MoldMaking Technology Noteworthy News, Jan. 28, 2021

The latest technology from Walter USA, YG-1 Tool, Burger & Brown Engineering, and HASCO America

Share

Vibration-Damping Adaptor Yields Vibration-Free Milling for Long Tools

Patented Accure·tec AC001 adaptor from Walter offers industries three times the process reliability and tool life. Ideally suited for the Walter Xtra-Tec XT milling cutter range.

Photo Credit: Walter USA

Walter USA showcases the Accure·tec AC001 vibration damping adaptor, a patented damping system for vibration-free milling when using long tools. Made specifically for shell mill mount milling cutters, the system delivers increased productivity and stability along with greater surface quality, improved tool and spindle life, and is ideal for deep pocket milling in operations at depths of up to 4xD.

The vibration damping is provided by an axially- and radially-flexible position damper element which is preset at the factory for immediate tool use. Ideally suited for the Walter Xtra-Tec XT milling cutter range (more on this range: Face Milling Cutter for Maximum Reliability and Shoulder Milling Cutter Handles Versatile Operations and Materials), Walter says the adaptors offer high industry versatility, and can be applied to the aerospace, automotive, energy, die/mold and general metalworking industries. Users are able to benefit from both the vibration damping and a system with low noise levels.

According to Walter, Accure·tec delivers its advantages of longer tool life, higher productivity and greater process reliability at depths of cut up to three times that obtained with conventional methods. Internal coolant further optimizes chip removal. Walter offers Accure·tec with all popular machine interfaces: Walter Capto, HSK/HSK-T, ISO, MAS-BT, CAT and parallel shank.

In addition, Walter offers new sizes to its existing Accure∙tec A3000 boring bar line, which incorporates the same technology as the AC001 vibration free long milling tool adaptor. The A3000 is now available in 1.00-in. and 25-mm diameters in steel, as well as 1.00-1.25-in. diameters in carbide at 10xDc. The product extension also includes Capto C4, C5 connections in a 25-mm diameter along with HSK-T63 connections in 25-, 32-, 40-, 50-mm diameters.

Exchangeable Drills and Tool Steel Holders For Faster Changeovers, Longer Insert life

The i-ONE line from YG-1 offers micro-grain carbide drill inserts, and premium tool steel holders with coolant channels that resist corrosion and wear and ensure body clearance.

Photo Credit: YG-1

Coating advances and optimized designs take tool life and changeover speed to new highs with YG-1’s new i-ONE system of exchangeable micro-grain carbide drill inserts and premium tool steel holders with coolant channels for maximized machining productivity and profitability.

According to Steve Pilger, product manager, Holemaking, the i-ONE line offers the advantage of a solid carbide drill combined with the flexibility of steel bodies via inserts that combine a new multilayered H-coating and optimized cutting angles with tool steel holders that retain Torx Plus clamping stability. These attributes and more, says Pilger, ensure i-ONE drills last longer, and that the insert changeover process has been made foolproof and worry-free.

i-ONE drill inserts offer additional advancements including:

- Micro-grain carbide core for exceptional strength

- Advanced multilayered H-coating for excellent hot hardness, minimal wear

- Optimized point geometry for centering and smoother cutting

- Ground negative land on cutting edge for extended cutting life

The system’s nickel-plated tool steel holder features:

- Premium tool steel shaft optimized to resist corrosion and wear and ensure body clearance

- Optimized flute shape for smooth chip evacuation

- Torx Plus Screw for reliable insert seating and stability at the full range of speeds

- Coolant holes to dissipate heat in and evacuate chips from the cutting zone

i-ONE drills come in various insert sizes, and tool steel holders are available in 3xD, 5xD and 8xD depths and in ODs from 0.393 in. to 1.328 in. and Ø10 mm to Ø33.73 mm.

Rebranded Interface Offers Continued Injection Mold Cooling Data Efficiency

Burger & Brown Engineering’s rebranded Smartlink Tracer Interface can link to PC-based proprietary Data Logger software to receive voltage temperature and flow rate data for injection molders.

Photo Credit: Burger & Brown Engineering

Burger & Brown Engineering has rebranded its Smartlink Tracer Interface, formerly called Tracer Bluetooth Interface. The company says the name more accurately describes the most commonly used application of the product to “link” with PC-based proprietary Data Logger software to collect, transmit and store injection mold cooling data from Tracer Base units. This data is used to confirm injection molded part processing conditions commonly required by medical, military or aerospace manufacturing of critical components.

The Smartlink Tracer Interface supplies power and receives voltage temperature and flow rate data from up to eight Tracer Base flowmeters at one time. Data Logger software at the PC monitors up to 10 Smartlink Interface units simultaneously, providing real-time graphs, Turbulent Flow indication, out-of-limit alarm data and file management. A dry contact switch is available for connection to a peripheral or machine control to signal the alarm condition when data collection is active. Configuration files containing alarm settings can be saved and retrieved as needed for specific molds and machine combinations.

