Advanced CNC Programming Interface Streamlines Tool Management

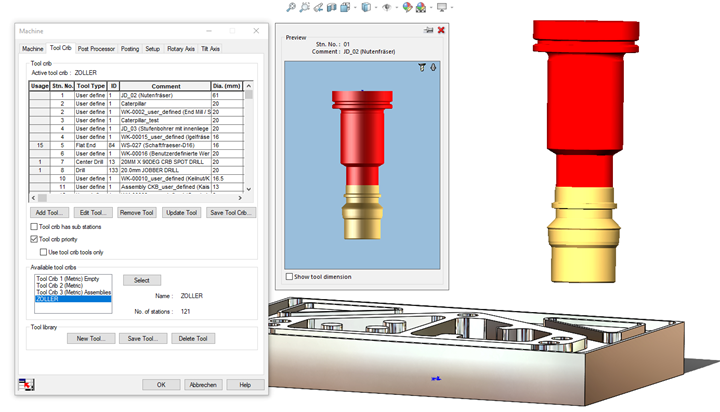

HCL announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software to decrease manual entry of tool data and eliminate the need for multiple databases.

Photo Credit: HCL Technologies

HCL Technologies (HCL), a global technology company, announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software. The Zoller Interface is said to supply customers with advanced tool database management options, an overview of available tools and eliminate the need to maintain multiple tool databases.

With the Zoller Interface in CAMWorks, tool data is standardized and the exchange of data between the two software systems is automated. Customers only need to enter the information for their cutting tools in once into the central Zoller tool database, HCL says, and the tools are imported automatically into CAMWorks. All of the tool parameters are captured, including contour line for holder and cutter, specific tool type and technology data, such as feeds and speeds. The interface also enables users to define tools in the Zoller TMS Tool Management Solutions software with the same tool types and parameters that are being used in CAMWorks.

Once a part model is programmed, the Zoller Interface generates a setup sheet that includes a list of tools used for the part. The setup sheet assists with tools assembly, measurement and sending measured values to the machine for cutting the parts. According to HCL, the interface decreases manual entry of tool data and streamlines tool management.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.