K’NEX/Rodon Team Makes Strong Case for U.S. Manufacturing

Rodon takes a solid relationship with toy giant K’NEX and applies its business model to other manufacturers—taking domestic manufacturing to the next level.

The Rodon Group (Hatfield, PA)—a mold manufacturer/molder serving a diverse number of industries like consumer products, medical, construction, pharmaceutical and toys—also is the manufacturer of more than 30 billion parts for the K’NEX building toy system (and is a subsidiary of K’NEX Brands, L.P.). Since its inception, The Rodon Group has attributed its success to a niche of close-tolerance, high-volume parts; and consequently seeking out work from other OEMs that fit into this “model” that Rodon has built with K’NEX.

Building a Business Model

According to Lowell Allen, Rodon’s Senior VP of Manufacturing, Rodon’s beginnings were in the 1940s as ELGO Rubber. The owner of the company, Irv Glickman, realized making rubber was a laborious process so Glickman switched its specialty to thermoplastics as working with this material started gaining popularity in the U.S. In 1956, ELGO purchased a building in Southampton, PA and The Rodon Group was born with four injection molding machines. “Since then, Rodon has grown, to 106 molding machines with servo robots on more than a third of them,” Allen says.

In 1991, the idea for K’NEX came about when Irv’s son Joel had designed and built some toy parts. “Fortunately for Joel he had a nice injection molding company at his disposal,” Allen notes. “K’NEX has grown into a dynamic toy company— and the only toy company making toys on a mass scale in America. Rodon does all of the mold and part design in-house and runs the parts for them. They are a sister company. We are a custom molder/moldmaker first, but this is a perfect fit for us. High-volume, close-tolerance parts is our forte; and the K’NEX work was a nice addition to our standard business. We want to have as wide a base as we can to diversify and not have all of our eggs in one basket. We make over a billion parts a year for K’NEX and just as much for our other customers combined.”

The Rodon Group’s successful relationship with sister company K’NEX has allowed the company to apply the same principles of high-volume, close-tolerance, custom-molded parts coupled with long-term relationships and mutual trust—to all of its customer relationships. Allen notes Rodon is fortunate that K’NEX is only a mile down the road. “We work closely with their product design and development people in face-to-face meetings, via email, CAD and 3-D printer support,” he comments. “Although they are a sister company and a very good customer, we treat them as we do all of our customers. We do know the players better because we deal with them on a repeat basis, but since all of our customers fit our business model, it is just a different flow chart for K’NEX versus our other customers. The information required is the same; the process is the same—from designing and building to running the parts. We are very proud of the fact that everything is standardized and automated, and we pretty much exercise this successful model across the board.”

The process begins when K’NEX gives Rodon the part design. Rodon quotes it and begins the design and build process, tool cavitation based on annual usage, then samples the part via a prototype cavity to prove out fit and function. VP of Tooling and Design Chuck Rodgers notes that although Rodon has the latest in CAD/CAM software from Mastercam to aid in mold design, it’s the interaction between Rodon and its customers that makes great parts. “When our customers approach us with a part design, we go back and forth to simplify or alter the part and make it more moldable, or reduce the cost of the part by making some changes to the tool and that aids in the speed in which the tool is manufactured,” Rodgers elaborates. “This dialogue is a give and take in an effort to mold in the most efficient way possible while sustaining a long-term relationship with them. This is an ongoing process which occurs with K’NEX and every other customer. It is standard procedure with every job we do.”

Stable of Suppliers

In addition to solid relationships with its customers, Rodon has also forged similar relationships with its suppliers. The company has seen advances in 3-D printers and software in regards to speed and accuracy. According to VP of Sales and Marketing Kevin McGrath, since the company has been around for more than 50 years, Rodon has familiarized itself with many major suppliers “We deal with all of the major players with regards to high-volume resin, tool steel, mold bases and equipment,” McGrath points out. “We are constantly researching what is new by attending and exhibiting at trade shows as well as reading trade magazines. When we find a supplier, we look to stick with them, and we generally form a friendly partnership.. That way, when times get tough it is nice to know there is someone to depend on.

