Anyone who designs, builds, runs or repairs injection molds knows the importance of having optimum control over heat profiles to reduce material waste and maintenance downtime due to nozzle leaks or just poorly molded parts.

Eliminating the risks of overheating and leaking is therefore a much sought after objective, and it makes economic sense to consider incorporating internally heated hot runner nozzles or molding machine nozzles into the mold design or production process because they save money.

Figure 1: An internally heated nozzle that leaked, but remains self-contained. Photo Credit, all: Melt Design Inc.

One key reason internally heated nozzles save money is because they are 100% sealed. Plastic material cannot leak out and damage wires in the channels or nearby nozzles; whereas, with traditional externally heated nozzles, leaking and system damage can and does occur.

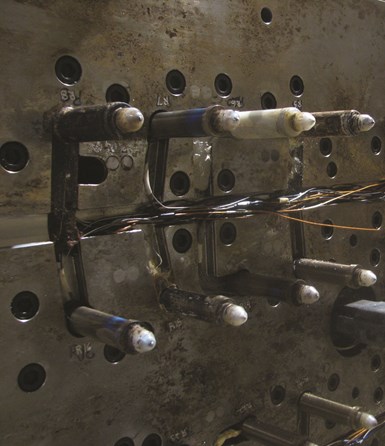

For example, if one externally heated nozzle leaks in a hot runner system, more often than not the leaked plastic will follow the wire channels and flood them, causing all of the nozzles and channels to become one big plastic mess. It can be an expensive repair job if the entire heating system is affected (see Figures 1 and 2).

A mold with an externally heated nozzle that leaked, causing plastic to flood the channels.

In addition, in hot runner systems using internally heated nozzles, spare parts are rarely, if ever, required because the nozzles do not leak. To emphasize this point, a major multinational OEM that manufactures caps and closures has employed more than 200 internally heated, multi-cavity hot runner systems for more than 14 years and, because the company has seen firsthand the benefits of the internally heated nozzle, it does not stock spare parts. That’s true savings.

Because a hot runner system is often a large part of the overall cost of a mold, some people stress about the warranty of the system, but they don’t consider the frequency of burnouts or other issues that can cost dearly in downtime. Utilizing internally heated hot runner nozzles alleviates the stress because they are virtually fail-proof compared to traditional, externally heated systems. They are like an insurance policy against downtime and replacement part costs.

In most cases, internally heated hot runner nozzles can be retrofitted on existing hot runner systems. It should also be noted that they work well with hot halves available on the market that offer the same features.

The Internal Difference

With an externally heated nozzle, the sensitive parts of the heating system — such as the thermocouple, heating coil, sleeve, etc. — are located on the outside of the nozzle body. As the coil is heated, it expands, causing a gap between itself and the nozzle body so that it cannot touch the nozzle body uniformly. Because of this, the coil must be heated at a higher temperature to properly heat the plastic. Not only is there a risk of heating unevenly, but the higher temperature also means there is a risk of overheating and burning out the coil (heater failure).

This is not so with an internally heated nozzle. Because the insulation around the heating wire is solidly compacted to maximum density, it eliminates any air voids around the resistance wire and surrounding nozzle bore. The heater inside the nozzle is an integral part of the body, so it resists burning out and contributes to more efficient heating. How? The heater element is able to run cooler due to the highly dense insulator, which carries away heat produced on the surface of the resistance wire when the heater is energized. So not only does it run more efficiently, it also helps prolong the heater life.

Another notable benefit of internally heated nozzles is the location of the thermocouple. The thermocouple and the heating element are located much closer to the gate, at the end of the nozzle, so they deliver heat at a very precise temperature. The result is a better heat profile and more controlled melt temperature and, therefore, better molded part quality. With externally heated nozzles, the nozzle may be heated properly, but there is a risk that the nozzle tip is not because the thermocouple stops short of the gate. Add to that the structure of the external coil and temperature profiles may be anything but consistent.

Granted, if the heating coil on an externally heated nozzle burns out, it can conveniently be replaced without removing the mold from the press — as long as no leaking has occurred. This is not possible with an internally heated nozzle, but it’s clear the benefits outweigh the slim chance of the heating element burning out, and like other systems, nozzle tips and seals are replaceable at the molding machine.

Two internally heated molding machine nozzles.

Internally Heated Machine Nozzles

Besides the internally heated hot runner nozzle, there is another product available that is just as unique: the internally heated machine nozzle, which shares many of the same features. As shown in Figure 3, the entire unit is fully sealed. The heater and replaceable internal thermocouple is located directly behind the nozzle tip, which ensures an accurate melt temperature reading.

Ease of Maintenance

While there is little, if any, need for replacement parts when using an internally heated hot runner nozzle, in the rare instance that the thermocouple does fail, it can be quickly and easily changed out while the heating element remains intact — definitely a savings in time and cost. This is not possible with some styles of externally heated nozzles, as too often the entire coil must also be replaced.

Summary

Whether one is looking to cut costs, reduce material waste and downtime or produce more quality parts, internally heated hot runner nozzles and machine nozzles offer a clear-cut solution.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRead Next

Internally Heated Hot Runner Nozzles: Leak-Free Performance for More Profitable Production

Case Study, Hot Runners, Packaging

Read MoreHot Runner Temperature Control: A Low-Investment Solution for Challenging Molding

To understand the importance of hot runner controls, you need to examine how they actually control temperature, processing implications and mold design considerations.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More