MoldMaking Technology Noteworthy News, Aug. 04, 2020

The latest technology from Emuge, Meusburger US, and Walter USA

Micro End Mills Offer Longer Tooling Life

Available in solid carbide and CBN designs, Emuge Corp.’s new product is designed for high precision and difficult materials.

Emuge Corp. offers its new micro end mills product for a wide range of applications, such as die and mold, medical and more. The micro end mills feature a patented neck design with up to 10 times the diameter, enabling reach into deep contours. For optimal machining performance, the mills offer a high radial bending strength that withstands alternating stress on the cutting edge and relieved neck. The product additionally offers HSC finishing of 2D and 3D contours, and are offered in square, ball nose and torus end types. Featuring a short, stable cutting geometry, the end mills are available in solid carbide and CBN designs.

The solid carbide micro end mills are designed for high precision machining applications up to 55 HRC, and can machine small engravings, electrodes, components and cavities with varying depths. For heat and wear resistance, the end mills have a PVD-applied thin film ALCR coating which results in long tool life. Ball nose and torus solid carbide end mills provide high accuracy dimensional tolerances of ±5 µm. The solid carbide end mills are available with neck lengths of 2.2 by d1, 5 by d1 and 10 by d1 and a cutting diameter of 0.2 to 2 millimeters.

Emuge CBN micro end mills offer increased tool life for high precision, accurate machining applications up to 66 HRC. The end mills produce highly polished surface finishes without the need for rework. The CBN micro end mills are available with neck lengths of 1.5 by d1, 3 by d1 and 4.5 by d1, as well as a range of cutting diameters from 0.3 to 2 millimeters.

Piezoelectric Pressure Sensor Variants Improve Process Quality

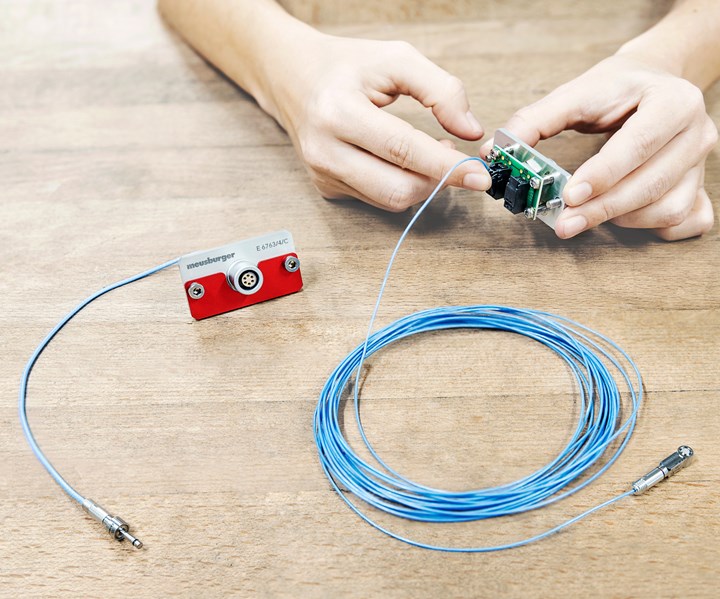

Meusburger presents two charge transfer versions, the single and coaxial cables with matching multi-channel connectors for cavity pressure sensors.

In addition to its existing range of cavity pressure sensors for plastic injection molding process monitoring, Meusburger now offers two charge transfer versions, the single wire E 6760 and the E 6757 mini coaxial cables, as well as matching multi-channel connectors for optimal process quality and increased part sustainability.

With a cable wire diameter of 1.2 millimeters, the single wire cable is ideal for molds with limited space. The wire can be routed flexibly with minimal bending radii, but may kink if not careful. Available in lengths of 2,000 and 5,000 millimeters, the single wire variant allows for shortening if required. Installation is effortless as a result of the insulation displacement connector on the multi-channel connector.

The E 6757 coaxial cable is characterized by optimal shielding against external signals due to its steel sheath, making it ideal for molds with a high number of electrical components such as hot runner components or monitoring equipment, or if the cable is routed outside of the mold. With a cable diameter of 1.9 millimeters, the coaxial wire is less flexible, but less prone to kinking, and is available in consecutive lengths from 200 to 1,000 millimeters. With Meusburger’s mini coaxial version, several sensor signals can be combined on one multi-channel connector.

The company’s offering of matching E 6763 multi-channel connectors, enables high process reliability during mold changes via a mold recognition chip integrated on the circuit board, and easy sensor data identification. Meusburger says the signals from 4 to 8 cavity pressure sensors can be combined with minimum cabling effort. Depending on the version, the multi-channel connectors also have insulation displacement contacts for the single wire cable (version S) and mini coax female connectors for the mini coaxial cable (version C).

FAQs on Leadtime Leader Questionnaire

Explanations of individual questions on Leadtime Leader Awards Competition submission form.

Profit (Surprised LLA has no profit measure)

Your shop's 2019 net income relative to gross sales

Formula = [(2019 net income/2017 gross sales) *100.] Include a minus sign if your number is negative.

Example: If your 2019 net income were negative $300, and your gross sales were $5000, you would enter -6

Return on Assets (ROA; Testing in Top Shops for the first time this year given potential to be a good measure of ‘success’)

Your shop's 2019 net income relative to total assets

Formula = [(2019 net income/2018 assets) *100.] Include a minus sign if your number is negative.

