Strategies for Evaluating, Maintaining Equipment

This year's Leadtime Leader award winner doesn't settle for just any test cut to evaluate a machine's capabilities. Once it does make a purchase, the shop's approach to ensuring those capabilities don't deteriorate is anything but cavalier.

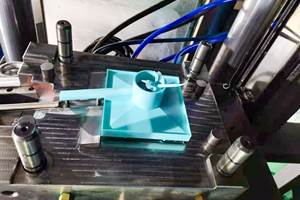

The "angry monkey." (All images courtesy of Creative Technology Corp.)

Cavalier Tool & Manufacturing, this year's Leadtime Leader award winner, doesn't put much stock in many of the tests suppliers conduct to demonstrate the capabilities of their machining centers. "Nobody cuts stuff like that," says company president Brian Bendig about many common tests, which he describes as "overly complex" and "generally unrealistic."

How, then, does the shop verify whether a milling machine will perform as advertised? It insists on using a test of its own choosing. All machines, regardless of size or configuration, are tasked with cutting the part shown above, which was originally designed by one of the company’s regular technology suppliers. Measuring about 5 inches square and referred to by staffers as “the angry monkey,” this test piece ensures that any potentially major purchase is evaluated according to Cavalier's own standards rather than what a supplier might wish to emphasize.

Peaks, curves, concave and convex surfaces—the geometry is representative of the type of work a machine will see day-in and day-out on the shop floor at Cavalier. Likewise with the acceleration/deceleration settings, feeds, speeds and other parameters employed to cut that geometry. In addition to providing a realistic representation of actual machining conditions, using the same test repeatedly ensures that the only variable is the machine itself. "Some builders will say this isn't fair, that a 1-m machine is different than a 2-m machine, and I agree with them," Bendig says. "But the idea here is that the results are in the workpiece. Do the test on two different machines of the same size, and it'll be consistent."

Cavalier Tool & Manufacturing sets itself apart through technology like this Makino MCC 2013 VG HMC. Six axes of motion and FCS fixturing streamline setups and reduce labor costs, Bendig reports. All machines in the shop undergo preventive maintenance according to a strict schedule.

Although it doesn't usually keep machines for long, the shop also has a system in place for ensuring any new purchase will perform the test just as well as the day it was installed for years to come. Cavalier divides maintenance into two types of service: major and minor. Minor maintenance involves checking fans, oil filters and other such components. Major maintenance is far more involved and might take multiple days to perform properly. This involves laser-leveling the machine, checking for backlash, checking the bearings and other internal components. Each and every machine in the shop undergoes both types of service at least once a year according to a strict schedule.

Selecting just the right technology and ensuring its capabilities don't deteriorate is particularly critical for Cavalier. Every mold shop relies on technology, but Bendig makes a point to cut no corners when it comes to differentiating the operation. "The last thing I ask about when buying a machine is price," he says. “Some people might say they can’t afford it,” he adds about technology that can help build a better mold, “but we say we can’t afford not to have it.”

In fact, Bendig says the latest technology is worth jetting around the world to find, and many of the machines on the floor are a result of doing just that. To learn more, read this June-issue feature article on all the factors that earned Cavalier Tool & Manufacturing the 2015 Leadtime Leader award.

Related Content

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreUsing CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

Read More3D Scanning Quickly Solves Tool Repair Problems

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More.png;maxWidth=970;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)