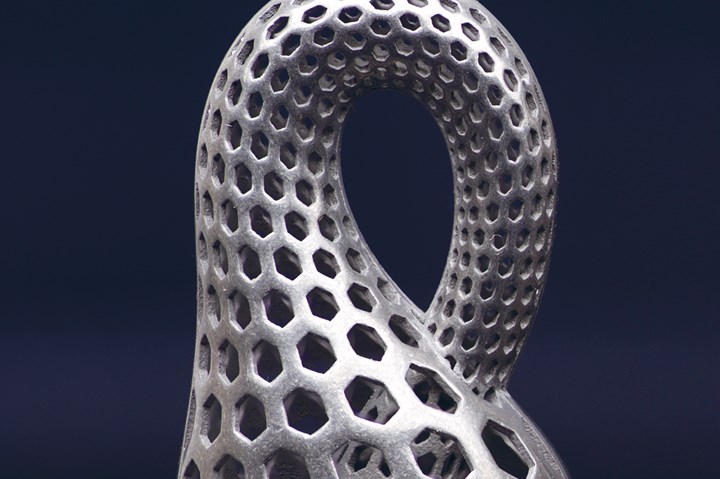

Tool Steel Alloy For Binder Jetting Delivers High Hardness and Strength

Digital Metal and its DM D2 tool steel alloy for AM can be heat treated to high hardness and compressive strength. Offers versatility and high wear resistance.

Photo Credit: Digital Metal

To meet the 3D metal printing market and its use of binder jetting technology—which uses an industrial printhead to selectively deposits a liquid binding agent onto a thin layer of powder particles—Digital Metal has expanded its portfolio to include DM D2, a tool steel alloy that is said to provide an effective combination of abrasive wear resistance and toughness. DM D2 is suitable for a wide range of applications, but most commonly for cutting and deformation tools.

According to Digital Metal, DM D2 is a versatile high-carbon, high-chromium D2 tool steel alloy that can be heat treated to high hardness and compressive strength. Hard enough to suit the task of stamping and forming other metals without losing its shape, it offers high wear resistance and is suitable in cold work applications that require sharp edges and abrasion resistance.

The steel alloy also delivers excellent surface finish and flexibility. The company adds that it is very stable during heat treatments, which allows for tailoring of the final material properties through various heat treatments after sintering.

Related Content

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.