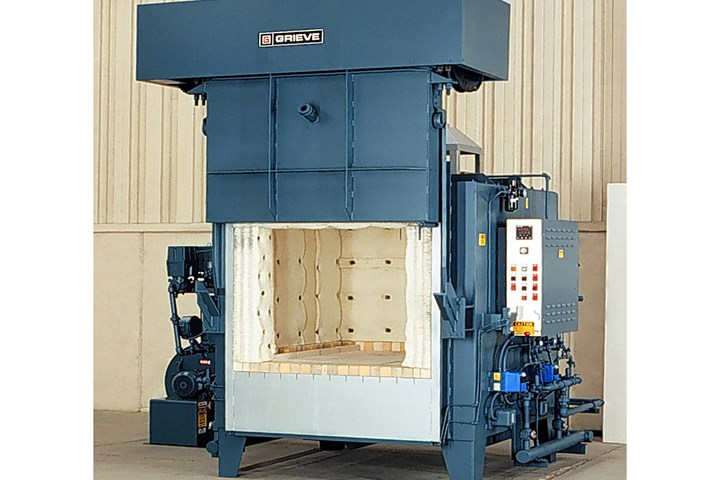

Gas-Heated Furnace Optimizes Mold Preheating

Grieve’s furnace heats up to 2000°F(~1093.3°C) and 7-inch-thick floor and wall installation enable consistent heating.

Photo Credit: Grieve Corporation

Grieve Corp. introduces No. 862, a gas-heated 2000°F(~1093.3°C) furnace currently used for preheating molds. The furnace has 750,000 British Thermal Units per hour (BTUh) installed in four modulating natural gas burners with a floor-mounted combustion air blower. Workspace dimensions are 36 inches wide x 48 inches deep x 36 inches high.

The unit retains 7-inch-thick insulated walls, comprising 5 inches of 2300°F ceramic fiber and 2 inches of block insulation. The 7-inch-floor insulation contains 4 ½ inches of 2300°F firebrick and 2-½ inches of block insulation.

Controls onboard No. 862 include an automatic door switch to drive burners to low fire when the door is opened and an air-operated vertical lift door. All safety equipment required by the IRI, FM and the National Fire Protection Association Standard 86 for gas-heated furnaces is also included.

Related Content

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

.jpg;maxWidth=300;quality=90)