e-Spindle Enables Full Participation in Smart Manufacturing

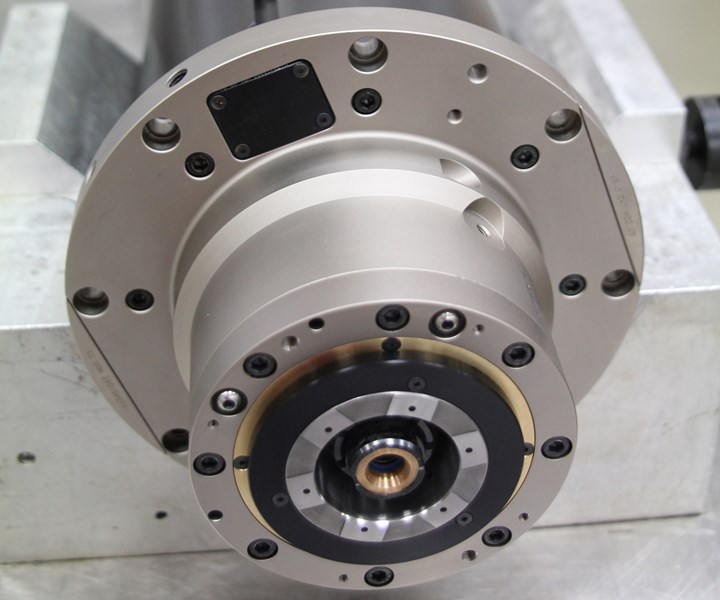

Absolute Machine Tools partner PCI SCEMM (a Tongtai company) introduces the e-Spindle, an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality.

Absolute Machine Tools partner PCI SCEMM (a Tongtai company) introduces the e-Spindle, an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality. The e-Spindle technology enables customers to fully participate in smart manufacturing.

The e-Spindle showcases smart machining technology with real-time monitoring of cutting process variables including force, vibration and coolant pressure. An adaptive drilling application illustrates the benefits of ongoing vibration control, and a honing toolholder operation features integrated measurement of workpiece diameter to permit continual control of abrasive honing tooling.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

.jpg;maxWidth=970;quality=90)