Focus on Performance: GF AgieCharmilles hosts Technology Days 2011

With a focus on improved performance and new applications, GF AgieCharmilles Technology Days 2011 offered educational seminars and machine demonstrations to an estimated 170+ customers, technology partners, and industry press.

The two-day event was held June 29-30 at the company’s North American headquarters in Lincolnshire, Illinois.

The program included seventeen educational seminars on topics in AgieCharmilles’ areas of focus, including milling, EDM and laser technology. Each seminar was offered on both days of the event, but the schedule was varied to provide attendees the best chance of covering several topics. Presenters included representatives from partner companies (such as EOS, Frasia, Mastercam, Open Mind, and OptiSolutions) as well as by GF AgieCharmilles product specialists.

Seminar Highlights

Mathieu Tapp, CEO of cutting tool supplier Frasia USA, discussed Cutting Tool Coatings and Edge Preparation. Today’s multi-layer tool coatings are complex, he said, and can go a long way toward reducing adhesion and protecting against abrasive wear on cutting tools. A key factor to remember is that coatings are application-dependent; there is no single “best” coating. Frasia develops its own specialty coating technologies, but will sometimes use another supplier’s coating if they believe it best suits a customer’s specific application. “Make sure your tool supplier understands your needs, and that they consider every technology available,” Tapp advised attendees.

AgieCharmilles Product Manager Eric Ostini discussed the company’s IQ Technology in his seminar, Reducing Electrode Cost – Saving Plastic in Moldmaking. For certain specialized applications (such as those that utilize undersized electrodes or electrodes with complex shapes), applying IQ Technology can significantly reduce total cost – due not to a shorter cut time, but to reduced wear, fewer setups and other factors.

Toolholding is an often-overlooked factor in efficient operation, said Bill Obras of Rego-Fix Tool Corp. in his seminar on Toolholder Selection for High-Speed Milling. “You can have a great new machine, and you can use the coolest new tools, but remember that the toolholder is the critical link,” he told attendees. He provided hands-on models of a variety of high-performance toolholders, and noted the benefits and drawbacks of each.

Machine Demos Draw Interest

With sixteen operating machines on display, Technology Days attendees had plenty of opportunity to learn about AgieCharmilles’ latest offerings. Drawing particular attention was the HSM 400U LP, which provides 5-axis simultaneous high-speed machining with a high level of precision on all five axes. The HSM 400U LP uses a linear direct drive motor, which eliminates backlash and promises exceptional speed. According to the company, The HSM 400U LP’s optional pallet changer with 20/48 pallets supports 24/7 unattended machining.

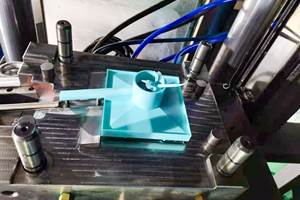

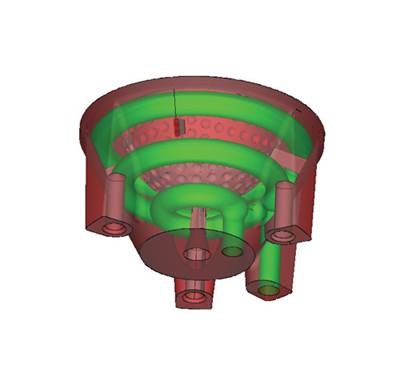

Another popular machine demonstration was the EOSINT M280 (from EOS GmbH). This laser sintering system uses additive layer manufacturing to produce tooling inserts, prototype parts, and end products with features (such as curved cooling channels in specialty molds) that are not achievable with other processes.

AgieCharmilles Applications Engineer Tony Zwiener told MMT that the company hosts events like this at least once a year, alternating among its four U.S. locations to make it easy for customers to participate. “This year we’ve had a great turnout – even more than expected,” he said. “We thought customers would be coming by just to say hello and pick up some new information; but there’s also been a lot of purchasing interest too. I expect we’ll be selling a few new machines after the event.”

GF AgieCharmilles supplies machines, automation solutions and services to the tool and moldmaking industry as well as to manufacturers of precision parts and components. The company is part of Swiss-owned Georg Fischer Group, with more than 2500 employees and 50 locations around the world.

Machines on display at Technology Days 2011:

- CUT 30P Wire EDM

- CUT 300 Wire EDM

- Cut 1000 Oil Tech

- CUT 2000 AWC Wire EDM

- Drill 20 High-Speed Hole Drilling EDM

- EOSINT M 280

- Focus 3

- FO 550 SP Diesinking EDM

- FO 350 MS Diesinking EDM

- FORM 20

- FORM 400 Diesinking EDM

- FW 2U

- Hexagon CMM

- HSM 500 High-Speed Machining Center

- HSM 400 U LP 5-Axis High-Speed Machining Center

- Laser 1000 5Ax Laser Ablation Center

Related Content

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreTechnology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreAdvancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

Read MoreRead Next

Seamless Process Creates the Impossible Cooling Channel

A multiple-machine moldmaking process—combining DMLS, high-speed five-axis machining and EDM— produces conformal-cooled molds in a seamless automatic process.

Read MoreSeamless Process Creates the Impossible Cooling Channel

A multiple-machine moldmaking process—combining DMLS, high-speed five-axis machining and EDM— produces conformal-cooled molds in a seamless automatic process.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)