Tooling for Closed-Molded, Low-Pressure Injection Molding Reduces Costs and Cycle Time

Floating mold technology, developed, commercialized and patented by VEC Technology, L.L.C. (Greenville, PA)—a complete systems solution.

Floating mold technology, developed, commercialized and patented by VEC Technology, L.L.C. (Greenville, PA)—a complete systems solution approach provider to the composite mold-ing industry including patterns, molds, part manufacturing and turnkey VEC molding systems incorporating floating mold technology—is a new type of tooling for closed-molded, low-pressure injection molding. According to VEC Technology Vice President of Sales and Marketing Ray Fundora, the tooling is based on the fundamental principle that fluids such as water are non-compressible in the pressure ranges used in closed molding.

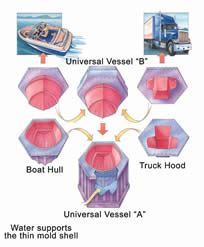

The benefits of using this technology include: reduced tooling cost, reduced cycle times, increased speed-to-market, and increased molding flexibility and performance. Applications include hoods for earth moving and farming equipment, personal watercrafts, golf cart hoods, underground trenches and sumps, structural and flotation foam structures, institutional furniture, boat hulls, decks, and other marine applications.

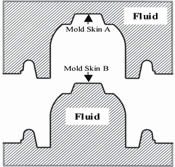

Floating mold components consist of mold skins, attachment flanges, universal vessels and a non-compressible liquid. The construction begins with a master model that is used to create the two molding surfaces (mold skins). One female mold skin (side A) and one male side (side B) are designed to create the proper cavity size between them. Special attachment flanges and all necessary closed-molding hardware are bonded in the mold skins at this time. Then, a set of universal vessels is created—one for the male half and one for the female half of the mold. The universal vessels are outfitted with special attachment flanges, and each mold skin is attached to its own universal vessel with a custom flange—creating an airtight seal between the vessel and the skin.

Next, the two assembled mold halves are filled with water or any non-compressible fluid, and all air is purged from the interior of both vessels through a system the company developed. “Due to the non-compressibility of the fluid, the mold is now a rigid hydraulic system,” Fundora points out. “Any forces exerted on the skin such as internal injection pressures are now transferred through the fluid to the exterior pressure vessel. The universal vessels are designed to handle the maximum potential pressure generated from the injection process. At this point, the mold is ready to make parts. The two assembled mold halves are placed in a lifting frame, which will allow the tool to be opened and closed. Once the mold halves are closed, the injection process is started.”

Since the mold is fluid filled, it has excellent thermal conductivity, which allows for improved temperature control of the mold surface, Fundora adds, and results in reduced cycle time and improved cosmetics. Additionally, the universal vessels incorporate an internal Smart System to monitor pressures and temperatures throughout the molding cycle. “These response systems are designed to close the loop between the injection equipment and the floating mold,” Fundora states. “It allows injection profiles to be adjusted dynamically based on actual mold condition and parameters; therefore, optimizing the injection process. These features result in greater part-to-part constancy, reduced cycle time and improved cosmetics.”

Floating mold tooling life is based on the materials used to manufacture the mold skins. Mold skins can be manufactured using various materials, including chopped fiberglass skins for prototypes and low annual volume; mats, fabrics and roving reinforced for low-to-mid annual volume; and cast aluminum for high annual volume. Fundora notes that minor part design changes can be easily incorporated into the mold skins; and major part design changes can be accomplished through new skins. The attachment flanges and the universal vessels can be re-used—further reducing the cost of new tooling.

Related Content

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreRead Next

Changeable Mold Base Offers Flexibility, Productivity While Reducing Tooling Costs

A mold base has been designed that provides faster production changeovers.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)