VIDEO: 2020 Leadtime Leader Award Winner: Precise Tooling Solutions Inc. — The Power of People and a Plan

The proof is in this winning shop’s three-pillared value proposition and three-phase growth plan that promotes empowers people while promoting quality product and profit.

“It’s all about the people,” Don Dumoulin, CEO/Owner of Precise Tooling Solutions says. And by people, he means the employees and the customers.

Vision Statement: We will build upon a talented team, cutting-edge technology, and superior efficiencies to deliver only the highest quality products to delight our customers while continually increasing profitability.

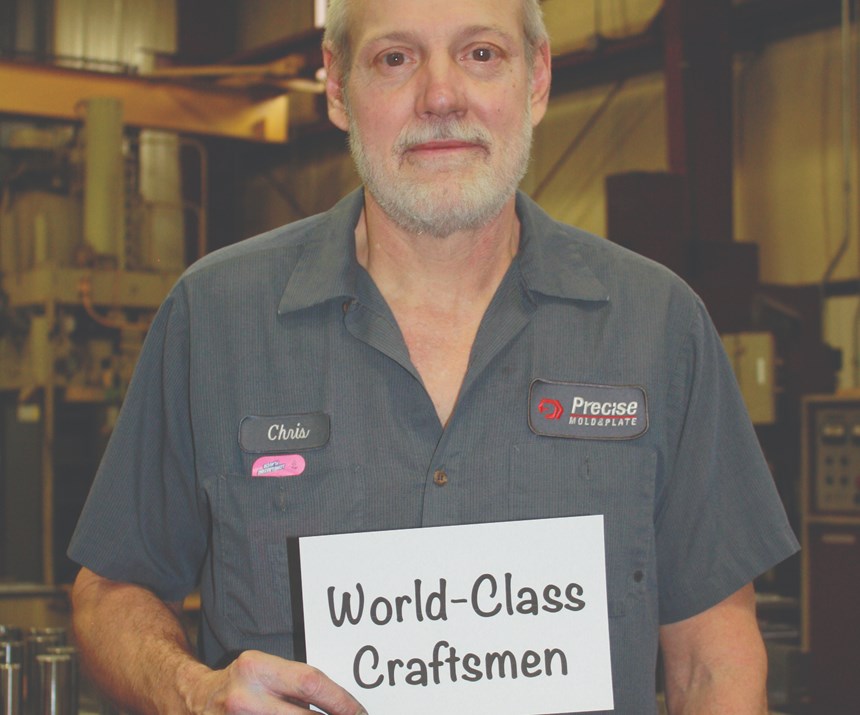

This vision statement focuses on people, customers and making money. “We have to do everything we can with our people, customers and technology to make sure that we have a successful bottom line,” Dumoulin says. That is why he describes the company’s value proposition as having three pillars: on-time delivery, world-class craftsmanship and a fair price.

“You're always going to get on-time delivery with us. In fact, last year our on-time delivery was north of 98 percent. And, you are always going to get world-class craftsmanship and a fair price,” Dumoulin says.

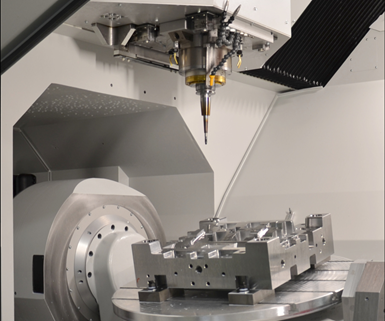

The major benefit of five-axis machining is the ability to mill highly complex shapes in a single setup. This game-changing technology means Precise Tooling’s customers receive unprecedented precision and shorter lead times.

The key to living up to these expectations is knowing who you are. Dumoulin emphasizes that Precise Tooling is not a tool shop. Instead, it’s a specialty manufacturer with four business units under one roof: new injection mold building focused on tight-tolerance optical lighting and thermoset tools; mold repair and productivity improvements on tools currently in production; managing large and complex CNC machining projects; and building custom ergonomic workbenches lift bases for

High-speed five-axis mills like this Roeders are used to achieve the dimensional accuracy which is key to thermoset molding. The Precise team understands the complex geometries and unique construction requirements, enabling them to deliver flash-free thermoset tools that go straight into production.

assembly and material handling applications. This diversified business model is pretty unusual compared to most tool shops.

