Cutting Tools

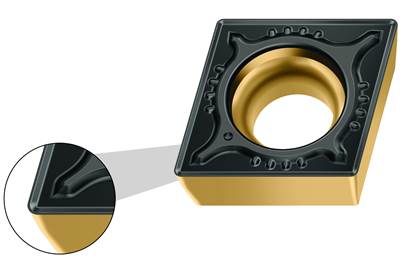

Turning Insert Geometry Delivers Expertise in Machining Medium Steels

The MP6 geometry introduced by Walter USA combines features for efficient chip breakage and a strong cutting edge.

Read MoreTool Caddy Safely Stores Cutting Tools

The Kaiser Manufacturing Tool Caddy makes it convenient for the operator to grab toolholders without any risk of cuts.

WatchEnd Mill Series Committed to High Hardness Steels

OSG USA AE-CR-MS-H end mill and Phoenix PXM-PXSH exchangeable head end mill series can machine steels from 50-70 HRC, a common range seen in moldmaking.

Read MoreMetalworking Commodities for Your Next-Gen Molds

Featured in this month's technology roundup are products, processes and services that revolve around metalworking. Also highlighted is software, automation and more.

Read MorePTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

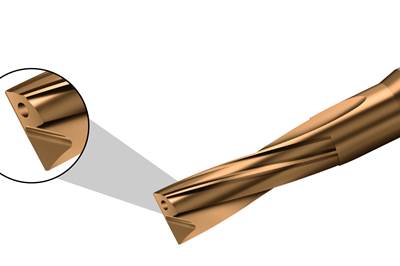

Read MoreNew Generation of Solid Carbide Drills Optimize Inclined or Round Surface Drilling

The Walter DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

Read MoreCarbide Micro Drills Capture Precise Holemaking for Mold and Die Making Requirements

The DB131/DB133 Supreme solid carbide micro drills from Walter USA now come with internal and external coolant capability.

Read MoreMulti-Row Thread Mill Delivers Heightened Mold Machining Productivity, Accuracy

Walter USA solid carbide thread mills provide users with a high level of process reliability, easy handling and a low cost per thread.

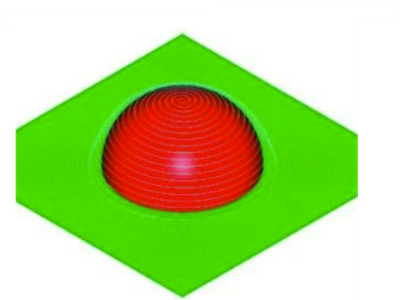

Read MoreMicro-Diameter End Mill Series Reduces Cutting Time, Enhances Finishing for Ultra-Precision Moldmaking

Towa Corp. features CBN and proprietary-coated solid carbide end mills that feature high accuracy, optimized sharpness and wear resistance and ensure long tool life.

Read More

.png;maxWidth=300;quality=90)