The Smartlink Tracer Interface also wirelessly transmits flow rate and temperature to display on a mobile device up to 20 m away. Compared to a PC, the mobile app displays data from up to 30 interface units at one time. Flow condition data log files can be created using the mobile app and saved onto a USB flash drive located on the interface unit.

According to the company, the Smartlink Tracer Interface is also more cost-effective if installed with economical non-display flowmeters in the cooling water line versus flowmeters that include individual displays. Scientific injection molders use temperature and flow rate data from Tracer Base units to confirm cooling water condition requirements, optimize cycle times and cooling water efficiency.

Stainless Steel Spiral Cores Issue Homogeneous Conformal Cooling

Hasco’s extended spiral core mold components in stainless steel guarantee efficient heat transfer and homogeneous core cooling for medical and cleanroom technologies.

Photo credit: Hasco America

Hasco America’s proven range of plastic, aluminum and brass spiral cores has now been extended with the steel grade 1.4305. Specifically, the stainless steel spiral cores Z9611 (single-threaded version) and Z9612 (double-threaded version) are now available, and round off the company’s recently launched range of stainless steel cooling units.

Excellent resistance and electrochemical corrosion ensure effective and homogeneous conformal cooling along the bore wall for medical and cleanroom technology. Further, high media resistance guarantees longer maintenance intervals, allowing for more efficient production of plastic parts.

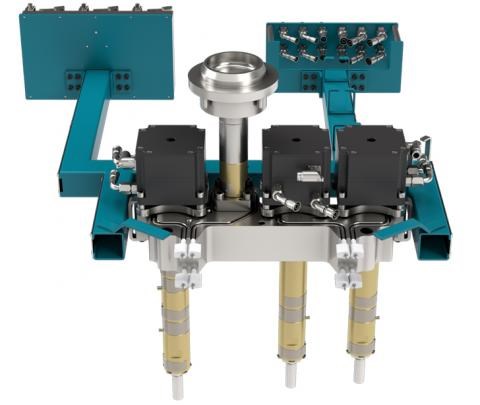

Servo Electric Valve Gate Design Minimizes Stack Heights, Simplifies Design, Improves Control

Mold-Masters’ second-generation SeVG+ motor system enhances control and precision over individual valve pins and offers users more interchangeability.

Photo Credit: Mold-Masters

Mold-Masters’ new, second-generation SeVG+ (Servo Electric Valve Gate) motor is a compact, direct drive design that has reduced stack height by 48% (at an installed height of 114 mm), simplifies mold design and offers superior process control for demanding applications.

With a footprint of 108 x 108 mm, the servo motor is interchangeable with Mold-Masters’ hydraulic actuator for added flexibility. The design itself has been made compatible with the company’s full range of valve pin diameters (2.0-9.5 mm) and incorporates integrated water-cooling channels for high-temperature applications. It is also well suited with molds utilizing magnetic clamps.

The SeVG+ motor has also simplified mold design in order to enhance performance/reliability and minimize cut-out/spare part requirements. This includes a motor with a direct drive design (meaning it does not utilize levers, gear boxes or other components to actuate the valve pin) for faster response rates and more precise movements; a single cable connection that can also swivel 180° to minimize cut-out requirements in the mold and speed up assembly times; and a valve pin that can be quickly and easily installed, or removed, without dismantling the motor from the hot runner system.

The servo-driven system provides absolute control and precision over individual valve pin opening and closing profiles, eliminating actuation variability and stabilizing the molding process for a better surface finish. User can fully adjust pin position (in increments of 0.01 mm), acceleration, velocity, stroke, timing and sequence to enhances molded part quality by controlling resin flow. Complex multi-step open/closing profiles are also made possible with up to 10 multi-step motion profiles (5 open/5 closing) that can be programmed, where each step can have individual setups. Programming these complex movements helps to eliminate visual imperfections like weld lines, hesitation marks and more.

Further, the SeVG+ maintains individual cavity shut-off capabilities. It is powered to handle large-part production and is suitable for processing demanding, rapidly freezing materials like PC where high closing forces are required for a proper gate seal. Mold-Masters’ servo motors have the additional benefit of having minimal maintenance requirements.

Mold-Masters’ SeVG+ system is compatible with all Mold-Masters hot runner systems which includes Fusion-Series G2 (drop-in system for medium to large parts), Dura+ (automotive lenses), Master-Series and Summit-Series (challenging resins). The product is available for all molding applications including large automotive and optical lenses requiring class “A” surface finishes.

Read Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)