Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Share

Leading mold builders employ innovative technology and business strategies to stay competitive and to continually serve their customers better. Photo Credit: Ameritech Die & Mold.

MoldMaking Technology has always featured mold builders who are doing amazing things in customer satisfaction, workforce development, industry involvement, continual improvement, business growth and technology deployment, so I thought why not bring together five exceptional mold builders for a discussion about ways to improve efficiencies with regards to technology, workforce development and business management?

The participants in this discussion are:

-

Don Dumoulin, CEO/Owner, Precise Tooling Solutions—our 2020 Leadtime Leader Winner in Columbus, Indiana, where a 30,000-square-feet-facility houses a 33-person workforce who manufacture plastic injection molds for the automotive and consumer segments. This shop also has mold repair and CNC machining business units and a line of branded ergonomic machine bases and manufacturing tables.

-

Carl Jacobsen, Estimator/Tooling Engineer, M&M Tool and Mold—a 25-person mold-building shop in Green Bay, Wisconsin, specializing in small- to medium-sized injection molds for the medical, automotive, consumer products, recreational, agricultural, construction and appliance markets.

-

Brian Dippel, Operations Manager, X-Cell Tool and Mold—a 55-person tool shop in Fairview, Pennsylvania, focused primarily on molds for the medical and consumer products industries.

-

Mark Rotman, Project Manager, Ameritech Die & Mold—a 35-person mold builder in Morrisville, North Carolina, specializing in medium- to small-sized injection molds for the automotive and appliance industries.

-

Tim Galbraith, Sales Manager, Cavalier Tool & Manufacturing—a 160-person company headquartered in Windsor, Canada (but represented across two continents), specializing in medium to very large plastic injection molds.

Following is the Q&A from our discussion.

How do you create and maintain an employee-centered culture?

Dumoulin: An employee-centric culture is all about transparency, and the best way to do that is to share everything. Every quarter we get the entire team together, and I walk through every line of the financial statement in an effort to give them a deeper understanding of what our business looks like, projected business levels, customer requests, etc. This helps people buy into the workload and the company's growth and profitability.

Jacobsen: We work very heavily with employee involvement in the process. They are involved in design reviews, so they gain some ownership of a project. We also stress accountability for each employee on a job. Every employee has real-time access to data showing them how much has been spent from the budget for that mold.

Dippel: Keeping the employees informed. We manage by walking around and checking in with everyone. We also have monthly, company-wide meetings to review new orders, forecast upcoming business, etc., so people can plan both their jobs and their personal lives. We like employees to have a sense of ownership, so the more information, the better.

We believe in servant leadership. It is management's responsibility to make sure each employee has what they need to be successful.

Rotman: We believe in servant leadership. It is management's responsibility to make sure each employee has what they need to be successful. If they don't have the right tools in their hands, we can't expect them to be successful.

Also, we make sure that everyone has a voice no matter how much or how little experience they may have. We believe new ideas come from a fresh set of eyes.

Galbraith: Communication and transparency up and down are essential. Every decision that the management team takes on must consider the impact on the employees—because a decision may not always be great for every employee. Today, you must have a culture that considers those impacts and then communicates them appropriately. Make sure every employee understands why you made a decision and listen to what they have to say.

Continuous improvement is a fundamental goal at X-Cell Tool and Mold. Members of the management team conduct a weekly meeting to discuss work in progress, any challenges and expectations. Photo Credit: X-Cell Tool and Mold

What is the key to your training strategy and who champions this effort?

Domoulin: The head of our manufacturing organization is responsible for training across the organization, and our training philosophy is hands-on. Our young people are paired with more senior people, and they learn on the job. We don't have the luxury of putting people in classrooms for four weeks at a time. The vast majority of our training is on a job or on a project. We promote learning by doing.

Jacobsen: We run a pull-oriented training strategy so that the employees know where they need to go to move up to the next level. They request the training when it fits their schedule. For example, if they have a new baby, perhaps they will not be interested in attending training at a particular time. Our employees champion their own training.

When we train internally, we use a trainer/trainee approach. When we need new system training or something across the board, we generally run a lunch-and-learn session.

