Gas-Heated Furnace Optimizes Mold Preheating

Grieve’s furnace heats up to 2000°F(~1093.3°C) and 7-inch-thick floor and wall installation enable consistent heating.

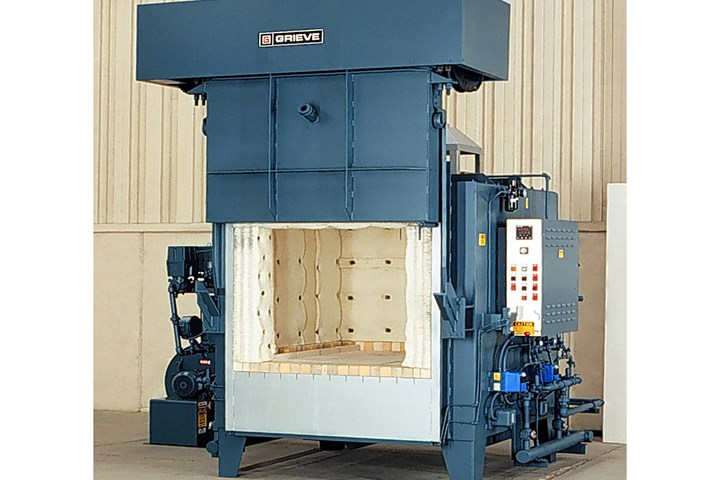

Photo Credit: Grieve Corporation

Grieve Corp. introduces No. 862, a gas-heated 2000°F(~1093.3°C) furnace currently used for preheating molds. The furnace has 750,000 British Thermal Units per hour (BTUh) installed in four modulating natural gas burners with a floor-mounted combustion air blower. Workspace dimensions are 36 inches wide x 48 inches deep x 36 inches high.

The unit retains 7-inch-thick insulated walls, comprising 5 inches of 2300°F ceramic fiber and 2 inches of block insulation. The 7-inch-floor insulation contains 4 ½ inches of 2300°F firebrick and 2-½ inches of block insulation.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door. All safety equipment required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-heated furnaces is also included.

Related Content

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

-

How to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

_300x250 3.png;maxWidth=300;quality=90)