use conformal cooling channels with these tools

- How long does it take to have a tool ready for molding?

- How much prep work is needed?

- Can we make tools with side action? Hand loads?

- Can you explain the 3d printing process steps?

- Can these tools be autocycled or do they always need an operator running the machine?

- Will you take my CAD file and print inserts for me?

- How much post-processing is required?

If you are interested in hearing the answers, click here to register and get access to this free 50-minute webinar.

Related Content

From Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreEvaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)