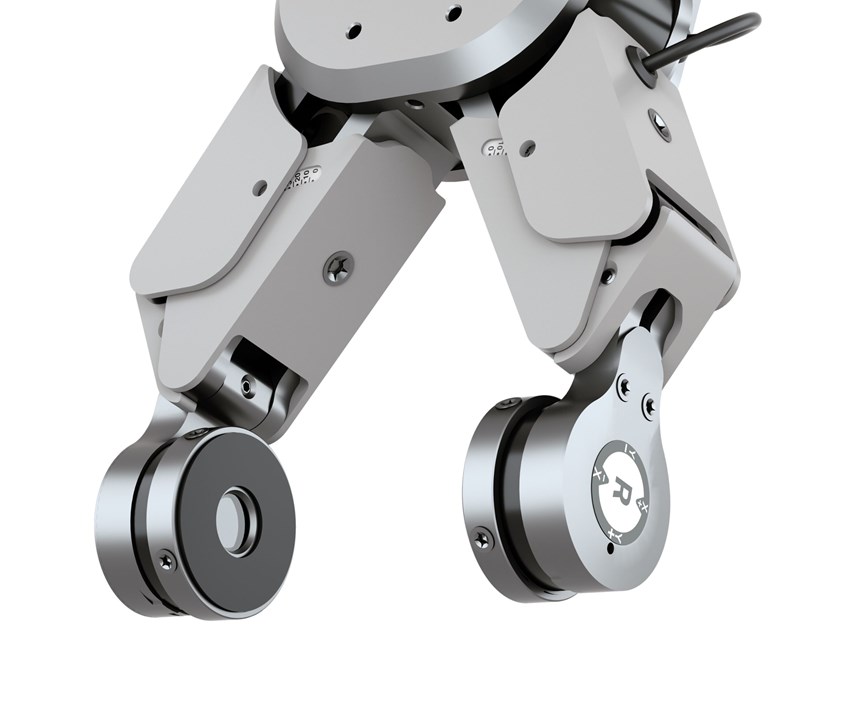

Grippers Designed for Efficient Task Automation

The new Gecko Gripper and RG2-FT update from OnRobot offer features for increased energy and cost savings, as well as efficient task automation.

Share

OnRobot offers its new Gecko Gripper and an update to its first edition RG2-FT intelligent gripper. The Gecko Gripper uses millions of micro-scaled fibrillar stalks that adhere to a surface using powerful van der Waals forces — the same way that geckos climb. The gripper enables robots to pick up flat, smooth objects and can affix to a wide range of surfaces, including fragile items. It also features the ability to operate in a vacuum, which enables it to pick up objects with holes. The Gecko Gripper interfaces with any robot while offering energy savings and a cost-efficient alternative to vacuum and electrostatic solutions.

The RG2-FT now features built-in force/torque sensing, supporting work in piece detection and centering. With built-in six-axis force/torque and proximity laser sensors at the fingertips, the RG2-FT can see and feel objects, ensuring faster deployment of collaborative applications and ultimately higher productivity. It also includes sensors with intelligent force feedback for adjusting applications for optimal design and positioning and can help in such tasks as assembly, insertion and quality inspection.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.