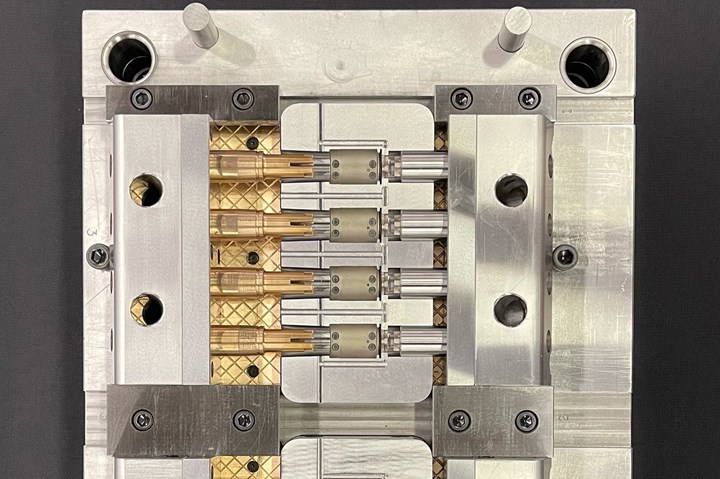

Cross-Functional Mold Design and Engineering Team Drives Complex Component Manufacture

Michiana Global Mold specializes in Class A finish, highly complex and multi-material parts and offers customers expertise in building complex injection molds with more moving features.

Photo Credit: Michiana Global Mold.

Since 1964, Michiana Global Mold (MGM) says it has been a world-class designer and builder of plastic and rubber injection molds for the automotive, medical, industrial and consumer products markets. The company specializes in Class A finish, highly complex and multi-material parts. Its cross-functional design and engineering team works in collaboration with all journeyman moldmaker craftsmanship to build single to high-cavitation molds for tight-tolerance parts including hot/cold runner, collapsible core, insert, overmold, shuttle, stack, unscrewing, two-shot and rotational. MGM’s Chinese partnership also enables the company to bring in both fully finished, and semi-finished molds to maximize cost savings; molds are then fully managed, inspected and serviced by its U.S. team. Overall, the company reports that it employs the best in technology to offer mold trials, sampling, validation, production part approval process (PPAP) and prototype runs as single-sourcing solution to a customer’s tooling needs.

MGM notes that it has vast experience and expertise in building complex injection molds with more moving features, tighter tolerances, multiple and buried cams, hydraulics, split parting lines and delayed/multiple ejections. Its team are said to be experts in addressing complicated injection options, cooling issues, water lines and gate placement. MGM contends that it offers advantage to any plastics manufacturer challenged with participating in a direct global-supply chain model.

.jpg;maxWidth=300;quality=90)