Dippel: In terms of training new moldmakers or new designers, we worked with the state of Pennsylvania to tailor the apprenticeship program more towards our needs—the types of equipment we use and the type of operations we perform.

It's actually beginning to pay dividends because it's happening out on the floor where we are using our own criteria to train our people. Then, when they are finished, they receive a state-issued apprenticeship card.

We are all challenged and charged with knowing the needs of our team members and planning the appropriate training. To that end, we use training as an incentive.

Rotman: We put focus on training why, instead of just how. As we bring in young apprentices, we teach them to troubleshoot with a ‘why’ mentality, instead of a buy-the-book, step-by-step approach. Our champions for this effort come from a pool of knowledge that involves everyone over many years of experience.

Not everyone is a gifted teacher, so a few employees with the gift of teaching who can explain concepts clearly and easily instruct students and train apprentices. They are mentors.

We also have a few employees who have championed investigating new procedures, which then enter into the pool of training and get handed to the mentors who will teach it to the new employees.

Galbraith: The management team and employees all play a role in human resources. We are all challenged and charged with knowing the needs of our team members and planning the appropriate training.

To that end, we use training as an incentive. For example, if an employee shows that he or she is willing to work extra, we'll send them to Dale Carnegie Training.

We also offer sensitivity training for management on how to manage the new generation of workers.

Cavalier Tool & Manufacturing’s Process Engineer Jeff Caruanna manages the shop's ERP system and monitors all manufacturing operations to optimally schedule the shop. He coordinates all material and component purchasing through BOM.

Photo Credit: Cavalier Tool & Manufacturing

What are your top technology investments/recommendations, and why?

Jacobsen: We added a dedicated quality control lab with a dedicated CMM machine, which gives us the ability to document critical steel before shipping and required grooming changes, and to measure steel before and after.

Our second key technology is an electrode machining and an inspection cell with an integrated CMM. We confirm each electrode meets inspection. We don't waste time cutting a full set of electrodes. So, if one fails, it stops there and moves onto the next set of electrodes. Our operator for this cell has remote monitoring capabilities to run the cell lights out from home.

A dedicated quality control lab with a dedicated CMM machine allows the M&M Tool and Mold team to document critical steel before shipping. Photo Credit: M&M Tool and Mold

We did leave a visual inspection step to move electrodes into the tool changers on our EDM machines to make sure there is no chip in a corner or a defect that's not on an inspection point on a CMM.

Our in-house laser welder is another vital investment. It has reduced lead times for any engineering change or repair job.

We are taking delivery of a new sinker EDM to power up the electrode production portion of the shop.

It's not only about monitoring the time that you’re running, it's also essential to monitor the time that you're not running.

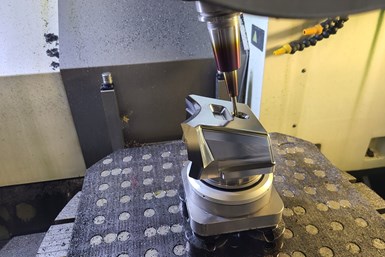

X-Cell Tool and Mold’s Yasda five-axis machine technology and automation have helped the shop to grow its hard milling capabilities and optimize its finish machining operations. Photo Credit: X-Cell Tool and Mold.

Dippel: Our Yasda hard milling cell, and our robotics and palletization are our top technology investments because it's not only about monitoring the time that you're running, it's also essential to monitor the time that you're not running. For example, the time it takes to tear down and set up.

Our CMM and quality lab with a new Zeiss has also been an important investment. Our operator for this equipment has reduced the number of people we need in quality to get the job done. This technology has given our toolmakers out on the shop floor more confidence and trust in his measurements.

Dumoulin: Our ERP system has allowed us to have one record of everything we're doing in the shop, which has saved a massive amount of time and gets us the best records possible. Next is the relationship management software we use with all of our customers. It's a product called HubSpot. We use this for all of our data, communications and quotes.

In terms of machining technology, we spent close to a million dollars a couple of years ago buying a five-axis Roeder.

