3D-Printed Mold and Part Polishing Service Advances AM Geometry and Material Capabilities

Ultra Polishing extends its services for polishing 3D-printed plastic molds and parts and printed metals, for companies creating products with complex dimensions and using nontraditional materials.

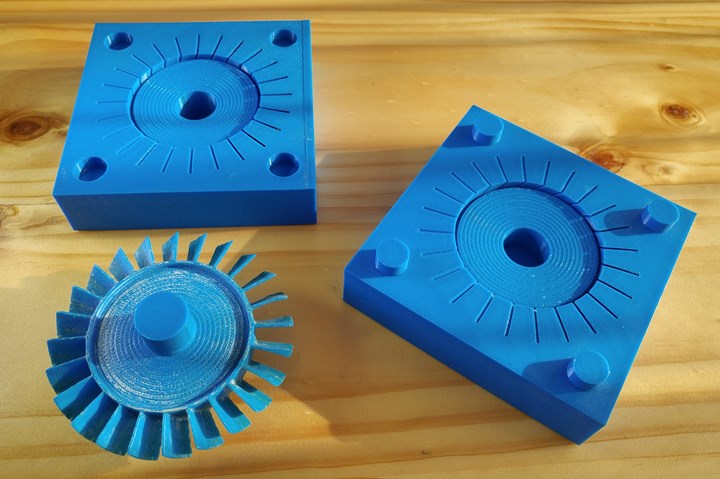

Photo Credit: Ultra Polishing

Ultra Polishing has expanded its 34-year experience in mold and machined-parts polishing into offering services for polishing 3D-printed plastic molds and parts and printed metals. By adding this capability to its repertoire, the company hopes to provide a readily available service to additive manufacturing (AM) companies that are creating new products via complex dimensions and unconventional materials that require polishing for the mold or part to properly function.

Ultra Polishing notes that moldmakers, molders and OEM’s have integrated its polishing capabilities into their AM R&D and prototyping processes. As a result, Ultra Polishing has invested resources researching and developing new in-house processes utilizing nontraditional materials for polishing printed tools, both plastic and metal.

Related Content

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.