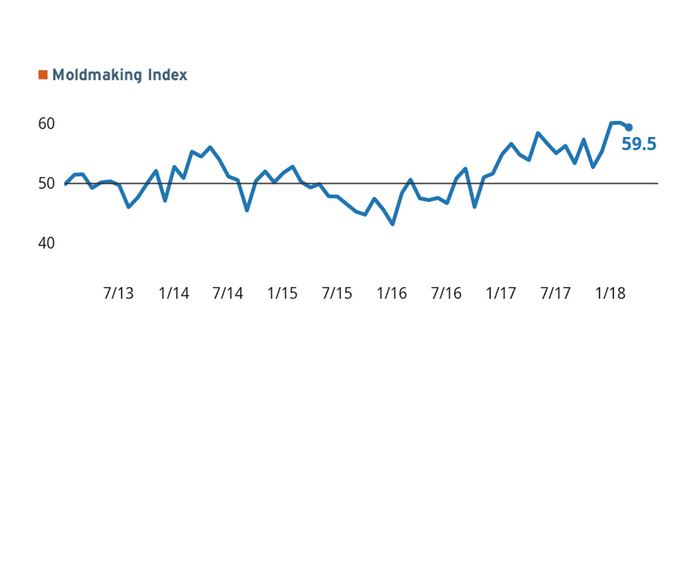

Gardner Business Index: Moldmaking Finishes Best Quarter Ever

New orders growth boosts Moldmaking Index, at 59.5 for March.

Share

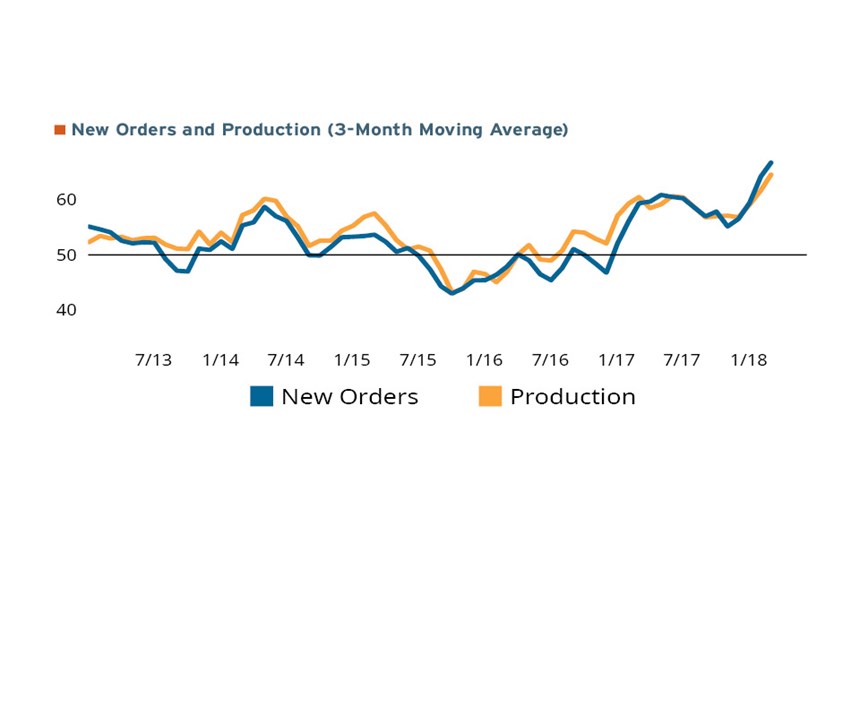

Registering 59.5 for March, the Gardner Business Index (GBI): Moldmaking completed its best quarter ever with an average quarterly reading of 60.0. In comparison to the performance from the same month and quarter a year ago, the Moldmaking Index increased by 8.0 percent and 7.7 percent, respectively. Gardner Intelligence’s review of the underlying data for the month revealed that growth in new orders, production and supplier deliveries boosted the Moldmaking Index. The March reading for supplier deliveries was the second highest reading since 2012. Components like backlog, employment and exports lowered the Moldmaking Index’s average-based calculation. No component of the overall Moldmaking Index contracted for a fourth consecutive month.

March’s notable events included a significant increase in the growth of supplier deliveries and the significant slowing of growth in backlogs. As has been reported previously, the moldmaking industry—along with manufacturing in general—has experienced very significant growth in new orders over the last 18 months. During many of these months, the reported growth of new orders outpaced moldmakers’ ability to raise production, resulting in elevated backlogs. According to the data, supplier deliveries by the fourth quarter of 2017 caught up with the rush of new orders growth that initially took place during the first quarter of 2017. The most recent quarter’s data indicates that suppliers have become much more responsive to needs of moldmakers, and the drop in backlogs to a more typical level is evidence of that responsiveness from suppliers.

March’s data only for custom processors indicated that new orders and production are driving further industry expansion. Unlike the overall Moldmaking Index, strong new orders and weaker supplier deliveries readings in the latest quarter drove backlogs higher.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

.jpg;width=70;height=70;mode=crop)