“Building new plastic injection molds is the largest of these business units, but the tool repair service, CNC and ergonomic table businesses give us four strong and profitable legs to stand on, which helps us weather any storm,” Dumoulin says.

However, when push comes to shove, moldmaking is his priority. The company has dedicated teams for each of the business units, and cross-training allows leadership to pull resources for tooling projects as needed. “We’re good at utilizing our resources the best we can, and we know how to build a really good tool. I like to tell prospective customers that we don't know how to make a cheap mold,” Dumoulin says.

Dumoulin talks about how tool complexity in the injection molding industry ranges from plastic spoons and forks to complex thermoset lighting and medical devices. It is a broad spectrum, and they provide engineering changes and repair services on the entire range. That said, a significant portion of the new tools built are destined for automotive lighting companies, especially those launching LED products. “We have a specialty in automotive lighting, as we build and repair tooling for 75 percent of the companies in America that provide the vast majority of the lighting parts in the automotive industry,” Dumoulin says.

The company’s reputation as a top-flight builder of thermoset molds is well-deserved. They understand the complex geometries and unique construction requirements and use the latest five-axis mills to achieve the dimensional accuracy that is key to thermoset molding. This approach allows them to deliver flash-free thermoset tools that go straight into production. In fact, one of their Tier 1 customers recently told them: “hands down, you guys build the best Thermoset lighting tools we see.”

For 2019, Precise Tooling reported 5% sales growth, a first pass quality rate of 94.6%, average on-time delivery rate of 97.2% and average lead times that range from one to 12 weeks depending on the type of project.

Knowing Your Roots and Adding Value

Known initially as Precise Mold, the company has been designing, manufacturing and repairing injection molds for more than 33 years. The company started modestly with a handful of employees who wanted to apply their mold industry knowledge to the process of making better molds. Slowly but consistently, the company grew in both size and reputation by building high-quality tools and repairing production molds quickly and at a competitive price.

Dumoulin, a seasoned executive from the consumer goods and the medical device industries, purchased the business 2013 after a short-lived retirement. “I was looking for an opportunity where I did not need to manage the day-to-day tasks. My skill set is corporate finance, leadership and strategy. I wanted to invest in something that needed those skills. I wanted a business where I would be value-added,” Dumoulin says.

Precise Mold was perfect. The company had plenty of experienced craftsmen doing what needed to be done to grow the business. Still, they didn't have a growth platform, a strategic plan or leaders with the right responsibilities. Dumoulin’s skill set was a perfect match. “It’s really about the people. I'm additive to that,” Dumoulin says.

In the seven years that followed, he used a strategic approach to make significant investments, including adding an ERP system, state-of-the-art machining technology and new software enabling Precise Tooling to meet customer expectations for high quality at a fair price. He also acquired the ergonomic equipment business, which prompted a decision to rebrand the company in 2017 as Precise Tooling Solutions.

Leading People and Creating Culture

What makes Precise Tooling unique is its 36 employees from the front office to the shop floor, and that is what motivates Dumoulin each day.

“I believe in people, and when you fully trust people, it empowers them. I truly don’t run the shop. I didn't come from a tooling background. So, I give people the authority and the ability to make the right decisions. You have to build a team and give them power. Give them the runway,” Dumoulin says.

I believe in people, and when you fully trust people, it empowers them. You have to build a team and give them power. Give them the runway.

Part of building trust is transparency. Dumoulin has always been a big believer in each employee knowing the impact he or she has on the work done in their group and across the company. This level of understanding requires metrics such as revenue, profitability, costs, projects that make money, and projects that lose money.

“Unless people truly understand how they impact the company, they are rudderless,” Dumoulin says.

So, he provides full transparency to the entire organization. Dumoulin holds town hall meetings throughout the year with all the craftsmen and provides information about the company's key financial metrics. He gives the four general managers individual P&L statements, so they each know precisely the amount of money they're making off every project and the performance of the business unit for which they are responsible. And, the eight-person leadership team meets every month to go through detailed financial reports.

