Using Nontraditional Technology

MoldMaking Technology editorial advisory board (EAB) member Gabe Meldrum of CIE Century Plastics Inc. shares his take on finding and using new technologies to grow a business, such as waterjets and additive manufacturing.

Gabe Meldrum, MMT EAB member and a plant manager at CIE Century Plastics Inc., shares one of his top priorities: finding new and better ways of doing things. Gabe has been very involved with researching new or nontraditional technologies and processes to help the company grow.

If you are still making molds as you did 10 years ago, your shop is going to find it hard to compete. New and different approaches to manufacturing are vital for growth. Finding the appropriate technology is the first step. The ultimate considerations are speed and cost. Is this new process or technology faster? Is it less expensive? Answering those questions requires research and a deep dive into the specifics of a new product, process or piece of equipment. It also requires sharing that information with coworkers to gain their buy-in. The next step is determining the best way to implement that process or technology into the current way of doing things.

If you are still making molds as you did 10 years ago, your shop is going to find it hard to compete.

For example, IMC’s waterjet process. It all started with a revelation that there must be a faster and better way to manufacture 2D components. Machinists were spending a lot of time on the CNC machines cutting 2D shapes with very generous tolerances, instead of cutting 3D contours on these large expensive mills. As an alternative, the company decided to outsource flame-cutting or burnouts. However, when the workpiece returned to the shop, it had a very hard, nasty scale left behind from the flame, which needed to be machined off anyway. This made the process expensive and slow. IMC then investigated and invested in a waterjet machine, which is faster, provides a clean, straight finish and does not add extra stress on the material being cut. Plus, with a waterjet, a shop can keep the slug (or scrap) and reuse it rather than recycling chips from a mill. Today, IMC continues to find ways to use its waterjet machine.

Another nontraditional process worth investigating is additive manufacturing. This technology is on the rise and will eventually make its way into every mold shop. CNC toolpaths and CAD are other great examples, which have the support of software developers who spend a lot of time and money to make processes faster and better. (A note of caution: if you are not paying the software maintenance fee and using the advancements as they come out, you will be left behind.) Cutting tools also are evolving as new coatings and geometries are developed to improve performance.

The key to finding a new or nontraditional technology is maintaining an open mind, involving the team by asking questions and not dismissing an idea because of the person who offered it (even a floor sweeper can have a great idea). Never stop improving. Once you think you are the best or that there is nothing better you could be doing, your neighbor will come by and eat your lunch.

Once you think you are the best or that there is nothing better you could be doing, your neighbor will come by and eat your lunch.

Related Content

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreMMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

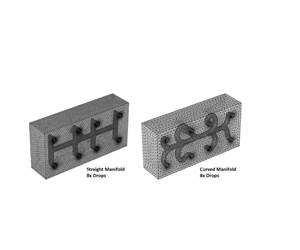

Read MoreGuidelines for Advanced Hot Runner Manifold Channel Design

Recent simulation research highlights the difference between a drilled, straight manifold channel design and a curved channel design produced via additive manufacturing.

Read MoreRead Next

Ballscrew Inspection Considerations

Ballscrews must be inspected for diameter, pitch, lead angle and potential drunkenness to avoid wear and to achieve the necessary tolerances and surface finishes in mold work.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)