CT scanning: A Differentiating Factor

NyproMold finds its growth in differentiation—including using CT scanning to look through parts with an accuracy of 5 to 7 microns, obtaining information that can speed the mold manufacturing process.

Computed Tomography also known as CT scanning can help build better molds faster for a lower cost. It is remarkable how big an impact can be realized from an inspection tool that first gets involved once a mold produces a part.

Mold building used to be an art—craftsmanship centered on taking a set of prints for a part and making a tool that would mold that part. Today, we emphasize mold manufacturing, centering around the entire process from concept to completion. This can allow faster time-to-market and more consistent results. Heavy emphasis on up-front engineering helps ensure a more predictable, reliable outcome. Machining at higher speeds with greater precision, reducing polishing and fitting, speeds the actual mold production stage and more quickly completes the physical mold.

The mold isn’t finished until it meets customer approval through rigorous validation. That’s where CT scanning can help reveal a part’s secrets. Not only can you thoroughly inspect a part quickly, but you can also inspect an assembly, and see how parts are interacting. Ultimately, you and your customer get products to the store shelves faster.

Growing from a core of eight employees just 25 years ago, NyproMold of Clinton, MA, is a 150-person precision plastic injection moldmaking firm specializing in medical and packaging molds (its Gurnee, IL location has approximately 30 employees). President Bill Muldoon recognizes that today the market has too little work for the global supply of mold manufacturers. NyproMold finds its growth in differentiation, creating compelling reasons for molders to deal with NyproMold. “Realizing that as a mold manufacturer, NyproMold doesn’t really have its own product, we need to recognize that each customer has different needs like cost, performance or longevity,” says Muldoon. “We need to respond to those needs and make NyproMold their best choice.”

NyproMold has built its organization with systematic heavy investment in human resources and equipment, focusing on their specialty of high precision. Recent acquisitions have included CFD (computational fluid dynamics) and DMLS (direct metal laser sintering). CFD provides detailed analysis of the coolant flow through a mold in the design stage. DMLS is one of several techniques that help NyproMold implement conformal cooling to put cooling flow at precise locations needed for complex contours. Used in tandem, improved cooling helps reduce cycle times and improve part quality.

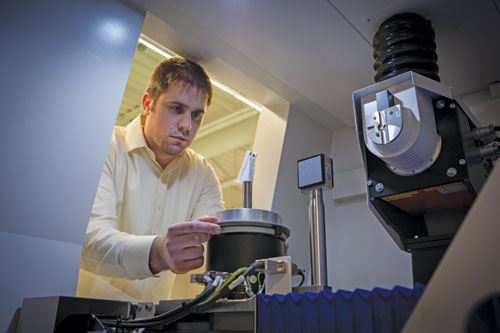

NyproMold’s latest addition is CT scanning. “When we consider investing in equipment, we look at payback as ‘how does it bring value to our customers,’” says Muldoon. “In a world where the mantra is do more with less, cheaper, better and faster, we need to look at the ultimate value of every investment.”

Muldoon compares CT scanning with having x-ray glasses. “Imagine being able to look all through your parts with an accuracy of 5 to 7 microns.” With that incredible promise in mind, let’s look into how it works and the information it provides us to speed our mold manufacturing process.

Many of us have had CT scans for medical reasons. In medicine, the target—you—lie stationary and the scanner moves around you, shooting a series of x-ray images to build a three-dimensional model. In precision industrial CT scanning for small parts, the part is moved in between an x-ray emitter and sensor.

Fixturing a part for scanning is especially easy. The scanner’s software performs part alignment to the desired control surfaces, so all we need to do is set the part in something less dense to support the part through its rotation. Expanded polystyrene (EPS) foam provides a perfect solution that can be fabricated in minutes for just pennies.

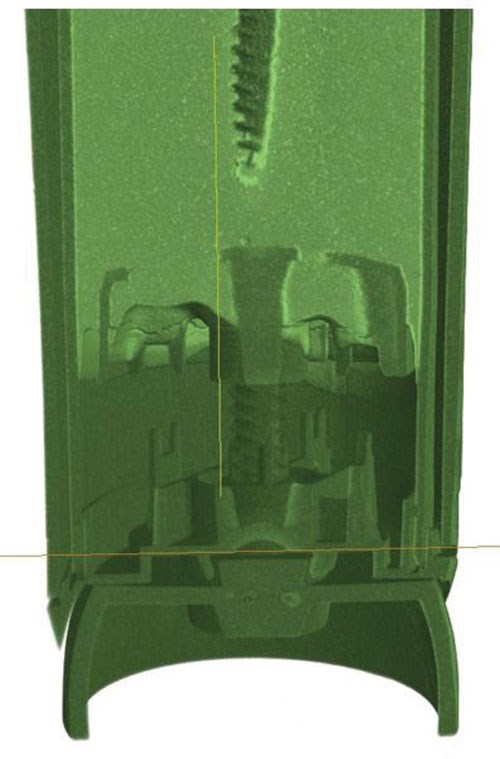

Materials of varying density allow more or less x-ray transmission, triggering greater or lesser detection at the sensor. The initial result is a ghost-like point cloud describing a 3-D part model.

