Quickly Getting to the Root of the Problem

Diagnostic device helps molders simply check hot runner cables to ensure connectivity.

How much time do your maintenance personnel spend tracing wiring issues or identifying faulty heaters and thermocouples? Are they frustrated with old-school methods and the time it takes to identify the problem? How many hours do they waste checking a mold for issues only to find that a faulty cable is to blame?

Clack Corp.’s Rogers, Arizona, injection molding facility encountered this issue many times and found a solution in the CableXChecker cable testing system, distributed by Milacron’s DME Co. brand.

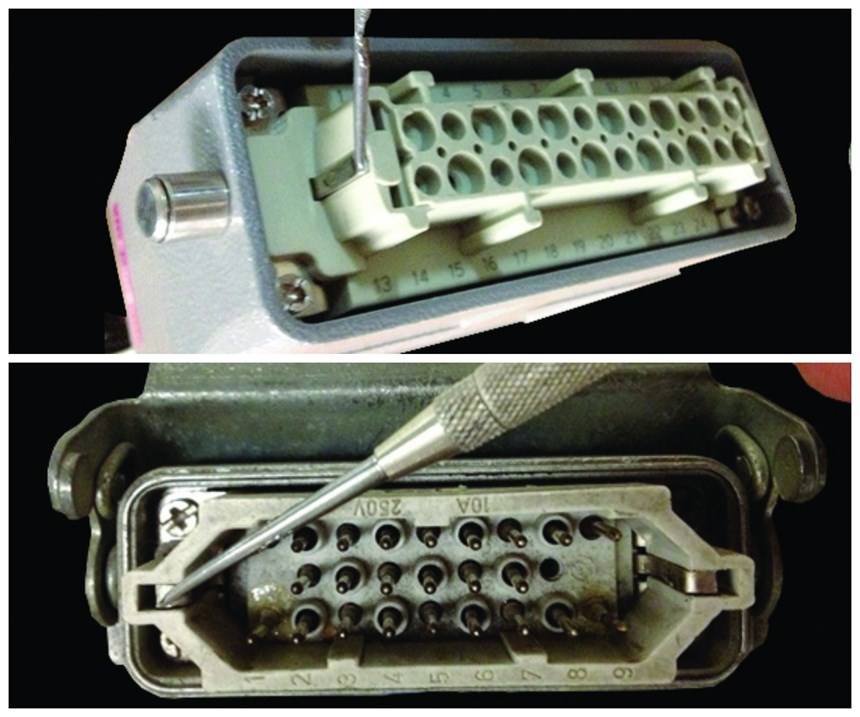

“Before, the best way to test a cable (either thermocouple or power) was to hold the cable between your legs and touch a multimeter to each contact point/pin,” says Michael McCutcheon, product manager for DME Industrial Supplies. “This required 576 point-to-point contacts to diagnose a 24-pin cable. Then, once the cable was repaired, this process had to be repeated to confirm the repair was completed correctly.”

The CableXChecker, manufactured for DME by Fast Heat Inc., enables maintenance personnel to cycle through a 24-pin cable in less than one minute, he says. “This will allow them to quickly rule out cable issues by confirming positive connection between the controller and mold on all zones quickly and safely.”

Gary Ash, Clack’s maintenance supervisor, confirms that the device speeds the diagnostic process. “In the real world, a mold setup person sets the mold, plugs in the hot runner and turns it on. Then, when a zone is not heating, what is the first thing you do? Where do you start? Do you start checking at the mold for shorted or open heaters, the cable, or the controller?”

With the CableXChecker, he simply plugs it in and turns the selector switch from zone to zone, and it tests the continuity of the entire cable. It can also identify shorted cables. “I can check thermocouple cables and power cables in just a minute or two, and I can eliminate or prove cable or plug failure in a couple of minutes instead of the 30 to 45 minutes it takes to get out a meter, jumper cables and alligator clips, and painfully check, pin for pin, each end of the plug,” he says. “Six times out of 10, the failure may not present itself until the cable is jiggled or moved.”

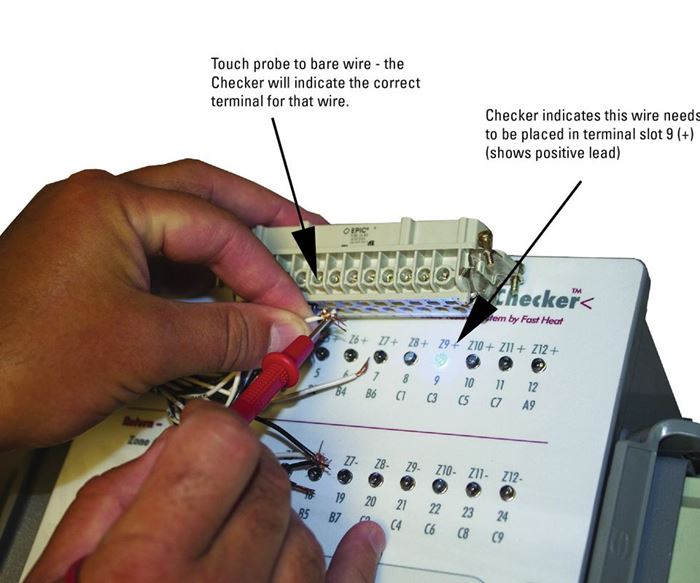

According to McCutcheon, the device was developed to help molders simply and quickly ensure connectivity in all zones and identify pushed-in pins, damaged pin crimps and unseated sockets. “This is done by using the same connectors your controller and mold use,” he says.

He says the device greatly reduces the possibility of human error, because it so simple to operate. The technician connects cables, one at a time, to each side of the CableXChecker, then he turns the dial through each zone, as corresponding lights confirm each circuit. If at any point an LED fails to light up, a short has occurred in that zone. If multiple LEDs illuminate, a short between those wires/zones has occurred. If an LED for a different zone lights up, the cable was wired incorrectly.

Easing the Process of Elimination

McCutchen says the tool ideally should be used to check cables before they are installed on the mold in order to prevent production downtime.

“The CableXChecker provides one step to quickly test the cables, then you can move onto the mold. It also allows you to test and verify your cables before setting up the process,” Ash confirms. “Or, if you suspect a bad cable and you go to get a spare, you can check the spare before you put it on. If we had a problem with a zone prior to having the CableXChecker, we had to get another cable and try it first without knowing if that cable was good.”

At the end of the day, Ash says use of the device cuts downtime dramatically “by the simple fact that it relieves one of the steps of the elimination process.” He also confirms that the device is simple to use, which means any one of the mechanics in his shop can use it effectively. “I no longer need the most skilled electrician in the shop checking cables,” he says.

Related Content

Portable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreMost-Viewed Content of 2022

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

Read MoreHow to Maintain Heaters, Thermocouples, Valve Gates and Controls

An examination of real-world problems and solutions involving hot runner system maintenance.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreRead Next

For Better Mold Venting, Start with the Metal

Selecting the right material for specific mold components can help prevent a number of costly issues.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)