Dumoulin strives to do the right thing by his people and take care of not only the individuals who walk through the door every day but the families, too. He believes that a happy employee is going to do a better job, make a better tool, make a better table, make a better CNC project, and that is what matters to the customer. “My job is to make sure that we're financially stable, that we're making the right capital investments and that our customers are delighted in the work they get from us,” he says.

Achieving Operational Excellence

Speaking of capital investments, when Dumoulin came into the picture, the company had a long relationship with a couple of automotive lighting companies. However, Precise Tooling was falling behind the technology curve relative to the evolving needs of those customers, so they were about to lose the business. “That's when we upped our technology game to move back to the forefront of the moldmaking industry,” Dumoulin says. He implemented a three-phase plan.

Precise has a separate business unit that provides Tool Productivity services such as engineering changes, preventive maintenance, productivity enhancements and emergency repairs on tools, including those built in China. Shown above is a repair project for a mold used to make biodegradable spoons.

During Phase 1 (2013-2015), the company transitioned to a more sustainable business model. They installed an ERP system, created a digital environment and layered on an ISO certification so that they had a quality language to talk about across the organization.

“These were gut-wrenching changes for our craftsmen who were used to writing down their hours on a piece of paper and handing it to the administrator. And working whatever hours they wanted to on a project without a goal in mind—in terms of how much money we were going to make on that tool,” Dumoulin says.

Phase 2 (2015-2017) was all about upgrading equipment. “We doubled down and invested in the latest and greatest technology,” Dumoulin says. Their purchases included their workhorse, a five-axis FERMAT machine that efficiently manages large projects with complex geometries. They also took delivery of one of the few five-axis lens-quality Roeders mills in the Midwest.

The team focused on software analysis in Phase 3 (2017-present). They looked at the software the shop was running, programming and executing, and how they managed IT and cybersecurity. “We are currently migrating to a unified software approach. We are shooting for an integrated software platform that ties everything together from design through final product fabrication,” Dumoulin says.

Collectively, Precise Tooling invested nearly $4 million on new five-axis and EDM technology during Phases 2 and 3. This level of investment brought in new people who learned new skills, which has made the company a stronger, more cost-competitive manufacturer, according to Dumoulin. “Our largest customer told us recently they previously had 12 tooling vendors; they're now down to five, and we're one of them. That's a good spot to be in.”

Precise Tooling builds a broad spectrum of tooling, but the majority of its new tools will be for automotive lighting companies, especially those launching LED products.

The result of this multi-year investment plan was profound. Precise Tooling changed the way it produces molds. “The old way of building molds where a lead man manages the whole process, including building the mold, doesn't work anymore. Technology advancements—including five-axis machining that produces inserts at net shape, reducing the need for polishing and EDM, and decreasing blue-in time from 30 hours to two hours—have changed the lead man’s role to that of an orchestra conductor instead of the guy doing all the work,” Dumoulin says.

Precise Tooling has pivoted its operation to this new manufacturing method, which is keeping workers longer with less strenuous work, while taking significant time out of the production process and reducing manufacturing costs. Their next round of technology investment will likely include EDM automation.

Driving Savings with Advanced Technology

Precise Tooling’s lead times prove the team’s dedication to customer service and commitment to advanced technology and processes. Director of Manufacturing Josh Jeffries has a handle on the team and the arsenal of new technology, which has taken this specialty manufacturer to the next level.

A multi-year investment commitment to the five-axis technology like this large Fermat mill and the latest design software has dramatically reduced setup and machining times, while improving the quality and consistency of CNC projects.

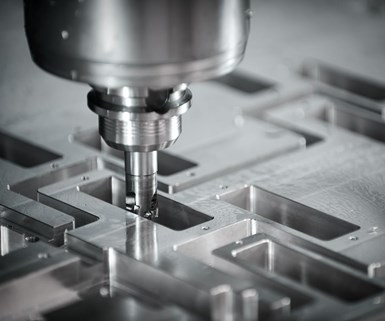

For example, upgrading the core operating software that runs the majority of the CNC machines with Autodesk PowerMill and PowerShape has dramatically improved cutting cycles and shortened lead times for both new tooling and mold productivity projects over the past year.

“The new software enabled us to better understand new ways to optimize machining precision and surface quality on our most complex tooling projects,” Jeffries says.

