Pallet Changer Increases Productivity of Grinder by Improving Spindle Runtime

The CVG series vertical universal cylindrical grinding machine parts can be loaded onto a fixture outside of the machine while the machine is running.

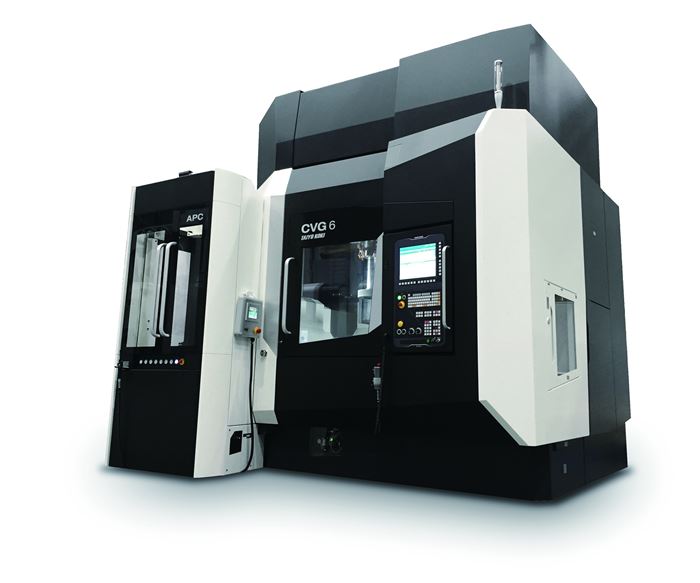

The CVG series vertical universal cylindrical grinding machine with an optional pallet changer from Taiyo Koki Grinding Machine Company, a DMG MORI company, is available in three different part-swing diameter sizes: 25.5", 37.5" and 53". The machine is able to grind OD/ID and faces all-in-one part chucking with guaranteed machine roundness accuracy of less than .00004". The machine has opposing twin wheel spindles. One is a larger, heavy-duty spindle dedicated to OD and face grinding that uses a 14" diameter wheel, and the other spindle is used primarily for ID and face grinding. Both grinding spindles are high-frequency.

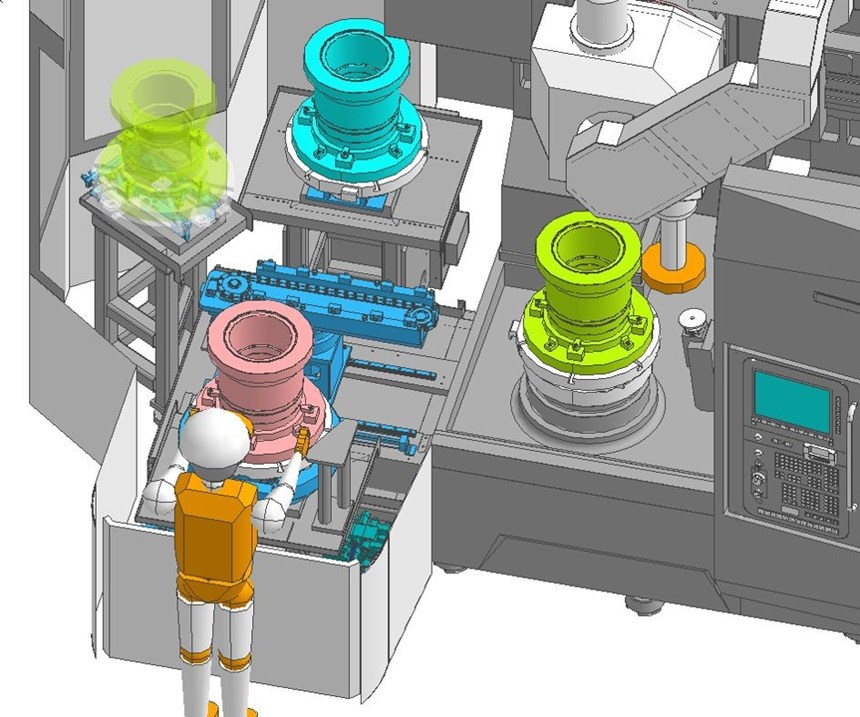

The optional pallet changer increases productivity by improving the spindle runtime. Parts can be loaded onto a fixture outside of the machine while the machine is running. Machinists can add an available part-clocking station with a dummy spindle, which enables parts to be rotated and “clocked-in” at the part-loading station. Machinists can run multiple jobs simultaneously by registering and setting different workpieces outside of the machine, which automatically selects programs and tooling for a different workpiece. Being able to run different jobs through the machine at the same time improves productivity and throughput.

Related Content

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)