Software Features Automation Functionality

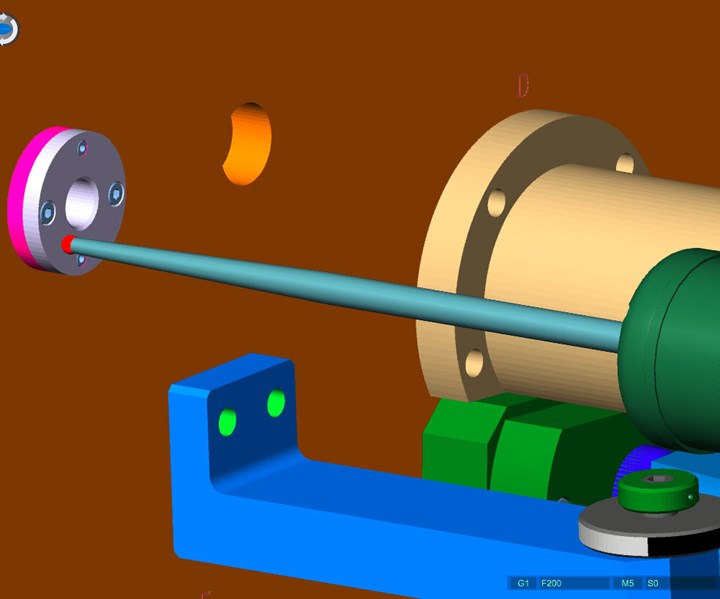

The NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers.

#industry40

NCSIMUL from Hexagon Manufacturing Intelligence is designed to streamline CNC programming and increase shop-floor flexibility. Based on client-server scheduling architecture, the NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers. A dedicated graphical user interface now allows tasks such as simulation, cut analysis and 3D movies to be performed on any device. This enables users to follow the status of jobs and receive notifications when they are complete.

The NCSIMUL Automation Module provides a number of significant benefits, including a guarantee that 100 percent of the program sent to the shop floor is validated by simulation. The system enables users to implement their own automation rules according to constraints and production priorities, and tasks are featured in a command file that can be easily customized to include user-specified parameters. This delivers additional assurance that program verification and simulation accurately follow requirements.

RELATED CONTENT

-

7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.