StackTeck's 2019 Initiatives

StackTeck Systems announces the company’s first moldmaking plant outside of North America.

The moldmaking facility in South Korea began as a subsidiary with a focus on building molds for PET preforms, medical and packaging applications. This facility will now be called StackTeck Asia.

StackTeck Systems will serve its existing customer base with additional service support available from StackTeck Asia. John Yu, senior board director for StackTeck, says that the range of products and abilities of StackTeck Asia are especially suited to support the company’s business in the region. For customer service outside of North America and Asia, the company has service providers in Australia, Italy and Latin America so that technical support and mold modifications can be provided in each continent.

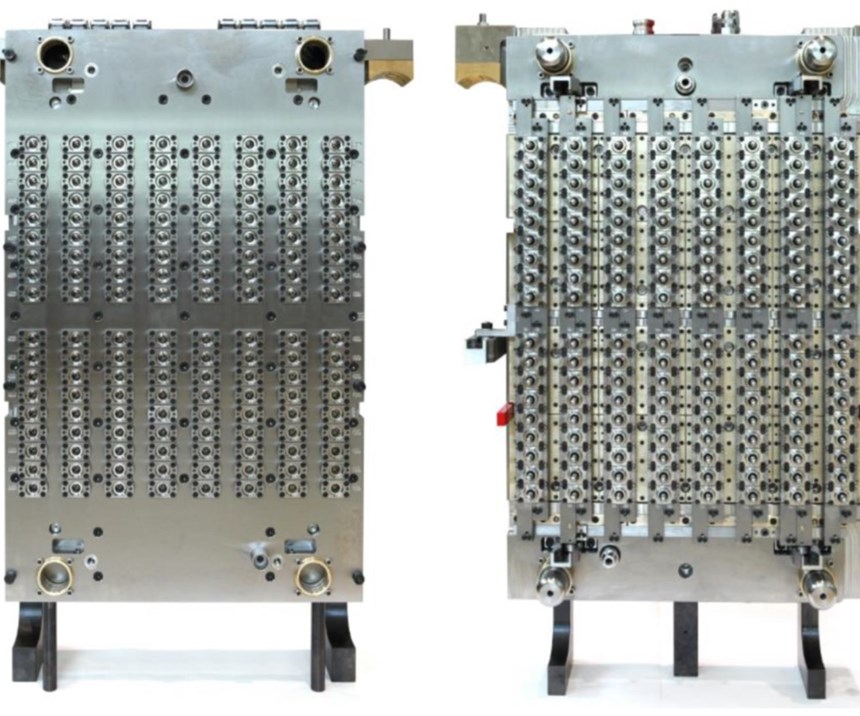

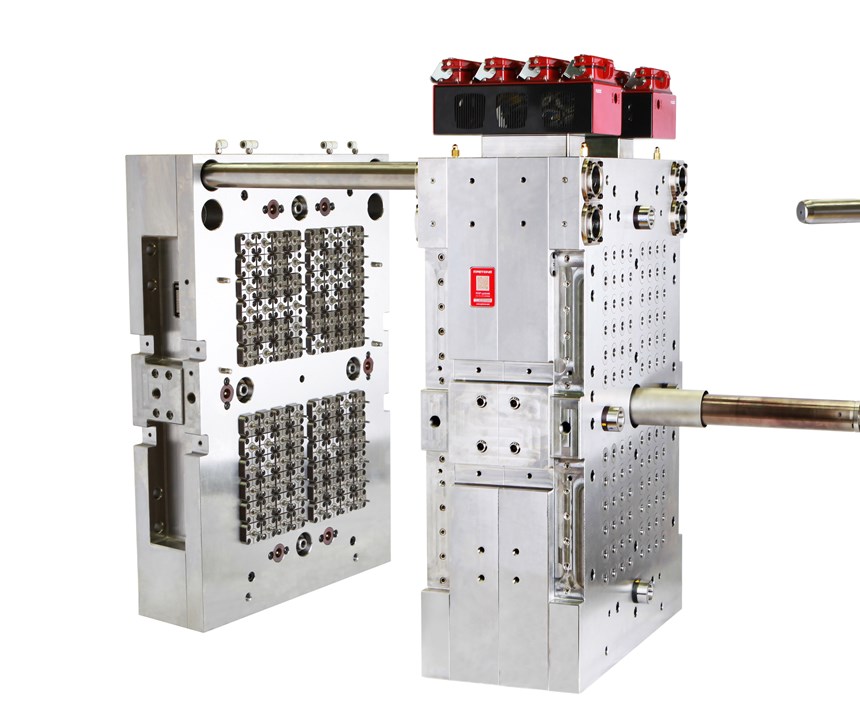

For PET preform molds, Rick Unterlander is taking on the role as General Manager focused on PET preform projects in the Americas, and will act as liaison to StackTeck Asia, working with machine suppliers. Over 100 PET preform molds have been built to date, including a number of high-cavitation molds running in Japan. In addition, prototyping services, automation and advanced post mold cooling systems are available. These PET preform molds are offered with hot runner technology using an advanced design that is said to enable reduced pressure drop, improved balance and lower AA levels than conventional designs. Custom designed molds are available to suit existing machine/automation configuration.

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.