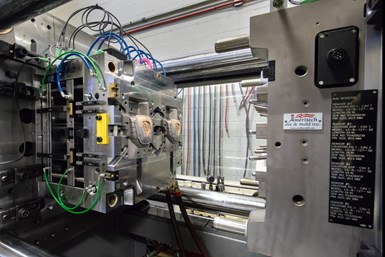

Ameritech Die & Mold continually invests in the latest high-performance machinery and tooling to ensure that its team is equipped with the latest technology for optimal results. Photo credit: Ameritech Die & Mold.

Ameritech Die & Mold continually invests in the latest high-performance machinery and tooling to ensure that its team is equipped with the latest technology for optimal results. Photo credit: Ameritech Die & Mold.Rotman: Our five-axis machine tools have given us the ability to reduce setups, and to reach areas in the cavity that would traditionally need tool extensions. This technology has also helped with rigidity, and reaching areas that we would typically need to put in an EDM.

Next is mold-filling simulation software. It has helped streamline the mold design process and identify pitfalls or possible issues before they have a chance to pop up.

Last is our apprenticeship program. It takes a lot of time, effort and resources to run an apprenticeship program to develop our employees in-house.

Galbraith: We love our five-axis and sophisticated equipment, but I need to call out our ERP. We did a reimplementation of our ERP system, and wrote an interface that allows access to the internal data. This investment has gone a long way in allowing us to drill down in our processes and improve our efficiency.

Next is our simulation software. Our design department runs all of our tooling through their simulation software, looking for crashes, possible interferences, molding issues, etc.

Last but not least is automating our electrode manufacturing with palletization.

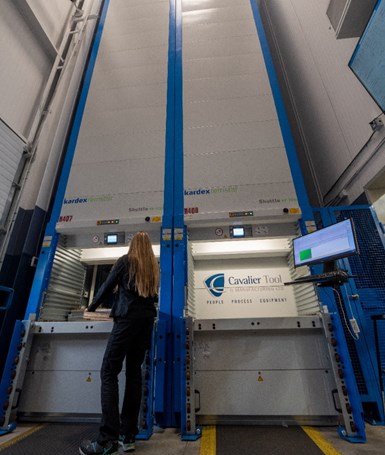

The one side of Cavalier Tool & Manufacturing’s automated storage and retrieval system is supplier owned inventory and the other houses job boxes. The Cavalier team member pulls from inventory to load the job box. She will combine nonstock receivables with inventoried components to completely stock and store the component boxes. When core, cavity and plates are complete, the toolmaker requisitions the appropriate box and it is delivered to the assembly area with all components required to assemble the tool.

Photo Credit: Cavalier Tool & Manufacturing

What is your latest process improvement?

Rotman: Our latest process improvement has been scheduling. We've recently updated to an online scheduling software, and it's improved communication and our ability to be thorough as we work on jobs.

Dippel: We are looking at putting robots on things that we normally weren't thinking about—for example, on our lathes and five-axis machines.

Jacobsen: Implementing an E2 ERP system and working through developing the necessary reports and meaningful formats.

Galbraith: Our automated storage and retrieval system. We amalgamated all of our stores throughout the building into an automated vertical storage unit. Right next to that we have our job boxes in a vertical storage unit, so they are not taking up a lot of floor space. These are pre-populated with our inventory, so when a mold enters the assembly stage, the moldmaker requests his job box and it comes to him fully stocked. All of this is much better than running around to different storage facilities.

Another surprising improvement is the work-from-home protocol that COVID-19 has introduced. We have been surprised that we are more productive working from home than we were working from the office.

Dumoulin: Tying all of our systems together—getting E2 to work with HubSpot—to track a quote throughout the system and then track the financial impact. We manage about 95% of the shop paperless. It's all automated, the machines are attached to it. We know full profitability from start to finish on a job and where a job is at all times. It makes the whole concept of project folders and project paperwork nonexistent.

How do you measure success/metrics?

Rotman: We pay a lot of attention to job costing to ensure that we're estimating costs and meeting estimates, identifying gaps and/or making advancements on what we are estimating. We want to sharpen our estimating skills and ensure on the back end that we're meeting what we are selling. Our biggest measure of success is how we follow up with estimating and keep track of it on the back end, then comparing the two. Also, we’re always looking for opportunities for improvement.