In 2019, Precise Tooling expanded its software partnership with Autodesk with the implementation of Fusion 360, which unified design with manufacturing. “This meant our craftsmen could go from design to machining faster,” Jeffries says. Autodesk was so impressed, they sent a videographer to capture how Precise Tooling operationalized the software. That footage is now featured within Autodesk’s employee training program and their website marketing content.

Precise Tooling’s customers benefit from the company’s massive arsenal of CNC equipment, including wire and sinker EDMs, large capacity horizontal and vertical mills, and Blanchard grinding machinery.

Advanced machining technology always shortens lead times and improves quality, as proven by Precise Tooling’s newest machine, a Roeders RXU five-Axis 1001 mill. Along with new fixturing, they use this high-speed machine has given the company the best bang for its buck. They went from multiple setups for parts that have milling on each side to one setup, according to Jeffries. But it’s the mold surface finish that is of the utmost importance when it comes to their lighting molds. “A test part on the Roeders shaved 80 hours off our polishing time,” Jeffries says.

Advanced five-axis machining capabilities allows Precise Tooling to pick up optical insert work and work on projects in the LED lighting space they would not have been able to do before. “Light pipe technology advances so fast, forcing us to keep up with technology. As tool complexity grows, we have to evolve with it,” Jefferies says. “We’ve also eliminated about 25-30 percent of our EDM work for new tooling.”

Jefferies had to mention the team’s other workhorse, the Johnford 3100SH vertical bridge mill. This machine is used in all four of Precise Tooling’s business units because of its wide work area and ability to both rough and accurately finish a mold. “It has unmatched diversity,” Jefferies says.

The next step is software to automate the programming for the CNC and EDM areas, which will help Precise Tooling optimize machine runtimes.

“With our new machine technologies, we've chipped away at our blue-in times as much as we have our polishing times. Blue-in time would run 80 to 100 hours, and now we see 10 to 20-hour blue-in times, depending on mold complexity,” Jefferies says. The Millutensil blue-in spotting press has proved very valuable to the repair side of the business.

When it comes to inspection, Precise Tooling tailored its technology and offerings to customer needs. “We use a FaroArm with surface plates to inspect parts, which minimizes cost for our customers and ensures that their parts are checked according to their requirements. For anything more than that, we subcontract it out. The versatility of the FaroArm is key. We can pull it from its stand and then inspect on the machine,” Jefferies says.

Enhancing Production Molds

Precise Tooling’s Mold Productivity Unit services molds of all sizes and complexities, from small cable lock parts to large truck headlight housings. This unit represents about 30% of its overall revenue. A dedicated team of productivity specialists proactively reach out to customers about scheduled shutdowns, and they work around the customer’s schedule to evaluate mold surfaces, make engineering changes or conduct preventive maintenance.

The decision to update the company’s name in 2017 was deliberate. New tooling services had been introduced in recent years, and long-tenured customers had always been quick to call Precise when problems arose. So, it seemed entirely appropriate to rebrand themselves as Precise Tooling Solutions.

Nowhere is that more appropriate than the company’s Tool Productivity business unit. It currently represents about 30% of top-line revenue and continues to grow at a healthy clip. Other tool shops often label this area ‘Repair & Maintenance.’ Precise Tooling takes a more holistic view, as the craftsmen assigned to this business unit provide a wide range of services such as engineering changes, preventive maintenance, productivity enhancements and emergency repairs. And not just on the tools they build.

Brian Rose is the program manager for tool productivity. He’s responsible for issuing Tool Productivity quotes and serves as the quarterback on most non-routine projects. “I like to get all hands involved at the very beginning of a project,” Rose says. “That way, everyone knows up front what the customer expects, what the team needs to accomplish, and each craftsman’s specific role in that process.”

CNC machining of plates has grown steadily over the past 10 years. A team of long-tenured craftsmen have seen virtually every kind of project imaginable and love to manage complex CNC projects other shops won’t tackle.

It is hard to find an engineering change or productivity improvement someone on this team hasn’t seen before. Experience matters, and it’s a challenge to maintain the collective experience as the more seasoned craftsmen transition to retirement or part-time roles. Rose explains it this way, “We’re picky when we screen potential hires. We want them to have some level of hands-on experience, but we also want them to be open to how we train new craftsmen. That’s why we pair new hires with a more experienced person who can teach critical thinking and problem-solving skills and do so while managing a live customer project.”