The actual x-ray scan takes about an hour and fifteen minutes, followed by processing into the point cloud, taking another 20 minutes to half hour. All in all, a complete scan with fixturing is normally just under two hours.

Once the initial scan and processing is complete, a variety of reports can be gleaned from additional computer processing that generally takes just minutes. The reports fall into five areas:

1. Part-to-CAD Comparison

2. Assembly Analysis

3. Part-to-Part Comparison

4. Void and Inclusion Analysis

5. Complete Plastic Part Inspection

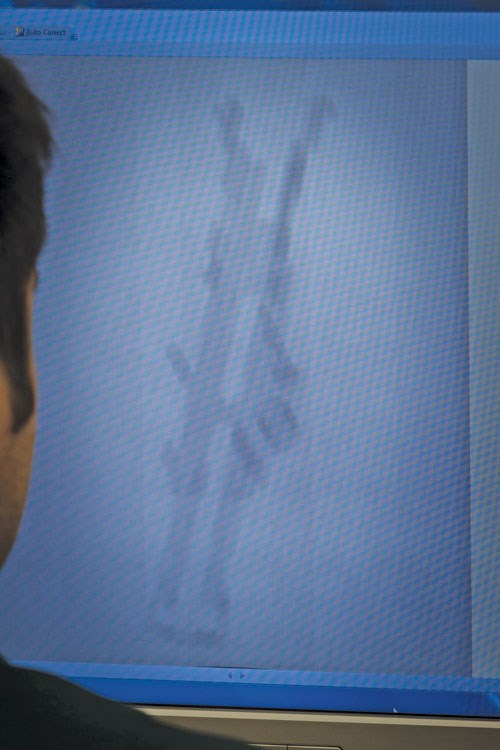

1. Part-to-CAD Comparison is first on our list for good reason. Here’s where we can quickly see deviations between a part and its original design. This visual depiction reveals deviations from design in various colors to make those deviations immediately obvious. The CAD depiction and in-tolerance areas can even be omitted from the display to further emphasize deviations.

2. Assembly Analysis shows multiple parts in one assembly, revealing how they fit and work together. These assemblies may be cross-sectioned along any plane in space to better visualize gaps, distortions, etc. Less dense materials may be omitted from view, to more clearly see small details.

3. Part-to-Part Analysis gives a quick, visual comparison of parts to one another, checking consistency across multiple cavities shot over a time range. The visual is the same as Part-to CAD comparison, but rather than using the CAD model as the control surface, parts are compared with one another. This capability leverages another benefit of CT scanning—that multiple parts up to the capacity of the scanner, may all be set up in one scan for more efficient evaluation.

4. Void and Inclusion Analysis highlights an exciting feature of CT scanning. We aren’t just inspecting the surfaces with CT scanning; we’re actually looking right through a part and verifying its integrity through and through. Void and inclusion analysis gives us a visual depiction as well as statistics of voids (bubbles in the part fill) and inclusions, non-filled or surface distortion issues, even in hidden areas. No other inspection can reveal such useful information without destroying the part and thus introducing distortion errors.

5. Complete Plastic Part Inspection provides a more traditional reporting method. In this case, an inspection report is “designed” or programmed to output results more like traditional metrology, yet in a fraction of the time. Much like programming a CMM, a program is written to collect specific critical data locations and then those locations are retrieved from the scan data and included in a traditional report depicting locations and dimensions.

In addition to complete mold manufacturing, NyproMold is also offering CT scanning and metrology services a la carte for molders and mold manufacturers. As a highly specialized user, their expertise translates to great value for those in the same market. In this way, clients can leverage and get familiar with the benefits of CT scanning without making the financial investment or climbing the learning curve.

With all these impressive benefits, you might wonder why CT scanning isn’t already prolific? CT scanning’s recent introduction in a size and relatively cost-effective package is a big part of the answer. While we might say the cost is relatively cost-effective, that’s a matter of opinion. We might also say it is relatively expensive for most any mold manufacturer.

That leads us back full-circle to Bill Muldoon’s explanation of their drive for differentiation. NyproMold is the first end-user to install CT scanning for their own use in North America. Reiterating his earlier claim, Muldoon repeats “We look at payback as ‘how does it bring value to our customers?’ The payback from CT scanning is about getting better information faster which builds confidence and speeds decision making. Whether it’s getting highly accurate dimensional confirmation on something that is difficult or impossible to measure with conventional means or it’s viewing a precise mechanical interaction between multiple parts to understand if their functioning properly in the right applications CT scanning can bring immense value. It’s often confirmed with the look on the customer’s face when they see the data- the appreciation to finish faster and get better information allowing them to move to the next step in the process of validation.”

Contributor:

Todd Schuett is owner of Creative Technology Corporation (creat.com), which provides photo and video work, specializing in manufacturing. They script, shoot and edit small corporate videos, educational videos, and provide specialized photo and video service for trade publications and advertising.

Related Content

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreUpgrade Your Moldmaking Processes With New Innovations

Read up on new innovations, including modular sorting systems, monitoring platforms for injection molders, indexable milling cutters and more.

Read MoreUsing CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)