Example: If your 2018 net income were negative $300, and total assets were $10,000, you would enter -3

Work Mix

The proportion of your company’s work, in units, that falls into one of four types according to original or re-work.

Example: If your company delivered 120 units total, and…

- 70 units were original (i.e. not re-makes), you would enter 58% for ‘original.’

- 8 units were re-work of units your company already delivered, you would enter 7% for ‘re-work of your company’s original work.’

- 12 units were re-work of units another company delivered originally, you would enter 10% for ‘rework of another company’s original work.’

- 30 units were another type of work, you would enter 25% for ‘other type of work.’

- Your total would be 100% (58% + 7% + 10% + 25%)

First Pass Quality Rate

The percentage of product that passed inspection on first attempt; i.e. no re-work was required.

Example: if 8 of 10 of batches required no re-work after they were first produced, you would enter 80%

On Time Delivery Rate

The percentage of goods delivered to customers on or before the committed delivery date

Example: If 9 of 10 orders were delivered on time, you would enter 90%

Lead Time

The average number of weeks from receipt of order to delivery to customer

Quote to Close Time

The average number of days between providing a quote for a potential order and selling/booking it

Quote Conversion Rate

The number of dollars sold/booked as a percentage of dollars quoted

Example: If you quoted jobs totaling $250K and received orders for jobs totaling $225K, you would enter 90%

Sales Growth Rate

The 2019 revenue that is incremental to your 2018 revenue, as a percentage of your 2018 revenue

Formula = (2019 gross sales - 2018 gross sales)/2018 gross sales

Example: if your 2019 sales were $5000 and your 2018 sales were $4000, you would enter 25%

Age 25 & Under Representation

The number of shop floor employees under age 25 relative to your usual total number of shop floor employees

Example: If, on average, 5 shop floor employees were under age 25 and your usual shop floor staff totaled 30, you would enter 17%

Employee Retention

The percentage of employees in 2019 who were also employees in 2016

Example: If you had 20 employees in 2019 who were also employees in 2016, and on average a total of 60 employees in 2019, you would enter 33%

Apprentice to Journeyman Ratio

The number of apprentices relative to the number of journeyman on staff

Example: If, on average, you employed 2 apprentices and 8 journeymen, you would enter 25%

Regretted Turnover

The number of voluntary separations of satisfactory performers as a percentage of your total staff

Example: If 6 satisfactory performers left your company in 2019, and your usual total number of staff was 30, you would enter 20%

New Customer Rate

The number of 2019 customers who were new to your shop in 2019

Example: If you had 5 customers in 2017 who were not customers in 2018 or prior, and a total of 40 customers

in 2019, you would enter 12.5%

Organic Revenue Growth

The percentage of 2019 revenue that was incremental from customers you also supplied in 2018 or prior

Example: If your 2019 revenue was $500,000, and $60,000 came from customers you also supplied in 2018, and who contributed $50,000 revenue in 2018, you would enter 2%

Formula: (60K-50K)/500K = .02

Customer Referral Rate

The percentage of 2019 customers who were referred by other customers of your shop

Example: If you had 40 customers in 2019, and 2 of them were referred to your shop by other customers, you would enter 5%

Micro Drill Delivers High Precision and Productivity

Walter USA unveils the Supreme DB133 solid carbide micro drill with internal and external coolant capabilities.

Walter USA unveils the Supreme DB133 solid carbide micro drill with internal and external coolant capabilities. These drills are key to establishing precise, reliable working processes and achieving significantly longer tool life in steel, cast iron and nonferrous materials.

The use of Walter grades WJ30EL and WJ30ER specifically for micro drills, ensures that the drills exhibit superior wear resistance. In addition, the new cutting-edge geometry increases process reliability and optimized dimensions allow for maximum stability, even with the smallest drills. The uniform finish on the drill cutting edges and tight tolerances ensure that the surface finish of the drilled holes is excellent.

With the special flute geometry, the chips are evacuated effectively. This means that hole depths of up to 12 x Dc can be achieved. Oil or emulsion can both be used as a coolant with these drills. For deeper holes beyond 8 x Dc, Walter has also introduced a corresponding line of pilot micro drills, the DB131.

Drill Head Series Provide Consistent Performance

Sunnen Products Company offers a series of drill heads, inserts and pads that are directly interchangeable with Sandvik deep-hole drilling tools.

Sunnen Products Company offers a series of drill heads, inserts and pads that are directly interchangeable with Sandvik deep-hole drilling tools. The new line, Sunnen DirectDex, features BTA/STS (single tube system) and DTS/Ejector (double tube system) style deep-hole drilling tools designed to produce a low cost-per-bore with consistent performance. The series directly corresponds to the previously available line of Sandvik drill heads, inserts and guide pads, with additional product series set to be released soon.

CVD- and PVD-coated inserts are available in two grades, providing excellent wear resistance and toughness. The CVD-coated inserts are optimal for machining heat-resistant super alloys and also work well with ISO P, K, H and N materials. The PVD-coated inserts are specifically designed for ISO P, K, H and N materials, and also provide resistance against built-up edges.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)