Milling, Wire and Sinker EDM Equipment Optimizes Production

MC Machinery features several of the company’s innovative milling, wire and sinker EDM equipment.

MC Machinery features several of the company’s innovative milling, wire and sinker EDM equipment.

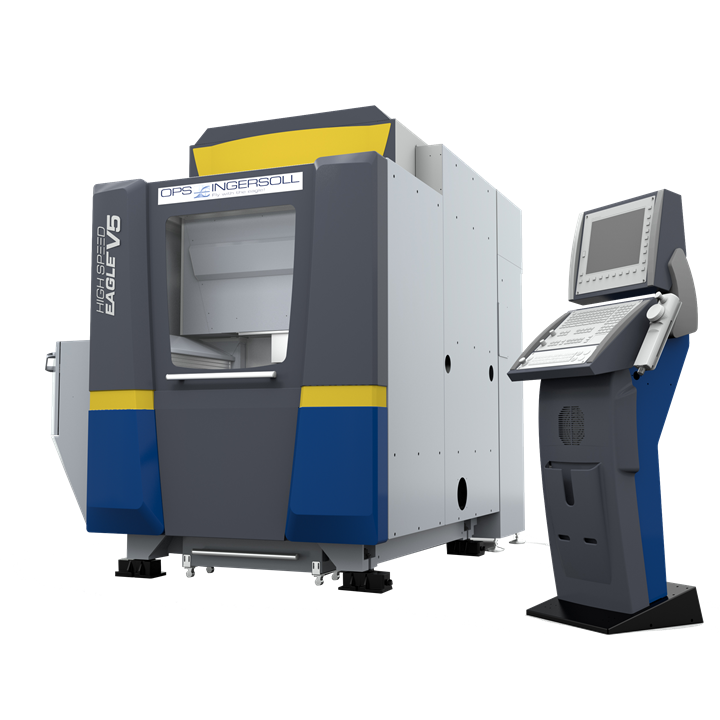

Capable of simultaneous five-axis machining, the OPS Ingersoll Eagle V5 five-axis milling machine is built for rigidity and fine precision. The machine is built with a 42,000 rpm, integrated spindle, a heavy-duty, roller-type linear glass scales in both the X and Y-axis. It also comes standard with a Heidenhain iTNC-530 control unit mounted on a moveable pedestal for convenient positioning.

Built for general-purpose or intricate milling work, the DV800 CNC milling machine includes a 15,000 rpm direct drive, Big Plus spindle. The machine includes the Mitsubishi M80A Series control with a 15-inch touchscreen with cell phone-like functionality and 135,000 block per minute calculation speed.

The EA12S Advance Sinker EDM features an advanced Mitsubishi control, the M700 with a 15-inch touchscreen. The machine’s unique FP89S energy-saving power supply reduces electrical consumption 20% more than the previous FP generation. GF2 adaptive control reduces electrode wear as much as 80%, while the new SS Jump 5 optimizes acceleration to stabilize high-sped, no-flush burning.

Ideal for small-part manufacturing, the MV1200-S Advance M800 wire EDM sinker system includes powerful standard features like auto-threading, internal machine communication and power supply control technology. Another step in Mitsubishi EDM’s continued focus on improvement, the machine includes the revolutionary M800 series control with a 19-inch cell phone-like touchscreen control with common shape macros that can reduce programming by as much as 88%.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)