January 2008 Issue

January 2008

Features

Featured articles from the January 2008 issue of MoldMaking Technology

How to Evaluate Your Software Reseller

Your CAD/CAM reseller plays an important role in your use of software by offering technical support, answering your questions and making sure you are productive as quickly as possible. Therefore, it’s important to consider the following nine factors when evaluating them before choosing a new CAD/CAM system.

Read More

The Cost of Machine Tool Ownership

How older technology will impede your business in a competitive global market and how to invest properly in moldmaking equipment.

Read More

Complex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

Read More

Courtesy Mold & Tool/REXAM Mold Manufacturing: Change is Good!

Over the past decade this turnkey shop changed ownership and thrives with a focus on high cavitation, tight tolerance molds.

Read More

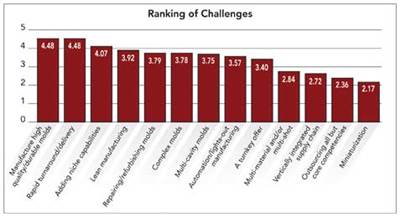

Mold Market Analysis

Report on the challenges and opportunities for moldmakers that lie ahead in 2008.

Read MoreTen Years of Change and Challenge in the Moldmaking Industry

The changes and challenges that AMBA members have seen over the past 10 years have required them to be flexible and meet these changes and challenges head on.

Read More

Commercial Tool & Die: High Quality and Employee Innovation Drive Success

Unique, employee-developed programs tighten this moldmaker’s leadtimes—resulting in high quality tools delivered on time and the MoldMaking Technology 2008 Leadtime Leader Award: Large Shop.

Read More

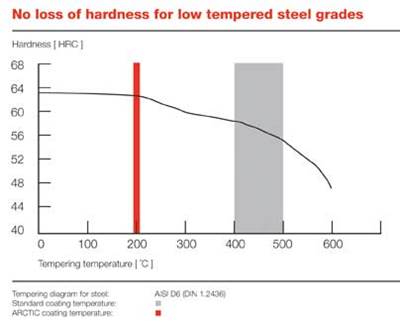

Lower Deposition Temperature PVD Coatings Allow for Greater Choice in Mold Materials

New technology allows for application temperatures as low as 200°C (390°F) with no loss in coating performance.

Read MoreReady-To-Go Molds: Delivering a Fully Validated Mold

The business we all know and love continues to become more challenging on a daily basis.

Read More

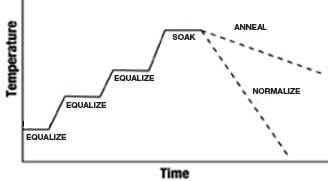

Tool Steel and Heat Treatment, Part 1

An introduction to heat treatment for the moldmaker.

Read More

Laser Systems: Engrave, Texture, Mark, Frost and Smooth with One Tool

By embracing laser machine tools, you can reduce steps in your machining processes, which results in improved productivity, improved quality and increased flexibility.

Read More

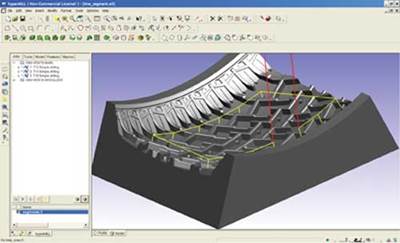

Maximizing Machine Tool Potential with CAM Software

Identifying specific items where CAM software can take advantage of machine capabilities to the benefit of the user and maximize exploitation of milling machine potential.

Read More