BIG KAISER Adds New Inserts to Offerings

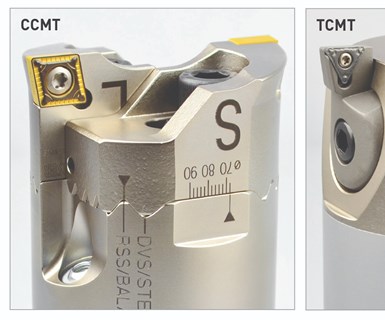

Big Kaiser Precision Tooling is adding more than 30 pressed-geometry carbide inserts for its tools.

Big Kaiser Precision Tooling is adding more than 30 pressed-geometry carbide inserts for its tools. The new insert design is the result of extensive research and testing. The new grades and geometries offer improved chip control due to optimized chip breakers, even when boring gummy materials like low-carbon or stainless steel; improved coatings for increased speed and better wear resistance; more positive cutting geometries to reduce cutting forces, chatter and vibration when used in deep-hole boring operations; and longer tool life.

Big Kaiser offers a range of insert grades and geometries for rough and finish boring, grooving and precision cutting, including indexable inserts. For more information, contact Big Kaiser, Hoffman Estates, IL, at 224-770-2999, e-mail bigkaiser@us.bigkaiser.com or visit www.bigkaiser.com.

Related Content

-

How to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

-

Manifold Blocks for Flexible Cooling Circuits

Hasco’s Z920/ manifold blocks create a centralized inflow/outflow location that enables the use of shorter hoses in mold heating/cooling systems.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.