Share

Read Next

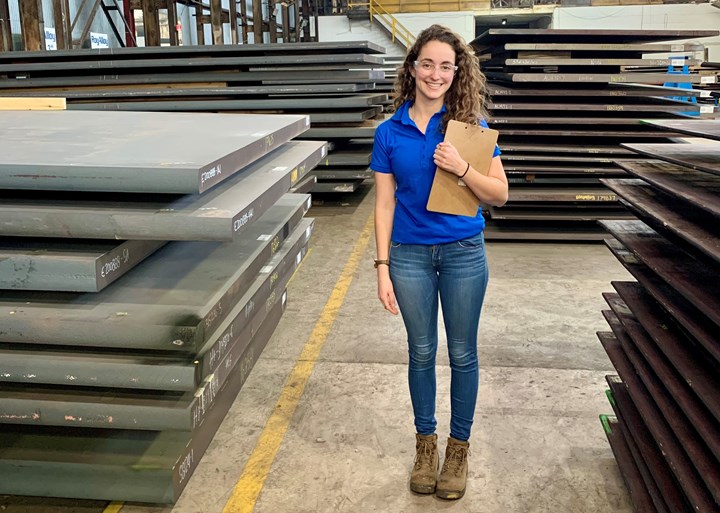

Katherine Pistorius is a full-time project engineer. She is the only female engineer in the company, but that doesn't matter. It's her personality, ambition, humility and enthusiasm that matter. Photo Credit: Edro Specialty Steels.

With a father who practiced finance and a mother practicing law, Katherine Pistorius is the only engineer in her family. She always liked math and science, so her big decision after high school was whether she should pursue mechanical or industrial engineering. Mechanical seemed to offer more methodical desk jobs, and she was looking for more—an environment where she could see the progress her changes would make. So industrial engineering it was. She thought earning her BA in industrial engineering would open doors to consulting work and allow her to travel the world.

It turns out her current reality is not that far off from what she planned.

Finding a Focus

Katherine's first taste of manufacturing happened during her sophomore year of college. She was hired as a manufacturing intern at Schindler Elevator Corporation in Hanover, Pennsylvania. “They just opened a shop that had beautiful machinery and systems. I was in charge of optimizing the safety and SOP documentation. I absolutely loved it,” Pistorius says.

I'd say that “intern work” foreshadowed where Katherine is today. She graduated from Penn State University in 2017 as an industrial engineer and took a year off to determine her path forward. “While working at a restaurant, I told a colleague that I wanted to work for an engineering firm that incorporated travel. She mentioned that her friend, Rob Curran, was a metallurgist working for a steel company and doing a lot of travel. She connected the two of us, Rob set up an interview and the rest is history,” Pistorius says.

Today, Katherine is a full-time project engineer at Edro Specialty Steels Inc. Her home base is Edro’s Conshohocken, Pennsylvania facility, which employs a team of both seasoned and next-generation workers. Katherine is the only female engineer in the company, but that doesn't matter. It’s her personality, ambition, humility and enthusiasm that matter.

All of those qualities help Katherine to take on work with ease. She spends her days putting out fires and identifying areas for improvement. “I'm all about simplification, optimization, and efficiency,” Pistorius says.

Currently, she is managing multiple projects but with a particular focus on the company’s new lean manufacturing initiative. Edro is setting the ground work for an ISO certification in Conshohocken to keep up with the California facility, and Katherine is leading that charge. She handles administration paperwork, such as OSHA and company safety documentation, and she is reworking all administration systems to make them paperless. She is also working on her Six Sigma training, which is new to Edro. She recently acquired her green belt and is working towards her black belt.

“They see me being a Lean Six Sigma representative for all of Edro Specialty Steels Inc.—Philadelphia, Pittsburgh and Chicago. They also offered me project management training, which has led me to a position on the project management board,” Pistorius says.

She is working on methods to go paperless, updating filing systems, training employees and recordkeeping. She is ensuring that everything in those areas is stable. And, of course, she travels (at least she was before COVID-19). She plans to visit the other facilities in Pittsburgh and Chicago to set up the same lean guidelines.

Katherine was also the only North American competitor in a global lean competition hosted by Edro’s parent company.

“Once you have an interest, management and leadership are so supportive. It doesn't matter if your interest emerges within the first two months or the first two years, they let you run with it and support you,” Pistorius says. “For example, the company president gave me the blessing to get my black belt because he likes the fact that I'm giving back to the company and that he sees progress.”

“It's not for the faint of heart, because you create a lot of your career's direction, and leadership sees that."

Traveling to Learn

Landing this job at Edro has fulfilled Katherine’s need for technical work and her desire for travel. “The beauty of my job at Edro is how much you can travel. That has always been my dream, and your first year here, they send you to Austria for a week of preliminary training and to the facility in Germany,” Pistorius says.

Her apprenticeship lasted 18 months, during which she was trained to be a technical sales rep first. “Sales is not my passion but learning inside sales via on-site training and a week in Austria helped me to understand our product line” Pistorius says.

And not only did that immediate travel allow Katherine to experience the company without a predetermined agenda, but it’s the first time she felt like an adult. “You're out of college, you're sent abroad, you don't have a manager with you, and you're away from friends and family,” Pistorius says.

After that initial training, she went to the California facility to work alongside a lean representative, which is when Katherine “fell in love” with cutting waste, process management and efficiency, leading her to green belt training.

She emphasizes how the company embraces initiative, does not set boundaries and avoids micromanagement. She believes strongly that people who come into the Edro environment with no direction and no motivation will not survive.

“You have to take the initiative and create a name for yourself in this company. They have many people in our age group who are very motivated, driven and career-oriented. It’s not for the faint of heart, because you create a lot of your career’s direction, and leadership sees that,” Pistorius says.

She notes that her most inspiring time at Edro so far was the 20 days she spent in Europe for the Bohler training and her visit to the facility in Germany, from which she was tasked with reporting back what she experienced, liked and disliked.

“That trip taught me all that you can accomplish with time, motivation and meticulously perfecting a manufacturing process. I came back to Edro with one goal—to create a manufacturing environment that looks and runs that well—that's my passion,” Pistorius says.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreRead Next

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

Read More30 Under 30 Bonus: Highlighting Additional Next-Generation Moldmaking Professionals

Nominations for MoldMaking Technology’s 2021 30 Under 30 Honors Program surpassed the 30 we were searching for, so here we recognize more worthy under-30 individuals who are making an impact in the mold manufacturing community.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)