Videos

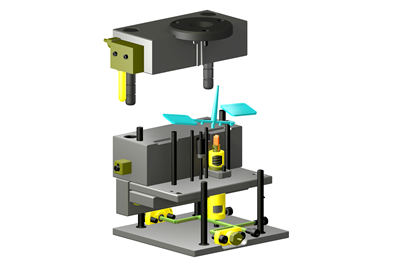

Mold Monitoring System Provides Real-Time Mold Performance Monitoring

Arburg showcases a range of machines highlighting digitalized manufacturing including the Hack Moldlife Sense system, used to detect and notify operators about errors and irregularities in the mold.

WatchMMT Ask the Expert: Hot Runner Benefits and the Fundamentals of Maintenance and Refurbishment

In this next portion of our “Ask the Expert” series, Husky’s Derrick Hennebicque answers some FAQs about the advantages of hot runner systems and refurbishment strategies. This episode is brought to you by Husky, Melt to Mold Precision.

WatchThe MoldMaking Conference: All About Next-Level Mold Building

Here we spotlight the Build block of sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

WatchMMT Ask the Expert: Servo Control and Hot Runner Temperature Controller Best Practices

In this portion of our “Ask the Expert” series, Husky’s Vernon Moss answers some frequently asked questions on servo control and hot runner controllers. This episode is brought to you by Husky, Melt to Mold Precision.

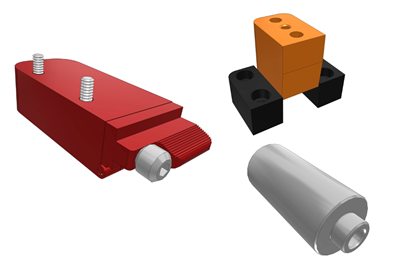

WatchGate Cutting Technology Advances Mold Material Separation

Ermanno Balzi’s latest technology uses the the axial movement of a cutter to optimally separate the molded part from the cold runner during the mold cycle.

WatchMMT Ask the Expert: How to Optimize System and Hot Runner Balance

In the first portion of our “Ask the Expert” series, Husky’s Sheldon Alexander answers some frequently asked questions on the fundamentals of system and hot runner balance and how to overcome challenges. This episode is brought to you by Husky, Melt to Mold Precision.

WatchVIDEO: How to Create an Elite Moldmaking Workforce

Alex Beaumont, Vice President of Beaumont Technologies, shares details about the company’s specialized workforce development program, which is based on individualized training.

WatchThe MoldMaking Conference: All About Next-Level Mold Engineering

The MoldMaking Conference is for the next-level mold manufacturer because moldmaking has moved beyond art and craft to science with technology advancements aimed at engineering and building a better, more cost-effective mold. It is with this focus in mind that we are launching The MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina, under the 4 pillars of MoldMaking Technology—Engineer, Build, Maintain and Manage. Here we spotlight the Engineer block of sessions.

WatchExpansion of Online Moldmaking Catalog Streamlines Mold Component Search and Sourcing

DMS Components has launched a new part number lookup feature and 3D PDF facesheets to improve the online experience for design engineers and purchasing departments when searching for mold components.

WatchVIDEO: Complex Valve-Gate Hot Runner Molds and Processing Reinforced Material Tips

Tony Brodzeller, Technical Sales Director at Mastip talks about its complex 72-drop valve-gate stack mold hot runner system, tips for processing reinforced materials and his perspective on the future of moldmaking.

WatchVIDEO: Molding Simulation Brings the Mold Builder and Molder Together

Mark Solberg, Executive VP of CAE Services and Jason Bonanno, VP – New Business Development of CAE, discuss CAE’s Moldflow analysis services. Learn how to know when your shop needs to outsource or invest in software and the mold builder’s role in using mold analysis software.

WatchMoldMaking Conference: All About Next-Level Mold Manufacturing

Next-level mold manufacturing is dependent upon accurate, repeatable and efficient technologies, processes and talent when it comes to designing, building, maintaining, repairing and managing molds. It is with this focus in mind that we are launching The MoldMaking Conference on November 8-9 in Charlotte, NC.

Watch