PODCAST: 3-in-1 Moldmaking Force Always Looking for Problems ... to Solve

This mold manufacturer considers itself an engineering company with a focus on people and solving problems. In this episode of The Manufacturing Alliance, I sit down with two VPs to break down how three companies operate as one to provide creative solutions to complex manufacturing challenges.

Share

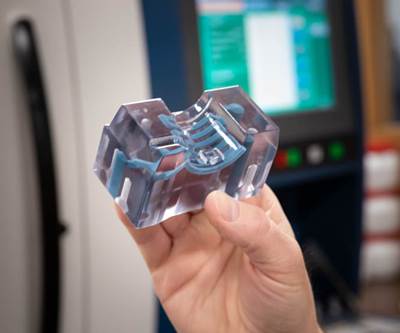

The mission of Minnesota-based Custom Mold & Design, Paradigme Engineering and Teamvantage is to help customers develop products, not just new molds. This effort involves 320 people across three facilities all involved in ultra-precision part and mold work for implants, surgical tools, pacemaker programmers, diagnostic equipment, hospital bed components and chemotherapy delivery systems.

How the team is able to accomplish all of this made for an interesting discussion during this episode of The Manufacturing Alliance Podcast with the company’s VP Lester Jones and Vice President of Sales Tom Caron.

This duo brings together Custom Mold and Design, Paradigme Engineering, and Teamvantage into a 3-in-1 precision and quality-focused company. These problem-solvers rely on relationships, collaboration, and providing win-win solutions. They take pride in the cleanliness of their shop and the never-ending support from their team. Lester and Tom’s story includes taking on new challenges and making all-star first impressions.

Here are some tidbits to whet your appetite for our nice 30-minute conversation:

- In reality, we are looking for problems … that builds relationships and grows the business.

- Provide creative solutions to complex manufacturing challenges.

- The entryway into the customer is solving a problem followed by a new product.

- Personal “Treat others the way you want to be treated ties.

- Quotes on shop walls provide inspiration.

- “You never get a second change to make a first impression.”

- Our medical work hits close to home.

- A fun new project is a multishot component that is being tested in the NFL to help prevent concussions.

- Our people are taking care of business every day.

- Lots and lots of tours, and we don’t have to prepare for a chance. We are always ready.

- Fits with our precision mold components and parts.

- Established environment to be clean and focused.

- Our folks come up and want to know what customers think of them after a tour.

- Cost constraints frustration lead to CMD explaining price points. Paradigme is plan b for a less expensive cost option.

- Helping to educate customers on the true cost of mold over life of the mold.

- If the price comes up in first five minutes, they are probably not a fit for us as a customer … we are all about relationship, collaboration for the right solution involving total cost

- Looking for opportunities to solve problems.

- We don’t like to do the boring stuff.

- A lot of effort goes into designing out the complexity to make simpler, cheaper molds, but CMD likes to keep the complexity in.

- A mold is part of a mold builder as it ships off to a customer; it’s like sending their child off into the big bad world.

- Image creation is key to trade show presence.

- Marketing efforts include a focus on social media.

- Adding another 20,000 square feet for tooling and machine to component capacity.

- Learning all the time about hybrid additive manufacturing.

- Need to respect the leap from subtractive to hybrid additive manufacturing as opposed to the leap from three-axis to five-axis machining.

- CMD uses a seasoned, diverse flexible team working on the Matsuura LUMEX Avance 25.

- Number-one challenge is growing people. You can buy machines, but building people is the real need.

- A dedicated trainer in-house as well as an outside third-party.

- Pause to figure out how the next-generation works.

- Owner Ray Newkirk has FOMO, so he is always involved. He cares.

- They key to everything is the culture, the team, collaboration, open and honest conversation to move in the right direction together.

For the full podcast click below:

For all of our archived podcasts, click here.

Related Content

Advancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

Read MoreTechnology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreFrom Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

Read MoreRead Next

Custom Mold & Design Chases Complex Mold and Production Part Projects with Top-of-the-Line Five-Axis, Screw, Mill/Turn, Additive and Molding Machines

Unique business model—with an eye on complex projects and an arsenal of machine technology to meet the required accuracy levels—raises the bar in mold and machined component manufacturing.

Read MoreMold Builder Learns How to Use Hybrid AM to Build Conformal-Cooled Inserts

It is one thing to understand additive technology, but it is another to know when to invest, who to partner with and how to sell its value.

Read MoreVideo: Custom Manufacturing Through 3D Printing

The founder of earbud manufacturer Normal describes how commonplace digital technology + 3D printing allow a consumer product to be tailored to the end user.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)