Rose likens his team’s approach to the current coronavirus environment. “Above all, our group needs to be adaptable. Things can change quickly, especially with lead times, so we have to stay on our toes."

Streamlining Scheduling and Working in the Cloud

Five years ago, Precise Tooling implemented an on-premise ERP system that proved to be transformative. Shoptech’s E2 took Precise Tooling from a paper-intensive environment with spreadsheets and sticky notes to an all-encompassing project management software that provides what-if modeling for planning productivity.

Then in 2019, Dumoulin decided to transition to a cloud-based version of E2, which eliminated the need for servers and hardware in the facility. It also meant that the vendor was now responsible for security, maintenance, upgrades and issue resolution.

My job is to make sure that we’re financially stable, that we're making the right capital investments and that our customers are delighted in the work they get from us.

Cloud-based deployment provides Precise Tooling flexibility. “It allows us to add features at any time without having to purchase new software. The user experience is intuitive, too. Users access the E2 via secure internet connection in our facility, from a customer’s facility or anywhere else. Also, users have complete functionality from computers and mobile devices,” Dumoulin says.

Then there is the enhanced process for exchanging large data files with tooling customers. Mold design files are typically too large to send via regular email. Plus, email transmittal poses an additional risk of data loss. In 2019, Precise Tooling transitioned to OneDrive for transferring large data files. OneDrive is fully integrated with other Microsoft’s cloud-based applications that Precise Tooling and many of its customers use.

“E2 helps drive the shop. It is the backbone of planning jobs from order entry,” Jefferies says. Before E2, the team would jump around a lot when machine scheduling and trying to mesh departments, which destroyed machine efficiency and communication across the shop. With E2, all the employees can see a problem before it gets to them. Plus, E2 helps forecast delivery times and provides a plan to stay on time.

“Six years ago, I spent all day, every day just manipulating the schedule for the shop and making sure things were moving correctly. Today with E2, no one needs to manipulate schedules. The process of writing up and entering an order takes about 30 minutes, and then it’s automatically scheduled. Now we just monitor a job,” Jefferies says.

Precise Tooling’s data tracking is also managed within E2. E2 records quality mistakes and offers a searchable database of mistakes, which helps with the shop’s monthly quality review meetings. Jefferies notes they looked at investing in machine monitoring last year, but because he was able to use E2 to machine monitor and yield significant gains, he decided to forego investment in machine monitoring software.

Migrating to cloud-based ERP offers significant IT security advantages, too. Shoptech partners with Google Cloud, a pioneer in server security who operates three redundant data centers in the U.S., mitigating concerns about server downtime.

Listening to the Customer

“Enhancing customer productivity is why we exist, and exceeding customer expectations is at the core of our culture,” Dumoulin says. So, how do they know they are doing a good job?

That’s the job of John Rowe, who does double duty as the company’s marketing director and ErgoSmart program manager. Since 2013, Precise Tooling issues a survey for all projects for every client. They send survey invitations to multiple contacts for every project invoiced during each survey period. They use Survey Monkey to administer the survey. It has 18 simple questions and takes about two minutes to complete from either a desktop computer or a mobile device. Four of the 20 questions have been included in every survey and form the core of the survey. Knowing that many survey respondents are long-time customers, Rowe believes that responses to these four questions provide valuable longitudinal data about current and emerging trends.

This flat-butt welder horn illustrates why Precise Tooling’s craftsmen are recognized across the Midwest for managing complex projects from concept through delivery.

For example, respondents are asked to identify the top three selection criteria when looking for new suppliers. “It's fascinating; if you look at the results over the last six years, lead time was not in the top three for the first couple of years. Fast forward to today, and lead time has been the number one ranked criterion in the last three surveys,” Rowe says. “Another key question asks if Precise Tooling is easy to do business with. Everybody's busy these days, and we think that if we can be easier to work with, we're going to win more than our fair share of new business.”

Precise Tooling also provides a year-over-year comparison of 15 dimensions of customer satisfaction. After each survey, they share results with their customers and post a summary on their website that is available to everyone. “Our survey results confirm that customers are willing to pay for world-class craftsmanship, so long as it’s a fair and competitive price,” Dumoulin says.

