Taking Advantage of Carbide Material for Your Mold Designs

The development of an end mill that can cut 3D features into a carbide material demonstrates how mold manufacturers can reap the benefits of carbide material for their mold designs without a time or cost penalty.

For quite some time, carbide has been the material of choice for most cutting tools—such as drills, end mills and indexable inserts. As a material, its hardness, durability and sharp cutting edge support have enabled cutting tool manufacturers to provide users with the ability to mill hardened steels—with the addition of advanced coatings—that were once thought impossible on a daily basis. This is hard milling as we know it today.

Recently, for many of the same reasons, mold manufacturers have wondered how carbide material might offer them the same hardness and durability for their molds. After all, it will support small features and details, provide a great surface finish and offer great durability—enabling it to sustain many shots over a longer life cycle, which helps bring down costs.

However, just as the cutting tool manufacturer has to grind the tool’s shape or form, the moldmaker is forced to do the same or use EDM. Both of these processes are very capable, but can limit the feature size or detail to be formed in the case of grinding—or in both cases take considerable time and cost.

The ideal solution is direct milling—straight from the CAM program—just as for hardened steels. However, the question is “How can carbide be milled reliably and economically?”

Analyzing Carbide

The answer to this question came into focus in early 2011 as increasing requests for a solution became apparent. What was needed was a strategy to combine advanced micro end mills with advanced coatings and then develop a manufacturing process, along with application data for the user.

Testing1 proved that diamond coating offered the right balance of durability and cost when compared to cBn or PCD technology. Also a diamond-coated carbide end mill has a much higher degree of anisotropy, so it can better withstand vibration and chatter.

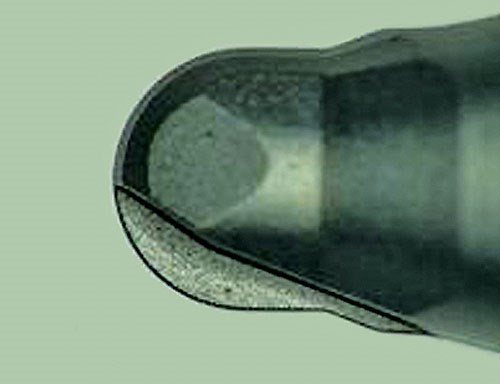

Using a hot filament chemical vapor deposition (CVD) technique gives a more homogenous and consistent coating, particularly on complex shapes such as the geometry of a ball end mill. The coating also had to attain a hardness to combat the hardness of the cemented carbide workpiece, and ideally be close to the same hardness of a single-crystal diamond—about 9,000HV.

Another key point was to obtain the near total adhesion to the end mill’s surface to prevent peeling. This was achieved through a precise process that controls the interface of the two materials at point of contact.

Finally, due to finished part tolerance demands as well as to ensure repeatable cutting tool performance, a consistent thickness of coating is required to fully maintain optimum cutting edges.

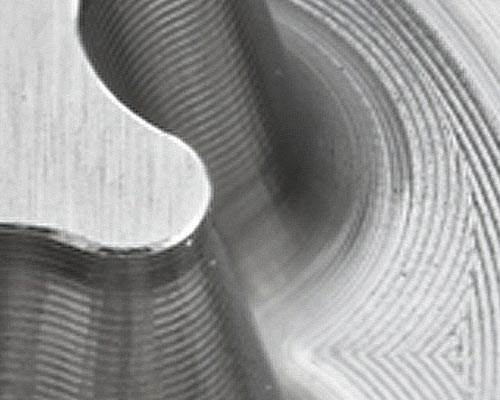

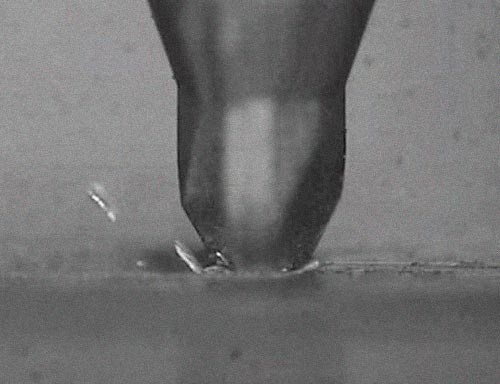

This point is one of the main advances because testing showed that the right combination of geometry design and coating properties enables the end mill to physically cut the carbide into small chips, making a clean and burr-free surface on the workpiece.

During the test phase, all the most common coolants were evaluated and while all performed well, the final recommendation was air blow because it is both ecologically more suitable and the chips do not form into a paste as is sometimes seen with oil mist.

The result is an end mill with the capability to reliably and consistently “cut” 3D shapes and features into cemented carbide.

Test Cut

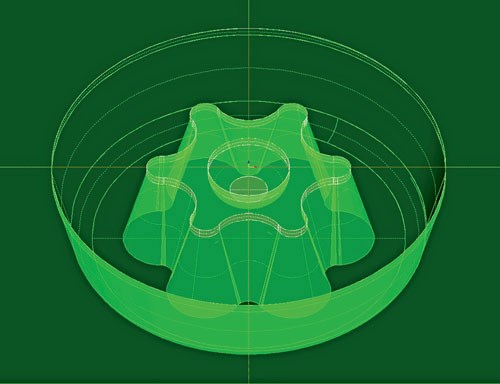

As an example, a 9-mm diameter aperture with a 3D hexalobular center feature was designed and used to test a 1.00-mm diameter ball end mill, featuring the diamond coating and geometries outlined in this article.

The workpiece chosen was VF-20 cemented carbide rated to 92.5Hra hardness with a grain size of 0.5microns in a 13-percent cobalt. The material TRS is stated at 4,500-5,000Mpa.

Using a high precision, shrinkfit toolholder on a CNC machine, parameters were set to 30,000rpm, 300mm/min feed with an Ap 0.05mm and Ae 0.30mm (roughing) and Ae 0.005mm (finishing). A helical approach was chosen to ensure even load on the tool as the force required to cut cemented carbide is around three times greater than for a hardened tool steel. As noted previously, air blow was chosen for the coolant.

The cycle time using a conventional EDM method was calculated at about 3 to 4 hours with the associated costs of preparing electrode material. The total cycle time using a direct milling method was 39 minutes using a single tool.

A total of 91.7mm³ of material was removed at a material removal rate (MRR) of 2.35mm³/min.

At a recent international exhibition, this case study was repeated daily and after each cycle the 1.00-mm diameter ball end mill was measured for degradation and tip wear. The results showed less than 1.8microns of tool wear. The objective was to produce a clean, burr- and pit-free part that could be reliably recreated each time while maintaining the required tolerance to the original program.

Summary

The development of an end mill that can cut 3D features into a carbide material is a key to unlocking the original question regarding how mold manufacturers can take advantage of carbide material for their mold designs with all its benefits, but not incur a time or cost penalty creating the detailed features that would justify carbide’s selection in the first place.

References

1 Testing was conducted by Hide Watanabe PhD at Union Tool’s Nagaoka, Japan, Technical Center, which formed the basis of a patent for the diamond coating that was subsequently selected for this product.

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreMMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan. This episode is brought to you by ISCAR.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

Afraid of Pushing Your Cutting Tools?

How advanced software and cutting tool technologies take the fear out of pushing your tools.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

_300x250 4.png;maxWidth=300;quality=90)