Automation Is for Small Manufacturers

Although there is constant talk about Industry 4.0 and automation, many smaller manufacturers I speak with are challenged with understanding and implementing these concepts. I came across this white paper that breaks down how to use available networking and automation technology to compete like the big guys.

Thomas Mathew is a software product manager at ANCA CNC Machines who believes that automation technology has leveled the manufacturing playing field, saying that “Now smaller firms can be nimble, niche, and with new efficiencies compete against the big guys.”

Here are some technology and marketing insights from Mathew with a focus on tool manufacturing for grinding as an example all small shops can learn from:

New technology means that smaller businesses have access to a huge amount of capability that may have been too large an investment in the past to consider. Automation also reduces the cost of manufacturing meaning companies don’t need a huge turn over to be viable and competitive. The networking of older machines can be achieved at relatively low cost, and the production benefits can be huge.

A report by Deloitte shows high performing manufacturers outperform their competition not because they’re bigger, but because they leverage brand, reputation, new markets and customers, and advancing technology. To use available networking and automation technology focus on quality, break down the experience barriers, increase production, harness automation for your own production boom and shout from the top of the internet.

Let’s consider tool manufacturing for grinding. It’s quality that counts, and smaller companies are now able to run production which automatically measures and corrects tool grinding precision to ensure that accuracy is no less than the very best. If you have the right machine and the right software, you can grind a wide variety of tools without having specialist knowledge about them, or previous experience with that tool type.

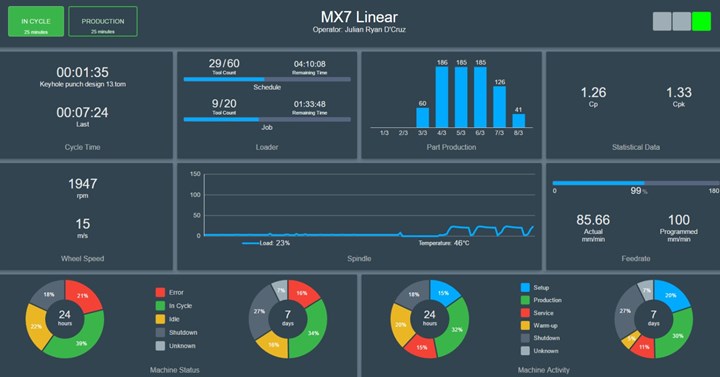

Even though you may be smaller, automation can really boost your production output. Long gone are the (long) days where machines must be manned all the time, and all the weekend. By networking and automating your existing systems you can run 24 hours a day, 7 days a week in ‘lights out’ mode.

Not only can production be automated but your whole process can benefit from machine networking. Integrate your ordering, invoicing and dispatch to reduce administration and allow flexible work. You’ll gather insights into your whole process from end to end, making it faster for you to adapt and change to different market pressures. With a finger on the pulse of your production, you can optimize it and watch it take off.

Related Content

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreMaintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)