“Conversely, our suppliers know that they are dealing with a high-volume house that isn’t going to jump around and go to someone else to save a few cents a pound on material or a few bucks for a mold base,” McGrath continues. “We are loyal; therefore so is our supplier base. We maintain a good stable of high-quality suppliers for all of our products. New things come along all of the time, which they share with us, such as new grades of products and raw materials.” McGrath adds that these advances result in the company’s increased speed, accuracy and closer tolerances—thereby reducing time-to-market.”

Equipped for Efficiency

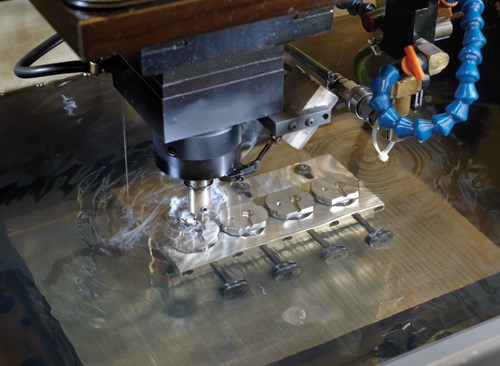

The mantra throughout Rodon’s building is efficiency. “We are constantly asking ourselves how we can become more efficient and more automated,” Allen states. “We use technology as our tool to battle offshore competition. We recently replaced two machining centers and one piece of CNC/EDM equipment in our toolroom; and are currently looking at a high-speed hard milling machine. Again, all of this reduces time-to-market. If you reduce time in the toolroom and reduce your costs, these savings can be passed along to the customer. Staying on top of rapidly changing technology is the key to staying up-to-speed and maintaining a competitive edge.”

As for training and workforce development, Rodgers acknowledges the company faces some challenges. With fewer people entering the moldmaking field, Rodon has actually started to actively seek out apprentices. “We have hired several from local applicants who are mechanically inclined, as well as through personal references and tech schools,” he states. “We have developed a four-year, internal apprenticeship program. It’s been difficult but there doesn’t seem to be an alternative.”

McGrath is encouraged by the recent resurgence in jobs coming back into the U.S. from overseas, particularly China. “Fortunately for us, a lot of that has been driven by regulatory and documentation issues in the Far East in compliance with some food and beverage, and children’s toy regulations where they were unable to comply,” he explains. “Some of our new customers got nervous and decided they really needed to come back stateside. A company like ours was more than ready for this. With our high-volume model—we have 106 machines and six operators, so we have knocked the labor burden out—coupled with our ad campaign we call ‘Cheaper than China,’ our business has been up significantly over the past few years.

“When customers ask us how we are able to compete with China in this manner, we tell them basically we were downsized before the term was fashionable,” McGrath continues, “and that we always worked toward limiting operators at the presses and automating versus populating the factory with workers. A lot of molders didn’t make that adjustment and found themselves people-intensive, so when the business opportunities presented themselves they didn’t have an opportunity to respond, where we did.”

McGrath is also quick to point out that while Rodon has had the opportunity to seize more business, the company makes sure it stays true to its business model. “We are not doing any hand operations at the press, we are not decorating or bagging by hand,” he says. “We will perform these operations if they can be automated. If not, we will pass on the job because it will increase our labor burden and we would not be operating within our core competency.”

Quality Equals Profit

Allen is confident that Rodon’s business will continue down this profitable path. “We really don’t lose customers,” he affirms. “We hold quality to a very high level, which retains loyal customers. Rodon is proud to manufacture products using the internationally recognized ISO 9001:2008 standard. Adherence to the standard is certified by BSI (British Standards Institute). Some of our products are 100 percent inspected using a KEYENCE Vision Inspection system and parts requiring dimensional checks of a higher level can be inspected on our Mitutoyo QuickVision System.”

Rodon’s tool quality also is excellent, Allen points out. “We manufacture high-quality, stainless steel tools with the highest end mold components in the marketplace,” he notes. “This allows the tooling to run uninterrupted 24/7, thereby maximizing efficiency and assuring part quality as well as on-time delivery. These are all keys to our success—and it is through the efforts of everyone at this company—that we expect this success to continue.”

For more information:

The Rodon Group / (800) 523-8792; (215) 822-5544

sales@rodongroup.com / rodongroup.com

Blog: info.rodongroup.com/

Twitter: twitter.com/#!/rodongroup

Related Content

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreHow to Use Automation to Minimize Mistakes and Speed Mold Build Process

A guide to capturing and reusing company knowledge and experience with software automation.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)