Enhancing customer productivity is why we exist, and exceeding customer expectations is at the core of our culture.

Lastly, they publish on-time delivery performance metrics each month on their website, highlighting their commitment to transparency, which applies to marketing as well as to culture.

Managing the Brand

What good is all of this work if no one knows about it? Rowe set out to redefine customer service and marketing for a mold manufacturer because “although we invest in manufacturing technology, software and digital marketing, at the end of the day, our customers view Precise Tooling as a high-touch service provider.”

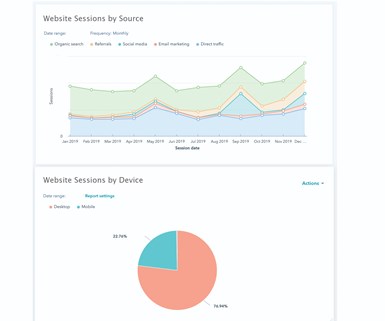

To set things in motion, Precise Tooling licensed HubSpot software in 2015. HubSpot is a cloud-based software suite for the entire front office of an organization—including sales and marketing, web hosting, search engine optimization, social media, blogs, outbound e-mail marketing, public relations, as well as press management and proactive customer communication. HubSpot also houses Precise’s customer contact data, company information and detailed quote data within a relational database is literally the hub to all Precise Tooling’s digital marketing programs. What makes this incredibly valuable is its sophisticated data analytics that provides real-time, end-to-end management of all sales, marketing and customer service processes.

HubSpot’s cloud-based software integrates all of the company’s ‘front office’ sales and marketing functions within a single platform. Shown here are real-time analytics for a recent email campaign, showing email open rates, the number of people who clicked or downloaded information, and how much time was spent reading versus glancing at the email.

“E2 is our manufacturing software. Think of HubSpot as the integrated software where everything we perform during the sales and marketing processes is digitized and archived, then handed off to E2 when the PO arrives. For example, a program manager creates a quote and issues it to a customer contact directly from the contact database in HubSpot. And he’s able to see all quotes we previously issued to each location and each contact at that customer. So, at a macro level, this software application provides our leadership team with full visibility of each business unit’s quote pipeline. Not only that, we use HubSpot’s real-time analytics to monitor quote volumes, win ratios, average quote size, etc. It’s enormously powerful,” Dumoulin says.

HubSpot servers are used for all broadcast communications, also. Precise Tooling has roughly 6,000 contacts in its contact database, each of whom is categorized based upon his or her product interest. This data set allows them to send targeted communications to subsets of their contact database, such as contacts interested in tool repair or ergonomic equipment. HubSpot’s embedded analytics provide open rates, the number of people who clicked or downloaded information and how much time was spent reading vs. glancing at the email.

“Our average open rate on broadcast emails is over 20 percent, which is high for any industry. We've been very successful in finding the right balance between type and frequency of information. And, we have tripled the size of our contact audience in five years,” Rowe says.

Precise Tooling recently retooled its website, too. It was relaunched late last year with an updated design and intuitive navigation system, as well as an expanded resource center with an RFQ feature, white papers, case studies, spec sheets, trade press articles, high-resolution photos of recent projects and several short video clips.

Additionally, Precise Tooling ‘soft-launched’ an online store in late December for its ergonomic workstations and lift tables on Amazon Business, which is a new and exciting distribution channel for the company.

Entering New Markets

Precise Tooling acquired the ErgoSmart business in October 2016 from a provider of plastics joining machines that started making ErgoStations as adjustable height tables and lift bases for their plastic joining machines. After 15 years, the previous owner ran out of space to manufacture the tables and, instead of expanding, decided to sell this portion of the business and focus solely on their top-of-the-line plastic joining machines. Don saw this as an opportunity to strengthen Precise Tooling’s brand as a specialty manufacturer and capitalize on the growing importance of ergonomics in manufacturing.

The adjustable-height workstations and machine bases can be adapted to hundreds of manufacturing applications. Here is an adjustable-height welding table, complete with a platen that rotates 360 degrees in both directions.

