Expertise in Mold Repair and Revisions Makes Quality Mold Inc. A Valuable, Full-Service Resource

Quality Mold Inc. does everything in house including mold repair and refurbishment. Customers also benefit by a mold warranty, financing and guidance.

You have a full-service mold shop. What exactly does that entail?

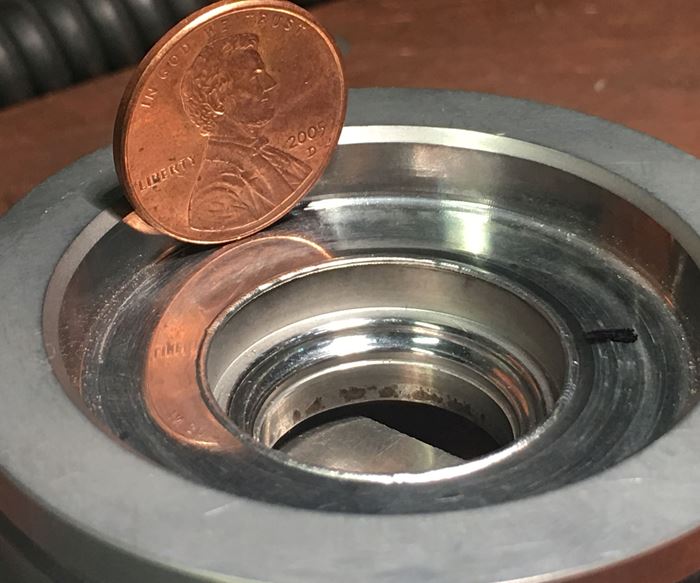

Steve Burke, plant manager: Quality Mold started out as a side business in Mike Hatfield’s garage, providing welding and other repair services. He is a journeyman moldmaker and could also build molds, and as customers’ requests grew, so did the company. He bought a Bridgeport and a grinder, and the company grew from there. Today, about 70 percent of our business is mold repair and revision work. We can do just about everything in house except heat treating and specialty coatings. We also build new molds and in fact we have three being built now. We have six CNC machining centers, including Mitsubishi TV-500 and a TV-700 high-speed milling machines, Matsuura MC-600VF and MC-1000V milling machines; we have four EDM machines (wire and sinker) including two Mitsubishi EA12VM Advance sinker EDMs with a Mitsubishi MELFA RV-12SL robot, and we have several Mitsui surface grinders with Opti-dressers. We have our own welding department where we can TIG weld, micro TIG weld and, in the last four years, laser weld using our LaserStar 7700-3 Series Open Workspace Welding Workstation.

Quality mold inc.

How did Quality Mold come to provide mostly mold repair and revision work?

Burke: The company’s roots are in mold building, but we came to do more repair and revision work back when everything started going to China. We had to change our way of thinking, so would tell these customers that when their molds come in from overseas, give them to us. At that time most molds would come in with issues and we would work on them and get them to run correctly and get the dimensions in tolerance. It became our little niche business because a lot of shops would not touch a Chinese-built mold. We would say send them to us; we'll work on them. We became familiar with Chinese-built tooling. A lot of it was all handwork and they would cut things close and then go in with the disk grinder and grind away until they got it to where they wanted it and leave it at that. None of the surfaces would be correct to a solid model, so we would reverse engineer these molds and make sure they met specifications.

We also do a lot of mold refurbishments. Some of our bigger customers had older tooling built in the U.S.A. in the 1980s and 1990s, so they will send them to us, and we will put in new leader pins, bushings, locks, etc., and go over the molds and correct any issues like flash and make them some spare tooling as well. Their part designs haven't changed any, so they have molds with several million shots on them that they would like to keep in production. We do whatever is needed to keep those molds running.

Besides molds, we use our two Fanuc Alpha-1iA’s and our Fanuc Alpha C400iB wire EDM machines to do a lot of work for several aerospace customers.

Speaking of tolerances and specifications, Quality Mold offers a mold warranty. How does that work?

Burke: For any mold we build, if it has any issues like the workmanship, the function or the tool design, we will take care of it. The warranty covers cavities, cores, parting-line surfaces, and ejection. For example, if the runner's not dropping like it should be, there's an issue. Maybe it's a three-plate mold and the puller pins aren't holding the runner; we'll get the mold back and we will do what it takes to fix it. We will increase that undercut and make any kind of design adjustments free of charge. When we're done with the mold, they should have a full functioning mold they can put into the press and run.

It’s about relationship building. If I am in the middle of a mold repair I quoted, on any mold, and I find something else that isn’t right, I'll alert the customer and either go and take care of it at no charge, depending on what it is, or we will work with the customer to get it resolved. A lot of our customers have been with me for over 15 years. I'm knowledgeable about what they need to get done and I'm familiar with their molds. We are a busy shop, but if a loyal customer needs something done quickly, I’ll do whatever it takes to get that job done for them asap.

We also have an inspection room with a coordinate measuring machine (CMM) and optical comparator, both from L.S. Starrett Co., plus a Vision Engineering Macro Dynascope with Quadra-Chek vision system. We use these instruments and others to thoroughly inspect our work in process and before it is shipped. For example, if we are machining electrodes on the Roku–Roku HC-548EX High Graphite Milling Machine, the operator will make the first one and take it to the lab to inspect it. Then he takes it to the lead man on that job and the lead man will inspect it, giving him the go ahead to make more if it is good or directing the operator to cut a new one. This same procedure is followed for every mold component, 2D or 3D, although much of the 2D work can be inspected using calipers, micrometers, height gages and so on. We do a lot of hard milling, so when we get a job back from heat treating, we begin hard milling after grinding everything square & parallel. We’ll program it, cut it close to tolerance and then use the CMM to see what we have, particularly with shut offs, then we adjust to do the final cuts. We always insist on two people doing these inspections to ensure nothing is missed.

Finally, we have a 3D Systems Konica Cubepro Trio 3D Printer, which we purchased about three years ago to provide prototype parts for customers who wish to determine the fit and function of parts they design before we build the mold.

Quality Mold offers financing. What is that all about?

Burke: That's something that our office manager set up. The financing is not through us but it's through a company that will provide financing for inventors that have new products, but they don't have a lot of money and they're not aware of what it takes to have a mold built. They may have an idea for a little part, but they have no idea that a M.U.D unit could cost around $10,000. It is not unusual for me to get inquiries along these lines once a month, so we have this service for them. There is a link on our website where they can apply to get the funding that they need to build the mold. I also try to educate them about molds and molding. Most people think we work with plastic; they have no clue what a mold is. Sometimes I have to tell these inventors that they are jumping ahead too fast and that they need to meet with a part designer to ensure their product is moldable. If it is then I tell them to get a 3D model or at least a 2D sketch of the part and then we can provide a more realistic quote for the mold. I also advise them about locating an injection molding company and probably someone in marketing so they can properly market their product. There are a couple local companies that I'll refer them to for the part design and the marketing aspect of it. But nine times out of ten they have no clue what a mold cost, and when I give them a ballpark estimate their eyes get big. If they say they might have to go to China because of the pricing, I warn them to be careful where they go because some places will build one mold for them and a second mold for themselves to run and sell the product there.

Related Content

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreHow to Maintain Heaters, Thermocouples, Valve Gates and Controls

An examination of real-world problems and solutions involving hot runner system maintenance.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)