Ameritech Die & Mold applied lean manufacturing principles to every phase in the production of new tools and employs project managers to act as the critical link between each customer and all facets of its manufacturing process. Photo Credit: Ameritech Die & Mold

Jacobsen: We track everything either in real-time or within a 24-hour report that is shared with the shop. For example, hours quoted by hours charged. Anyone can use their laptop to log into a job and find out exactly where they are—actual versus quote by phase code—and make necessary adjustments.

Galbraith: The ultimate metric is net profit at the end of the fiscal year. However, in order to reach that goal you have to monitor everything—including spindle utilization, EDM utilization, cutter efficiencies and even social media impressions. Every department gets its own set of metrics by which they govern themselves and report back to the management team at the end of the year.

We also measure employee satisfaction by providing a good work environment. We look at turnover and sick calls, for example, to assess how happy our team members are.

Dippel: We monitor everything to help determine how much we're making on a job. For example, each week during one of our daily management morning meetings, we run through all of jobs on the ERP system. This shows us where we're sitting currently. We also do a first-off inspection and monitor on-time deliveries.

It is all about little wins. You have to make a lot of little ones to make the big ones.

Dumoulin: Profitability is the ultimate measure. We use a balanced scorecard that has nine different criteria against which we measure—everything from profitability, to employee retention, to on-time delivery. It is all about little wins. You have to make a lot of little ones to make the big ones.

How do you stay competitive or take advantage of new business opportunities?

Jacobsen: Communication is of utmost importance with a potential new customer. You have to be honest about what you can and cannot do and stand behind what you build. As far as internally, we do a post-build Team Review as well as a post-build Management Review that looks at timeliness and customer satisfaction.

We want to go to the next level. We want to be a $10-million company, so we now look to see what the $10 million shops are doing when it comes to a web presence and a social media strategy.

We also now look beyond our local area for business too. COVID-19 showed us there is opportunity beyond our traditional supply chain, partners and customer base.

Rotman: We constantly monitor for continuous improvement to identify areas in which we can better serve our customers. Also, we want to make sure that our customers are successful, which means we need to have close relationships. Ultimately, their success earns us new business.

Galbraith: Meeting customer needs is the best way to stay competitive, but especially during this time we have to be cognizant of reinventing ourselves. It's not good enough to continue doing what you've always done. For example, since we can't get on the road to meet with customers, we're working with our sales group on virtual selling. It's all about staying on top of new trends and analyzing what's coming next, being prepared.

We opened a second design and engineering office in India to help solve our design and engineering bottleneck (running two shifts to take advantage of the time difference). We also merged with Mold Services International (MSI, Ontario, Canada) to continues our momentum with increased capacity in gundrilling, EDM, plate milling, large roughing, large five-axis and toolmaking—all the things we used to outsource. This increased our capacity by 25%. We are currently hiring across the board—designers, toolmakers, machinists, office staff.

We have taken on social media marketing to get the word out. We hired outside help to keep us active. We use both a Cavalier persona as well as individual team member’s personas.

We are also seeking opportunities where they are not waiting for the old school to come back, such as virtual trade shows.

Meeting customer needs is the best way to stay competitive, but especially during this time, we have to be cognizant of reinventing ourselves.

Dippel: Customer satisfaction is number one. We assign a project manager and they are in tune with everything that the customer wants, needs and desires.

Dumoulin: We spend an enormous amount of time doing customer satisfaction surveys twice a year. We've done it now for seven years. We have a really strong understanding of our customers’ wants and expectations, which changes every year. Sometimes in a relationship, you have to understand whether you're pulling your end or if the customer is not the right customer for you.

Related Content

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

-

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Related Content

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreRead Next

A Technical and Business Approach to Moldmaking Increases Growth Opportunities

Next-generation ownership at Kingson Mold and Machine changes culture to deliver optimized, definable and repeatable productivity solutions.

Read MoreTaking Care of the People Side of an Acquisition

Focusing on the human side of the business—employee health, safety, success and growth—is the only way to satisfy both the buyer and seller.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More_970x90 3.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)