“ErgoSmart was an obvious business diversification and helps differentiate Precise Tooling as a specialty manufacturer,” Dumoulin says. “In addition to it being a complementary business, it validated our ability to integrate another business without interrupting the operating goals of our core business—mold building, mold maintenance/repair and mold productivity improvements.”

There are hundreds of different types of applications for these lift tables and bases, so they market the ErgoSmart brand to a wide swath of industrial buyers who have a need and interest in providing ergonomic equipment to their employees. One angle is savings as it relates to a manufacturer’s healthcare costs.

Precise Tooling uses several two-lift post ErgoStations or four-lift post ErgoBases in the workcells where craftsmen assemble ergonomic equipment ordered by customers. The company markets the ErgoSmart brand to a wide range of industrial buyers.

“We promote the value of an ergonomic approach to manufacturing equipment across different industries. Our best customers or potential customers are those who are taking a very proactive approach to the well-being of their employees from an ergonomic and worksite efficiency standpoint,” Rowe says. Interestingly, Precise Tooling itself uses 10 of their two-lift post ErgoStations or four-lift post ErgoBases in the work cells where they assemble ergonomic equipment ordered by their customers!

Supporting the Industry

Precise Tooling CEO/Owner Don Dumoulin met with Congressman Greg Pence in late December to discuss U.S. and China trade issues as well as the ongoing challenge of finding skilled machinists to support the company’s growth.

Dumoulin is a big believer in surrounding himself with people who are smarter than him because it helps a business run better, and this includes people outside of Precise Tooling.

“When you are a private business owner, you tend to be isolated because you're focused on your business, people and customers. So, to stay fresh, I try to stay actively involved in industry associations,” Dumoulin says. For example, he is on the board of the American Mold Builders Association (AMBA) and serves on the Ball State University Foundation Board. He also chaired the Purdue University’s Manufacturing Extension Partnership (MEP) and still sits on the board, which helped Precise Tooling win a workforce development grant from the State of Indiana in 2013.

“We also work with two local high schools and typically hire one or two of their best graduates every year. For example, Josh [Jeffries] was a graduate of that program. He started right out of high school, has been with Precise Tooling for 23 years and runs manufacturing operations organization for us,” Dumoulin says.

Another is Beau McKinney, who started with Precise Tooling as a high school junior and graduated last spring. Dumoulin is paying McKinney’s tuition at Ivy Tech Community College and expects him to become a mold leadman in about six months. “I wouldn’t be surprised to see him run this place someday,” Dumoulin says.

CELEBRATE PRECISE TOOLING SOLUTIONS DURING AMERIMOLD CONNECTS

Make sure to check out Precise Tooling Solutions’ showroom during Amerimold Connects, our answer to the industry's need for an event where the moldmaking community can connect in this challenging time of the COVID-19 crisis. We're taking the tradeshow experience and bringing it to your home office or shop June 9-13 in a virtual space. Attendees will be able to visit virtual booths hosted by exhibitors across the country, take part in education sessions and communicate with other attendees and exhibitors.

Register for free today and join us in celebrating this year’s Leadtime Leader Award Winner during a live awards ceremony, June 10 at 3 pm EST!

Related Content

What Do You Really Win as a Leadtime Leader?

MoldMaking Technology has honored many winners since the Leadtime Leader Awards launched in 2003, but what exactly do they win?

Read MoreMMT's Most-Viewed March Content: Digitalization in Tooling, The Leadtime Leader Awards & More

March was a big month for MoldMaking Technology. Not only did we celebrate our 25th Anniversary, PTXPO, and announced the return of the Leadtime Leader award, we also continued to cover some of your favorite topics. Take a look at what you might have missed in March.

Read MoreMoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

Read MoreHow Do You Win MMT's Leadtime Leader Awards Competition?

Find out how your shop can take the 2024 title, how candidates are assessed and how long the process takes.

Read MoreRead Next

Snapshot of Why Precise Tooling Solutions is MMT's 2020 Leadtime Leader Winner

Here is a quick look at some of the reasons this small specialty manufacturer took the title this year.

Read More2019 Leadtime Leader Winner Honored at Amerimold

Cue the lights, start the music and welcome to the stage MoldMaking Technology’s 2019 Leadtime Leader Winner: X-Cell Tool & Mold of Fairview, Pennsylvania.

Read More2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)